Knowledge of the rheological and mechanical properties of these varied systems is important in the design and optimization of flow processes for production and quality control, in predicting storage and stability conditions, and in understanding and designing the required end use mechanical properties.

To understand the formulation and performance of adhesive systems, one has to study surface chemistry, rheology and fracture mechanics with regard to the required structural design. Rheology has become an invaluable tool for tailoring the properties of the adhesives to meet required specifications by changing the chemistry of the polymer itself, the particle-size distribution (PSD) of suspension particles, the concentration of raw materials, etc. Rheological analysis can be used to optimize the controlling parameters for different processes in use, such as coating, calendaring and extrusion. Today, rheological instrumentation and rheometry are accepted techniques to more fully characterize, understand, and control the production and use of adhesives. How a particular chemical structure is studied or analyzed, the techniques and instrumentation involved, and how these may be used or modified to solve a problem are paramount in understanding the material-structure-processing relationships.

The flow of an adhesive into a substrate is a key parameter in defining adhesion property. Hence, a thorough knowledge of viscoelastic properties is critical to fully understand the adhesion process. The strength of this adhesive bond determines the ultimate peel strength. Thus, the viscoelastic properties' dependence on time, temperature and deformation are the factors to be analyzed.

Although adhesion rheology has been a subject of interest to rheologists for more than 40 years, there is not yet a precise testing protocol to study the properties mentioned previously. The gap between laboratory data and practical performance provides a window of opportunity to develop new test methods for characterization of adhesives. Dynamic mechanical thermal analysis (DMTA) has been the most successful method to closely correlate the rheological data with adhesive bond performance. Table 1 describes the rheological properties of interest for different adhesives.

This article will describe the rheological properties of a UV-curable structural adhesive (SA) and a pressure-sensitive adhesive (PSA), and correlate these measurements with end-use performance characteristics. The strong interest in the area of UV-curable SA was the result of the development of lower-voltage, lower-cost curing equipment. The short reaction time for adhesion on to the substrate is another key factor for the fast-growing interest in this area. For example, the reaction of isocyanates with polyols, which takes a few days, can be completed within a matter of seconds using UV.

PSAs are highly viscous elastomers at normal application conditions. The first PSAs were natural rubber with some terpenes and oils as tackifiers. The common way to describe a PSA is by analyzing its tack, peel strength and shear resistance. For PSA rheology, the main emphasis was the relation of pressure sensitivity with viscoelastic properties. Dahlquist3,4 has studied the relationship between tack and viscoelastic properties. Similarly, Class6, Aubery5 and many other rheologists have tried to correlate the rheological data with PSA performance. As mentioned, viscoelastic property characterization was found to be the most successful rheological tool to study the PSA's performance.

RHEOLOGICAL INSTRUMENTATION

In principle, the adhesion process can be followed easily by using viscoelastic and dynamic mechanical rheological measurements, as the formation of bonds between adhesive and substrate and the flow of an adhesive into substrate is reflected in the change of viscoelastic properties. Today, rheological instrumentation is considered a required analytical tool by scientists and is used daily. These research-grade instruments are Microsoft* Windows*-based, and measurements are made quickly and easily with the use of straightforward, user-friendly software. The operator simply loads the sample into the instrument and selects the appropriate experiment; the instrument does the rest.

Both the DYNALYSER and STRESSTECH are research-grade analytical instruments capable of measuring viscous, elastic and viscoelastic properties of liquids, gels, and solids. The instruments were developed for use by serious rheologists and provide a broad measurement range, spanning low-viscosity samples such as UV-curable monomers to more viscous products such as PSAs and SAs, two-component epoxy systems, gels, and prepregs through rigid, solid-state samples.

The STRESSTECH HR rheometer, equipped with optional UV cell and UV light source, is shown in Figure 3. The rheometer and integrated light source allow for user selectable illumination and exposure time and intensity. In addition, the environment and temperature around the sample can be controlled.

