Where else can a company turn for meaningful cost savings? This article explores an underexploited, yet widely available, option for companies producing formulated products. This cost-saving opportunity is hidden in the product formulations themselves-truly the goldmine in an existing product line.

Out-of-Control Formulations

Many successful commercial products have raw-material costs that are 5-, 10- or even 15% higher than necessary. Month after month, these products are shipped out the door and deliver a portion of a company's profit to its raw-material suppliers. Recovering this lost profit often requires changing old habits and transitioning a company's attitude toward formulation from believing it is an art to knowing that it is a science.Why do many products have unnecessarily high raw-material costs? There are a number of reasons, which vary from company to company and product to product, but generally fall into three categories. First, the products were never cost-optimized before going to market. The underlying reasons are familiar to everyone involved in the development of new products. A market opportunity has been identified, customers are waiting, and being first-to-market has been proven to have a real payoff. As soon as a formulation is developed that meets the requirements and is manufacturable, the race is on to take it to market. After all, it can always be refined later, right? But once in the market, it is never fully and scientifically optimized for lowest cost.

The second source of excess raw material costs is the seemingly inevitable "formulation creep" that starts when a product is introduced and continues until it is replaced or retired. Raw-material costs fluctuate relative to each other, additional materials are added to address problems or customers' requests, obsolete components are replaced with new ones and, before you know it, your formulation has morphed into something quite different-and often more costly.

The third (and most insidious) reason for excess raw-material costs is the unwarranted mystique that surrounds the formulations themselves. If they are successful and profitable, the institutional folklore surrounding them grows and grows until they take on a magical life of their own. The longer they are in the market, the worse it gets. Over time, they come to be regarded as the only formulations that could possibly work, the brilliant brainchildren of long-gone formulators of mythical proportions, untouchable and unassailable by the mere mortals currently toiling away in their shadows. In short, these legendary gems are not broken and they cannot be fixed, and those elusive profits keep right on being shipped out the door.

The Fallacy of Cherry Picking

If a company wants to recover the lost profits from its current commercial products, or optimize new products before introducing them, it should never settle for the tired old technique of "cherry picking." This is the process by which an attempt is made to replace one or two raw materials with less expensive alternatives by direct substitution in the formula, leaving other ingredients alone. It is the easiest approach to cost reduction, but certainly not the most effective. Cherry picking perpetuates the myth that the formulation is magical and should be tinkered with in only the most gentle and unobtrusive fashion. In fact, every formulation is a complex, interactive system, and the real improvements are made when the role of materials relative to each other is defined and understood. This means that the lowest-cost formulation is often one in which the levels of some ingredients are increased while others are lowered, an outcome that cannot be arrived at by cherry picking.A Conceptual Model of Cost Reduction

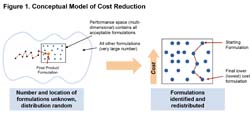

It is useful to reduce the cost-reduction challenge to a conceptual model as a way to introduce the elements of a successful methodology to achieve cost reduction. This model is illustrated in Figure 1.The left side of the figure represents a formulation prior to carrying out a cost-reduction program. We know that the formulation was originally developed through an iterative product-development process that brought it into a multidimensional "performance space," which contains our formulation and all other (unknown) formulations that meet the product requirements. What we do not know is how many other formulations share the space, the overall size and shape of the space, or where our formulation resides within the space. The objective of the reformulation exercise is to define this critical space, identify other formulations that reside in the space and order them with respect to cost so that we can choose a lower (or the lowest) cost alternative. The right side of Figure 1 represents the end of the reformulation activity when the starting formulation has been replaced by one that also meets the performance requirements, but has a lower total cost.

There are two important additional points to make with respect to this model. First, it assumes that many other formulations can meet the performance requirements. We have always found this to be true. It also seems to be true that the number of available formulations increases with the complexity of the formulation. The second point is that our starting formulation is not likely to be positioned at the bottom of the cost distribution since we did nothing formal during its development to characterize the space with respect to cost. Hence, we can almost always expect to realize cost savings.

