Air, water, fire and earth are all necessary for the survival of mankind. However, these same necessities can also prove to be sources of great destruction when out of our control.

The same principle holds true for the most ubiquitous creature on earth, the microorganism. Both harmful and beneficial microorganisms exist everywhere that water and appropriate nutrients are available for their growth and survival. Harmful microorganisms, therefore, pose the greatest threat in our environment. How, then, do we maintain control? We must live in harmony with nature, by striking a balance between its beauties and protecting ourselves from its many dangers.

Chemists, biochemists, and microbiologists have sought ways to maintain this balance. Over the years, these scientists have developed chemical agents - known as antimicrobial agents, biocides or preservatives - to combat the growth and proliferation of harmful microorganisms in various industrial applications. Adhesives and sealants formulators use these chemicals in accordance with requirements and guidelines in everyday situations to either control or kill these microscopic pests.

A substantial amount of money is lost every year due to microbiological contamination of adhesives and sealants in their manufacturing facilities. Since contamination by microorganisms can occur at various points before, during and even after manufacture, early use of an effective preservative is essential.

The proper selection of a preservative and knowledge of their interaction with other materials is crucial. The key to formulating is to understand the function of an additive and its chemical or physical behavior in the presence of other components in the adhesive or sealant. This is often not easy or simple. Sometimes very minor amounts of the preservative can have major effects on the adhesive, sealant and final product performance. The complexity of the biocide, and what happens at the interfaces of each, is of critical importance.

The function of a biocide added to an adhesive/sealant formulation can generally be categorized into two main areas.

1. Preventative - prevents a potential problem

2. Corrective - corrects a problem in the manufacturing stage

The performance of a biocide is dependent upon a combination of microbiology and chemistry. Each class of biocide molecule has a killing action, based on its chemistry, which is either quick or slow acting, and will work vs. a broad or narrow spectrum of microorganisms.

There are four main factors that affect biocide performance in a system: system conditions, compatibility with the system, microorganism type and microorganism strength. One of the most important and easy to differentiate system conditions affecting biocide performance is pH. Each biocide has a pH range in which it is most effective. Outside this pH range, biocidal activity may be weakened. Other factors basic to the system that affect performance of a biocide include temperature, raw-material components, and exposure to contamination during manufacturing and storage. In addition to individual raw materials that may be difficult to preserve, some chemicals will deactivate a biocide. Because of their reactive nature, biocides can be affected by oxidizing and reducing agents, and other reactive chemistry such as surfactants, used in the manufacture of products.

The most critical factor affecting biocide performance is the ability to control an organism. There are three classes of organisms that a manufacturer must control: bacteria, yeast and fungi. A product that controls only bacteria is considered narrow spectrum; a product that can control all three is considered broad spectrum. Each biocide will be more or less effective against specific microorganisms, and in some cases will be ineffective even at high dosages.

To approximate how a biocide will perform in the field, biocide suppliers run laboratory tests under conditions that best approximate actual long-term exposure. An effective test method will indicate to a supplier the appropriate dosage level to return a system to sterility and/or keep a product preserved against further inoculations of microorganisms.

Product Failure

While the chemistry and performance of biocide actives is an exact science, the field efficacy of any biocide can vary significantly. Because of the vast number of changes in climate, raw-material quality, production variances and human error, explaining product failure is something that every manufacturer and biocide supplier faces.Across applications, the most common rationalization of biocide failure (after a period of demonstrated success) is that the microorganisms in the system have mutated and become resistant to the biocide. This belief has resulted in the fairly common practice of biocidal rotation. Many suppliers will switch biocides every 6 months to two years even if there have been no outbreaks. They believe that switching products does not allow resistance of the microorganism to occur, and stopping such perceived resistance ultimately reduces the chance of contamination.

In actuality, biocides mainly fail when there is a change in the system they are protecting. The changes can be major and obvious, or so subtle that they may be nearly impossible to detect. An obvious example of change that can precipitate failure is the replacement of a raw material with a similar raw material from another source. Regardless of the cause of failure, fast and thoughtful action on the part of the biocide supplier is just as important to a manufacturer as finding the answer to the problem when trying to maintain a solid relationship.

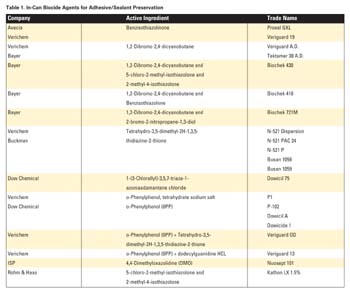

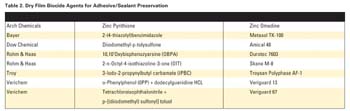

Most major suppliers of biocides to the adhesives and sealants industry are focused on market niches where they can successfully differentiate themselves on performance, service or product offering. The current trend is to follow a product-driven approach. Today, suppliers are recognizing the demands of adhesives and sealants formulators and are delivering products that address their needs. There are many biocides used for in-can and dry-film protection of adhesives and sealants. Although no single active ingredient meets all of the requirements of an ideal biocide agent, Tables 1-2 list the most commonly used biocides for preservation.

Biocidal Products

Biocidal agents are available to work both in the can or batch and in the dried film. For this reason, many manufacturers include a biocide agent in the formulation of the adhesive and sealant so it can kill both bacteria and yeast that can be present.The biocides used in the adhesive and sealant market can be grouped into two classes - in - can preservatives and dry film fungicides/mildewcides.