Results and Discussion

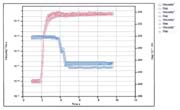

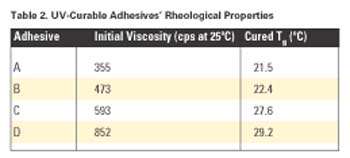

Structural AdhesiveTo study the performance analysis based on rheological properties of this type of adhesive, four different UV-curable laminating adhesives varying in composition were studied. The adhesives were first UV-cured isothermally at room temperature with a constant frequency of 5.0 Hz using a STRESSTECH HR rheometer equipped with a UV cell (see Figure 3). For the UV-curing study, a 25.0 mm upper parallel plate with a bottom quartz plate was used with a 0.3-mm gap. The samples were loaded with a constant force of 5.0 N using the rheometer's Quantitative Differential Pressure Normal Force Sensor. This was done to maintain the exact same loading history for all the samples. The test parameters were chosen from the linear viscoelastic (LVE) region of each material, followed by a "sigmoidal" deformation amplitude increase to compensate for the increase in stiffness of the material during curing. The samples were exposed to UV for 10.0 seconds at an intensity of 0.2 W/cm2. Using the Fast Oscillation program, the data rate can be adjusted up to 500 data points/second. Also, to compensate for the shrinkage of the samples during curing, the rheometer's auto tension feature was used, allowing for the rheometer to maintain a user selectable normal force during the curing phase by constantly adjusting the gap.

The UV curing analysis is shown in Figure 4 where all four adhesives cured within 2.0 seconds. There was more than four decades of viscosity rise upon curing and, at the same time, nearly 15% linear shrinkage in the sample for all the four adhesives.

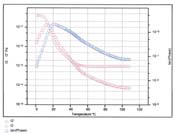

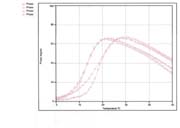

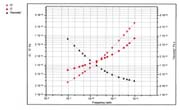

The glass-transition temperature (Tg) of the cured adhesives was determined from the peak in tan delta (ratio of loss (G") to storage (G') modulus. The results for all four samples have been plotted in Figure 6.

PSAs

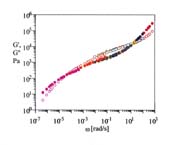

To study the relationship between viscoelastic properties and end-use performance of PSAs, a commercial packaging adhesive was studied. The samples were analyzed by DMTA using the STRESSTECH DMTA rheometer to study the thermal viscoelastic characteristics of the PSA. A temperature sweep from -65 to 120°C at a frequency level of 1.0 Hz and strain of 5.0 E-04 was conducted using eight 8.0-mm parallel plate geometry with a 2.0 mm gap.Figure 7 describes the storage modulus (G') and tan (phase) vs. temperature. The data analysis suggests that the dynamic properties of PSA strongly depend upon temperature. Although most PSAs are formulated to have a modulus value between 5.0 E04 to 5.0 E05 Pa at the use temperature, this particular PSA was formulated to have a modulus above 1E06 Pa for superior peel strength and creep resistance up to 100°C.

DYNALYSER and STRESSTECH are designed for testing any rheologically significant material, including the following.

- Thermoplastics

- Thermosets

- Elastomers

- Semi-Solids

- Fluids systems

Both the DYNALYSER and STRESSTECH are modular research rheometers with a range of measuring systems and accessories. Measuring systems are available as concentric cylinders, cone/plate, parallel plate, double concentric cylinders, sealed/pressure cells, and dynamic mechanical thermal analysis (DMTA) of rods, bars fibers and films. Special measuring systems for low volume, high shear rates and high sensitivity are also available. The measuring geometries can be made in stainless steel, titanium, polycarbonate or any user-defined material. The instruments come standard with patented differential pressure quantitative normal force sensors for reproducible sample loading history, thermal expansion measurements and quantitative normal stress measurements. The diffusion air bearing has a low inertia with high axial and radial mechanical stiffness.

The rheometers operate with a separate power supply unit that should be left on continuously. This reduces startup time and makes it possible for the instrument processor to maintain values for gap and other user defined settings.

