In today's competitive marketplace, process efficiency, reduced downtime and extended equipment service life can make a difference in profitability levels. Selection of the proper pumping equipment is key to optimizing process efficiency in the adhesives and sealants industry. While there are various options when it comes to pump selection, progressing cavity (PC) pumps offer versatility and efficiency advantages.

PC pumps are a unique type of positive displacement pump, capable of handling an array of fluids from clean, water-like liquids and shear-sensitive products to highly viscous fluids such as adhesives and sealants. The design of the PC pump differentiates it from other types of positive-displacement pumps, resulting in high-performance features that enable PC pumps to outperform their counterparts in a range of applications.

PC pumps are effective in handling adhesive and sealant applications, as they are designed to provide low shear rates; have the ability to handle abrasive, high-viscosity fluids; and deliver a predictable, non-pulsating flow. The dependable, highly efficient PC pump also has the ability to lift fluids up to 28 feet, pump fluids over a wide viscosity range and can handle fluid temperatures as high as 500

PC Pump Technology Advancements

Recent technology developments and manufacturing capability enhancements have advanced the initial design characteristics of the PC pump, improving performance and extending the range of applications that can be effectively satisfied in the adhesives and sealants industry. Advancements in pumping technology create much value for an end user and encourage the selection of a PC pump.Moyno Inc., a unit of Robbins & Myers Inc., is a leading manufacturer of progressing cavity pumps, having served the needs of the adhesives and sealants industry since 1936. The company has developed a new high-performance process pump for demanding applications.

Designed for highly viscous, abrasive, corrosive or high-temperature applications, the Moyno® PowerFlowTM pump outperforms alternative positive displacement pumps when handling adhesives and sealants, offering significant advantages in terms of versatility in application, performance, longevity, and efficiency.

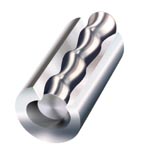

This PC pump incorporates hardened tool steel or hardened 17-4 pH stainless steel rotor and stator pumping elements, which replace the typical metal rotor and elastomeric stator combination normally associated with a PC pump. The required precision fit of the pumping elements was only made possible by the recent development of new, proprietary manufacturing process capabilities that ensure higher stator profile tolerances for increased pumping efficiency. The ability to maintain the required tight metal-to-metal profile tolerances also enables the pump to effectively handle thin, water-like liquids as effectively as viscous fluids, enhancing its application versatility.

Traditionally, the stator of a progressing cavity pump is constructed of an elastomer. While offered in a variety of elastomeric materials, the application of the PC pump remained limited in some applications by the compatibility of the fluids being pumped with the elastomeric material of the stator. All-metal pumping elements like those offered in the Moyno PowerFlow make the PC pump ideal for applications where heat, chemical or solvent compatibility with an elastomer is a problem.

The advantages of metal pumping elements are considerable for adhesive and sealant applications. Elastomeric stators do not permit PC pumps to handle the higher temperatures and pressures that the metal-to-metal pumping elements can, nor are they able to provide the broader material capability that the all-metal PC pumps can provide. This new generation of PC pump is not only powerful enough to generate flow under any combination of high pressure, high temperature and high chemical resistance, but it also retains the low-shear feature of the progressing cavity design. The low-shear feature allows this PC pump to effectively handle adhesives, fillers or additives that are shear sensitive, minimizing foaming and product degradation.

The close tolerance, all-metal pumping elements take much of the credit for allowing a PC pump like the PowerFlow to handle high-viscosity fluids and high-pressure conditions such as those found in the adhesives and sealants industry. Handling temperatures for grades of hot-melt adhesives can range to 400

Mechanical Seal Technology Advancements

A key component that can lead to failure in any pump is the mechanical seal. Another recent innovation that offers significant benefits when pumping adhesives and sealants is the heavy-duty, proprietary Moyno®PowerSealTM, which increases sealing integrity in PC pumps and enhances longevity. This seal was developed for applications involving high viscosity and abrasive fluids like adhesives and sealants. In critical situations, this rugged seal can perform in fluid temperatures up to 500

Conclusion

High-performance PC pumps with close tolerance, all-metal pumping elements offer application versatility, performance efficiencies, minimal maintenance and long life in adhesive and sealant applications. Combined with field-proven dependability and an economical total cost of ownership, PC pumps may be the best overall solution for adhesive and sealant pumping applications. PC pumps are designed to provide low shear rates, have the ability to handle abrasive, high viscosity fluids, and deliver a predictable, non-pulsating flow.Recent advancements in PC technology and manufacturing capability enhancements have resulted in an advanced line of PC pumps that use close-tolerance, metal-to-metal pumping elements to extend compatibility with a broader range of adhesives, sealants, additives, fillers, and solvents. These new designs also increase the temperature range of the adhesives and sealants that can be handled to 500

For more information on pumping equipment, contact Moyno Inc., PO Box 960, Springfield, Ohio 45501; phone (877) 486-6966; fax (937) 327-3572; or e-mail info@moyno.com .