In-Can Preservatives

These are chemical compounds that are added to formulations during manufacturing to prevent biodegradation. Bacteria and yeast are often introduced and can come from the raw material or from poor plant hygiene practices. A number of chemical actives are used for prevention of in-can microbial growth. The antimicrobial is usually added as early as possible in the production process to prevent in-can growth of undesirable organisms. The problem is more serious in the case of waterborne systems than for solventborne systems, as the presence of the solvent tends to act as a deterrent for microorganism growth. In-can preservatives for waterborne systems are used to protect latex-based products. Such adhesives and sealants are susceptible to microbial attack because of the presence of biodegradable emulsifiers, stabilizers, and cellulosic thickeners.Dry Film Fungicides/Mildewcides

These chemicals are used as performance additives in both aqueous and solventborne systems to inhibit fungal and algae growth in the dry adhesive film as a means of protection against premature adhesive failure. The growth of organisms, such as mold, mildew and algae, is very undesirable from an appearance point of view. These organisms also cause the physical breakdown of the adhesive film, which can lead to an increase in porosity of the surface of the film and subsequent loss of adhesion to the substrate. Moisture also may contribute to the growth of fungus, which can decay a wood substrate. The main requirement for a dry film biocide is low water solubility. The biocide is designed to prevent contamination of the adhesive film over time, and it is essential that the active ingredient is not leached out from the adhesive. Due to the requirement for fungicidal and algicidal activity, combinations of biocides are usually used.Key Success Factors

The key developments driving the sales of biocides to the adhesives and sealants market include the following.- EPA guidelines continue to affect product mix, as does the European Union's Biocidal Products Directive.

- Producers seek new geographic markets and application areas for their existing product lines.

- Companies introduce blended products, which incorporate more than one active ingredient, rather than entirely new product types.

- Water treatment companies strive to become full product and service providers.

- Conglomerates spin off specialty chemicals businesses.

- Biocides will continue to compete with other products and technology, such as hydrogen peroxide, ozonification, ultraviolet light treatment and aseptic packaging.

Reputation, relationship building and persistence are the key to winning business in the adhesives and sealants biocide market. With an unchanged and limited number of active biocides available, manufactures are familiar with most products in the market, and have most likely tried a great number of them in their system. Even with this familiarity with the products, manufacturers have a hard time evaluating biocide performance because, at one time or another, biocides may fail. Manufacturers look to suppliers for assurance that a biocide will effectively provide protection to their products, but proving the efficacy of a product is a tricky exercise that involves extrapolating laboratory data to field performance, with little margin for error. A recommendation that does not provide adequate protection can prove disastrous to a customer's product line and a supplier's reputation, but overly cautious dosing recommendations will rarely prove cost-effective.

The single most important factor for success in the selling cycle is the relationship between the supplier and the customer. A biocide supplier is most vulnerable when a contamination problem occurs; the relationship between supplier and customer dictates what a customer's response will be when the inevitable happens. Manufacturers will either work with the supplier to solve the problem, bring in other suppliers to compare results, or switch suppliers without notifying the supplier that they had even had an outbreak. A good supplier/customer relationship can also give the most crucial advantage in penetrating new business - notification of problems with a competitor's biocide. This is the most vulnerable time for a supplier and must be capitalized on almost immediately. The opportunity to prove efficacy of another product in addressing the problem exists only as long as it takes the current supplier to offer a reasonable explanation of the failure and a solution to the problem.

Adhesives and sealants formulators need biocides, fungicides, algaecides, preservatives, mildewcides and the like to keep their finished products on par with current and future performance requirements. Therefore, adhesives and sealants manufacturers spend a substantial amount of money on these raw materials. However, restrictive environmental legislation, increased consumer awareness of the deleterious effects of mold and mildew, and the prohibitive cost of registering new actives are some of the issues facing the biocides market today.

Despite the obstacles, world demand for biocides used as preservatives in the adhesives and sealants market is projected to increase 6.3% per year through 2006. A number of developments are expected to drive the biocides market, including an increase in construction and, consequently, an increased demand for adhesives and sealants, which in turn will generate the need for greater quantities of in-can preservatives and dry-film fungicides. The continuing shift toward waterborne adhesive and sealant formulations will also help boost biocides demand because waterborne adhesive and sealants are usually more susceptible to microbial attack. Current products have different strengths and weaknesses and often do an effective job of preserving and protecting, provided they are used selectively. To extract the maximum benefit from a given biocide, it is essential to underpin traditional microbiological skills with expertise in organic, physical and analytical chemistry.

For more information on biocides, contact Verichem, 3499 Grand Ave., Pittsburgh, PA 15225; phone (412) 331-7299; fax (412) 331-7884; or visit http://www.verichem.com .

Bibliography

John Wiley & Sons Inc., "Industrial Antimicrobial Agents, Applications and Markets in Various Global Regions," 2000."North America Specialty Biocides 2000," Market Analysis, Kline & Co. Inc., 2000.

"Disinfectant & Antimicrobial Chemicals," The Freedonia Group Inc., Market Analysis Report, July, 2001.

Russell, A.D.; Hugo, W.B.; Ayliffe, G.A.J. "Principles and Practice of Disinfection, Preservation and Sterilization," 1992.

"U.S. Specialty Biocides Markets," Frost & Sullivan Market Report, 2001.

"Strategic Review of the Impact of the Biocidal Products Directive," Frost & Sullivan Market Report, 2001.

Ash, Michael; Ash, Irene. "The Index of Antimicrobials," 1996.