Benefits of UV-Laminating Adhesives

Laminating adhesives generally bond clear laminate plastic films to various plastic films, paper or metallic foil substrates. For this purpose, curing by UV and "dry" laminating adhesives is usually adequate. Upon curing, this type of adhesive offers a non-tacky film that bonds sufficiently to the respective substrates and achieves excellent T-peel properties. However, when a specific application requires laminating opaque substrates or films that exhibit adherence difficulties, EB-curing or PSA-type (wet) laminating adhesives may be necessary. After cure, this type of adhesive results in a tacky PSA-like adhesive. EB cure is not negatively affected by opaque substrates, and PSA-type laminating adhesives can be cured prior to the lamination.Targets

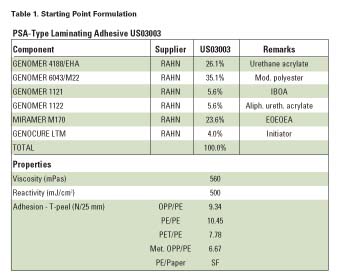

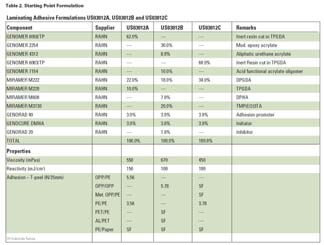

RAHN is a supplier of energy-curable raw materials used in finished formulated products. Our goal and interest lies in supporting industry needs with functional formulations that serve as starting points for specific projects. We have formulated four laminating adhesives with different end properties to suit industry needs (see Tables 1-2).Each adhesive offers the preceding properties at a film thickness of 0.3 mil (7.7 µm) on a substrate that has been corona-treated to 42 dynes/cm and cured through the laminate film using a 300 wpi (120 W/cm) Hg bulb.

It is not possible to have one formula for each individual substrate. However, one of the most versatile formulas is the wet-type LA US03003. For specific combinations of plastic substrates, see the tables.

Modifications to the Starting Formulations

T-Peel PropertiesPSA-Type Laminating Adhesive (US03003)

T-peel values are dictated by the elastic and adhesive properties of a laminating adhesive. GENOMER® 4188/EHA exhibited the highest peel results with each plastic film combination tested, resulting in exceptional elongation properties (384%) and good cohesive strength. This balance of flexibility and cohesion, coupled with excellent adhesion attributes, produces high peel values in a laminating adhesive. An increase in GENOMER 4188/EHA will raise the adhesive's T-peel performance.

In general, the best two monomers for T-peel strength properties were the GENOMER 1122 and the 1121. It is best to use them together. MIRAMER M170 offers lower T-peel but good cutting power.

Low-Cost (A), with PET (B) and with Non-PET (C)-Type LA

In all three formulations, an increase in the overall oligomer/monomer ratio will offer enhanced T-peel performance despite increasing the viscosity.For example:

- Additional GENOMER 6058/TP or small amounts of 6083/TP will benefit the T-peel properties of Formulation A.

- With regard to Formulation B, for a very rigid PET substrate, additions of GENOMER 4269/M22 combined with 1121 will assist in flexibilizing the adhesive; they also offer improved adhesion properties. For each formula, an increase in the amount of GENORAD® 40 will increase the T-peel performance through improved substrate adhesion. For the European market, ACMO has been observed as an exceptionally efficient diluent for laminating adhesives with excellent adhesive properties, especially with regard to PET-film combinations.

- For Formulation A, MIRAMER M170 is the most efficient reactive diluent for reducing viscosity.

- For all three formulations, MIRAMER M222, M200 and ACMO (for Europe) offer exceptional viscosity-cutting properties while maintaining good adhesion performance.

- MIRAMER M3130 and GENOMER 3364 offer higher-viscosity alternatives with increased reactivity and good adhesion properties, especially in the case of 3364 on treated PE and OPP.

Reactivity

PSA-Type Laminating Adhesive

Increasing the crosslink density will reduce peel strength, elasticity and adhesion. Be aware that the cure window of a PSA formula must be matched carefully. If it is not necessarily needed, do not use a higher dose of curing energy.

The following changes could be made without having a dramatic influence on the adhesives properties.

- In Formulation C, replacing a portion of the monofunctional GENOMER 7154 with trifunctional 4312 instead of hexafunctional MIRAMER M600 will help to maintain adhesive flexibility.

- Replacing GENOCURE DMHA with a more efficient photoinitiator like GENOCURE LTM or MBF will increase adhesive reactivity without a negative influence on the adhesive's properties.

- PET and other plastic films may absorb UV B and C. We recommend adding GENOCURE LTM or TPO, in this case in combination with a Fe-doped bulb.

Summary

The four LA-formulas are good for the following.- US03003: Low-viscosity PSA-type (wet) laminating adhesive with adhesion to a variety of substrates, including treated PET, PE, OPP, metallized foils and paper.

- US03012A: Low-cost, low-viscosity laminating adhesive for treated OPP, PE and paper.

- US03012B: Low-viscosity laminating adhesive for plastic film, paper and Al foil in combination with treated PET.

- US03012C: Versatile low-viscosity laminating adhesive for treated non-PET film, metallized OPP, Al foil and paper.

For more information, visit http://www.rahn-group.com.