In today’s global marketplace, industries are becoming more aware of the impact solvents and the use of heavy metals have on the health of employees, the environment, and the cost of waste disposal. With governing bodies like the Ozone Transport Commission (OTC) and the new United States National Emission Standards regulating hazardous air pollutants (HAPs), keeping up with the changing regulations can be a full-time job. That is why YUSA Corp., an industry leader in the manufacture of automotive rubber components, turned to LORD Corp. for help.

According to Terry Krebs, LORD Corp. Field Technical Service engineer, YUSA sought a way to lower its emissions while also improving its employees’ working environment. As both a manufacturer and user of a line of solvent-based, industrial adhesives used to bond rubber to metal, LORD Corp. has provided its Chemlok®line of products to YUSA since 1990.

Market Pressures

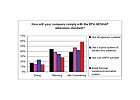

Krebs said YUSA is not alone in their quest. According to a survey conducted by LORD Corp. at the American Chemical Society (ACS) Conference in November 2005, companies are feeling the pressure to respond to changing regulations. Survey respondents - 23% of whom are in the auto industry, 5% in aerospace and 72% in other industries - cited price pressure due to global competition and environmental regulations (40% and 26%, respectively) as the key issues significantly affecting strategic decisions in today’s rubber industry, followed by employee health and safety (20%), and consolidation within the rubber industry (14%).The survey confirms that businesses are faced with the decision to install an incineration methodology or convert to products that do not contain solvents known to harm the environment. Based on the survey, regarding compliance with the Environmental Protection Agency (EPA) January 2007 National Emission Standard for Hazardous Air Pollutants (NESHAP) for the surface coating of miscellaneous metal parts and products, one can see the range of approaches companies are pursuing to meet or exceed the regulations.

“It does not appear as though there is an overwhelming trend among companies toward a common solution,” said Andrew Kintz, LORD Corp. Global Market manager-Automotive Components. “If companies currently have an incineration system, they are not motivated to change. Those wanting to change to aqueous-based adhesives believe them to be the long-term solution for a variety of reasons. Combining employee health with concerns for the environment illustrates why there is increasing interest in controlling the use of VOC-based solvents in the rubber industry.”

Answers for YUSA

Capitalizing on their experience, LORD began a series of audits of the YUSA facility in Washington Courthouse, OH, in 2003. The audits entailed all application areas of the facility in a joint effort to improve application techniques and the adhesive transfer efficiencies, as well as to improve the overall working environment for the employees.Krebs said the audits pinpointed several areas where application efficiencies needed improvement or equipment was in need of minor repair. Further, LORD recommended switching to Environmentally Preferred Chemlok®Adhesives (EPCA) to improve the working environment for employees and to reduce emissions. As a result of the findings, LORD provided training for all three shifts of employees with regard to the upcoming changes.

“Although many employees were nervous that the changes would result in a slower production cycle, they quickly recognized this was not the case and there was tremendous benefit to switching to more environmentally friendly products and processes,” said Krebs.

With the cooperation of management, line supervisors and employees, YUSA had a very successful transition to the new processing parameters established through LORD Corp.’s Process Review. YUSA and LORD will continue to make improvements in the processes as they are identified.

The result is a win for both the environment and YUSA employees. YUSA can now burn off their VOCs easier, and employees benefit with a cleaner working atmosphere. Transfer efficiencies of the adhesive to the coated parts also improved, resulting in less wasted product while maintaining the proper adhesive coverage on the coated parts.

“As the rubber-to-substrate adhesive industry works to control their level of volatile organic chemical emissions and to balance the increasing cost of raw materials with the pressure to reduce total costs in a struggling automotive industry, the options to make significant improvements in our business become very limited,” said Kintz. “LORD and YUSA have teamed to approach these problems in a unique manner. It requires a team approach, both supplier and manufacturer, to create value in systems that are already very lean. When LORD Corp.’s experienced field technical service people joined forces with YUSA’s excellent manufacturing personnel, the sum of the combined knowledge made this project a success.”

About YUSA Corp.

YUSA Corp. serves many automotive leaders in North America, including Honda of America Manufacturing, Honda of Canada Manufacturing, Mitsubishi Motors North America, General Motors Corp. and Ford Motor Co. When the company was founded in 1987, YUSA was a product of a joint venture agreement between the Yamashita Rubber Co. of Iruma-gun, Saitama Prefecture, Japan, and LORD Corp. The venture enabled YUSA to take advantage of Yamashita Rubber Co.’s technical expertise and gain the recognition and endorsement of LORD Corp.’s reputation in the international automotive and aerospace markets. In 1997, the Yamashita Rubber Co. acquired full interest of YUSA Corp. by purchasing the outstanding shares held by its venture partner, LORD Corp. For more information, visit yusa-oh.com.About LORD Corp.

With headquarters in Cary, NC, LORD Corp. is a privately held company that designs, manufactures and markets devices and systems to manage mechanical motion and control noise and vibration; formulates, produces and sells general-purpose and specialty adhesives and coatings; and develops products and systems using magnetically responsive technologies. With manufacturing in nine countries and offices in more than 15 major business centers, LORD Corp. employs more than 2,400 worldwide.For more information, visit www.lord.com.