Adhesive being tested in a chamber.

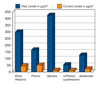

Figure. VOC Reductions for Key Chemicals of Concern

To address this indoor public health threat, sustainable building practices have evolved to ensure that buildings are designed, constructed and maintained in a productive and health-conscious manner. ‘Green Building’ principles focus on the reduction of environmental impacts associated with the construction of a building. Sustainable goals have gone beyond the traditional principle of reducing environmental impact to include improvement and protection of occupant health, as well as productivity and enhancement of indoor air quality. One of the most effective ways of achieving good indoor air quality is to choose and use those products that contribute negligible levels of VOCs into the air and to ensure that VOCs associated with the products are free of human toxicity. With increased market demand for green, healthy products for the indoor environment, adhesive manufacturers have retooled their formulations over the past decade, moving from traditional solvent-based adhesives to newer formulations made from soy or corn derivatives with increased water solubility. And, most importantly, this has been done while maintaining integrity of performance.

The United States Green Building Council’s LEED®programs and other green construction programs award credits for using low-emitting wet construction products, including coatings and adhesives. These products have been identified as potential contributors of VOCs to the air. Because these products are applied wet and require curing over an extended period of time, they have also been known to cross-contaminate other building materials and furnishings, resulting in longer-term interior contamination. A traditional VOC control approach has been to limit adhesives’ VOC content. While this approach may serve to reduce VOCs that contribute to industrial smog and ozone formation in outdoor air, it does not give a clear picture of VOCs that may result in indoor air. Techniques used to determine VOC content (measured in grams of VOCs per liter of adhesive, g/L) are not sufficiently sensitive to measure VOC emissions in the air at levels that may be irritating or toxic to people. As a result, evaluating VOC emissions from adhesives has become the preferred way of selecting environmentally friendly adhesives.

The most reliable and scientifically proven way to test for VOC emissions is to use environmental chamber technology. This method allows a product to produce emissions similar to the way a product would emit them when used in a home, office, hospital or school construction project. The measured data is used to determine levels of VOCs that will emit into the air following a prescribed application procedure with a defined application rate. These levels of VOCs are then compared to third-party certification program standards such as the GREENGUARD Children & SchoolsSMstandard, which requires that emissions meet the following chemical criteria.

- TVOC < 220 µg/m3

- Formaldehyde < 13 ppb

- Total aldehydes < 50 ppb

- 4-phenylcyclohexene < odor threshold (6.5 µg/m3)

- No carcinogens/toxins above accepted risk levels

- No odorants/irritants above acceptable levels

- No phthalates

Overall, the reduction in VOC emissions and odor related to adhesive usage is a positive step forward for indoor air quality and the health and well-being of building occupants. With the continued growth in green building programs and need for environmentally preferred adhesives, market demand will encourage innovation and differentiators.

For more information, visit www.greenguard.org.

SIDEBAR: Demystifying Green Product Certification and Standards Programs

According to theMcGraw-Hill Construction SmartMarket Report 2008, non-residential architectural and building contracting firms agree that they must shift toward green building - including the use of green building products to achieve energy efficiency, water conservation, and indoor environmental quality (IEQ) goals - in order to remain competitive. More than 50% of specifiers are incorporating green products into their building projects. However, making wise product selections is challenging, especially when confronted by myriad marketing claims, “green washing” practices and a lack of credible sources for industry-independent, third-party information.The report identified eight green product standards and certification programs as primary market movers:

- ENERGY STAR identifies efficient products that reliably deliver energy savings and environmental benefits.

- WaterSense identifies high-performing, water-efficient products and practices.

- Cradle to Cradle certifies products based on lifecycle of materials used to construct a product, as well as the overall lifecycle of the product.

- GREENGUARD Certification Program certifies products and processes for their low chemical emissions and low toxicity.

- Green Seal certifies products and practices for their low toxicity and overall environmental impact.

- GreenSpec Directory is a published resource on environmentally preferable products.

- Forest Stewardship Council (FSC) certifies wood products that come from forests managed to meet social, economic and ecological needs.

- Sustainable Forestry Initiative (SFI) certifies wood products that come from well-managed forests and responsible procurement practices.

The report includes an explanation of first-, second- and third-party certification programs, and describes how each green product program fits these definitions. The market’s desire for clarity, transparency and validity will increase the demand for green products meeting certifications based on sound principles, valid standards, and third-party verification.

For more information, visit www.aerias.org.