STRESSTECH HR, the high-resolution version of the STRESSTECH rheometer, allows measurements at micro radian displacement and extremely low applied torque. Equipped with HR, the rheometer increases the performance specifications to the DYNALYSER level.

Temperature control cells are available using circulating fluid, Joule-Thomson Effect, and cryogenic covering the range -180 to 550°C. All measuring geometries are supported, including cone/plate/parallel plate, concentric cylinder, and solids in torsion and tension. A patented sealed cell for measurements under moderate pressure with full dynamic and steady shear capabilities - along with several high-pressure cells with an upper range of 5,800 psig - is available.

Rheometer Electronic Unit

The rheometer's electronic components are contained within the mechanical unit and the instrument is built around a dedicated high-speed 32-bit CPU. This consolidation enhances performance and versatility due to electrical connections on the motherboard bus rather than through cables to a separate electronics cabinet. In addition, valuable bench space is kept to a minimum. The motor control is based on digital drive technology. The unit comes with a built-in diagnostic system and a quick diagnostic service port for service engineers. Also included is a modem port for remote-control operation as well as fault diagnostics for service. The electronics power supply is designed to operate on a line voltage between 180-260V or 90-140V and an operating frequency between 47-63 Hz.RheoExplorer 5.0 Software Package

RheoExplorer 5.0 software is based on the Windows operating platform and runs under Windows 2000 or XP. The standard software package is a multi-tasking interface with selectable user levels. It is designed to provide flexibility for configuring and using the ATS RheoSystems/REOLOGICA Instruments' rheology system. The computer is not dedicated to simply running the instrument but is available for other uses while making measurements. The computer can be used for printing previous results, writing a report, or performing measurements with another instrument.The software enables a PC to be used as the interface to allow the user to control the instrument, and collect and analyze the resulting data. Viscometry, oscillation under stress and strain control, stress relaxation, creep and recovery, constant rate, yield stress, fast oscillation, process control, and project (multi- experiment linking), time temperature superposition, and spectrum transformation packages are available, allowing the sample to be analyzed by way of different rheological procedures. Powerful data analysis capability allows model fitting, graph and table customization, and exportation of results to all other Windows-based software.

RheoExplorer 5.0 includes the ability to link user-designed methods, including instrument setup and zero gapping using the project software. The dialogue windows have many storable, editable functions for unique testing requirements, and can be reset to default values using default buttons. An example is the oscillation frequency step measuring program where stresses, delay times, integration periods and sample sizes may be set individually for all frequencies. Another example is the zooming function, which is present in both viscometry stress step and oscillation frequency step, allowing any number of steps and increments to be selected. The instrument also performs controlled strain, and constant shear rate measurements, and comes with automatic gap adjustments and thermal expansion compensation using the patented differential pressure normal force sensor. The system enhances measurement reproducibility since the sample loading history is reproduced identically each time.

Applications-Specific Rheometers

VISCOANALYSER is a modular research rheometer system fully upgradeable to a STRESSTECH unit as the user's needs and requirements dictate. In addition, VISCOTECH (Figure 10) is a new entry-level research rheometer designed for routine viscoelastic measurements.Conclusion

This article reviews the important rheological characteristics for both structural and pressure-sensitive adhesives. The article also demonstrates the potential of ATS RheoSystems/REOLOGICA Instruments' Rheometers for a range of materials. In addition, a detailed interpretation of data and the correlation of the rheological response with the physical/chemical properties of different adhesives has been presented. The rheological characterization of adhesives provides important information for engineers and scientists to improve and optimize their products and manufacturing processes. Today, most researchers and manufacturers count on rheological measurements to develop customer-favored products with a competitive edge in the marketplace. A reliable research-level rheometer and a thorough understanding of rheological measurements are now a necessity for success in today's marketplace.For more information, contact Peter K.W. Herh, REOLOGICA Instruments, 52 Georgetown Rd., Bordentown, NJ 08505; phone (609) 758-1750; fax (609) 758-3498; e-mail info@reologicainstruments.com ; or visit http://www.reologicainstruments.com .