The Five-Part Methodology

The discussion above reflects a transition from depending upon formulation folklore and myth to recognizing that formulation is a science that is amenable to rational discovery processes and rigorous analysis. This transition can be achieved by adopting a carefully developed methodology for "scrubbing down" a formulation in such a way that all its components are examined and the cost-performance tradeoffs are identified and understood. Only through the use of a sophisticated, statistically driven and analytically intensive methodology is it possible to lower costs and maintain equivalent performance.As a result of many years of developing formulated products in numerous product categories, we have evolved a methodology for accomplishing formulation optimization that is based on the integration of five tools.

1. Cost Leverage Analysis

We use a proprietary program to identify high-leverage formulation changes that are top candidates for experimental evaluation. The inputs to this analysis are the costs of each component, the levels of each component, the estimated amount of change possible in each component and the estimated impact of that change on performance and on the levels of other components. This process allows us to focus essentially all our efforts on formulations that are lower in cost than the starting formulation.

2. Statistically Designed Experiments

The importance of this tool cannot be overestimated. If a formulation has 15 to 20 materials, and just two levels of each ingredient are examined, there are over 2 million possibilities to consider. Experimental design, in combination with the other tools described here, allows a relatively small subset of this universe to be tested. More than one variable can be examined at a time using experimental design, and interactive effects that are subtle and difficult to detect are revealed in a way that separates signal from noise.

3. Subsystem Analysis

Subsystem analysis recognizes that complex formulations are often made up of subsystems that can be partially optimized by themselves. For example, it is sometimes possible to study a resin system, a curative system, a plasticizer system, or a solvent system in the absence of some or all of the other systems. When carefully designed, this approach can streamline the path to a solution.

4. Advanced Testing Techniques

Performance testing of sophisticated formulated products is the complex and time-consuming reality of reformulation programs. Our methodology recognizes that accurate and predictive testing is an essential component to success. We carefully identify the performance tests that are most critical to success and that provide the most differentiation between alternative formulations. We use sophisticated statistical and analytical tools to extract the maximum possible information from accelerated test results so we can estimate the outcomes well before all test specimens are completed.

5. Formulation Modeling Routines

As a reformulation program proceeds and a body of data is generated, it becomes more possible to use computer modeling to increase our understanding of the overall system. Performance

surface maps can reveal beneficial interactions between ingredients and illustrate regions where a given formulation is too sensitive to small changes to be acceptable.

The Bigger Picture

The goldmine in a company's product line is not just limited to cost optimization. The techniques described in this article can be just as easily used to improve the performance of any product with respect to a critical requirement, perhaps expanding market share or allowing a company to introduce a premium product in the process. And, when it comes time to enhance the "green" content of products, this methodology can be a fast track to achieving an improved formulation with cleaner raw materials.

For more information on reformulating, contact TIAX LLC, 15 Acorn Park,

Cambridge, MA 02140-2328; phone

(617) 498-5000; or visit www.tiaxllc.com.

Sidebar: A Success Story

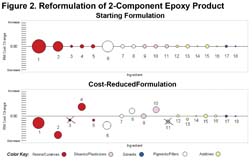

We recently used this methodology to reduce the raw-material cost of a two-component epoxy product that had been in the marketplace for many years. The reformulation effort took place over four months and involved preparation and testing of more than 90 formulations. Significantly, the methodology made it possible to focus exclusively on the compositions that had lower total raw material cost than the original product. At the conclusion of the effort, four alternative formulations were identified that offered raw material cost savings of 14-18%, and had equivalent or better performance. Since this product was the company's second-largest seller, the savings totaled over $500,000 per year.Figure 2 illustrates the change in the level of each ingredient that was made to achieve the cost reduction. In this representation, the size of each bubble corresponds to its contribution to total cost, and the displacement of the bubbles from the center line at the bottom indicates that the levels of some of the ingredients were increased while others were decreased or eliminated.

Some highlights of the program include:

- The cost savings were achieved without replacing any of the original raw materials. This minimized the impact on raw material inventory procedures and supplier validation. It is likely that a second-phase effort involving new materials could provide additional savings.

- Two of the original raw materials were found to be unnecessary and were eliminated from the product. This is not uncommon since formulation folklore usually includes unproven assumptions about the role of "critical" ingredients. Sometimes such ingredients are added to the formulation in an effort to fix customer problems or are the outcome of successful marketing by raw material suppliers.

- System and subsystem insights from the program could be directly applied to other products in the same family with minimal additional investment.

- The formulators responsible for this product observed that they would never have identified these savings opportunities using their conventional formulation techniques.