Pressure-sensitive adhesives (PSAs) are used in applications ranging from labeling food packaging to assembling electronic devices to mounting graphics displays. Although they have been around for decades and their use is widespread, manufacturers, converters, and printers may not understand the key differences between the adhesive choices available, how they’re constructed, or which are best suited for a particular job.

This article explains what a pressure-sensitive adhesive is, how it’s constructed and what adhesive options are available. The advantages and disadvantages of the primary adhesive types will be addressed, as well as how they are formulated and their common applications.

What is a Pressure-Sensitive Adhesive?

A pressure-sensitive adhesive is a material that holds two surfaces together solely by surface contact, which is achieved by slight initial external pressure. These dry adhesives require no activation with water, solvent or heat, and firmly adhere to many dissimilar surfaces with minimal pressure. Aggressive and permanently tacky at room temperature, PSAs can be used for bonding materials such as plastic, paper, metal, glass, and wood.

Pressure-sensitive adhesives offer numerous advantages. Application can be easily automated and usually requires no elaborate equipment. When used in assembly, PSAs save time compared to liquid adhesives because they don’t require any setup or long curing times. In addition, adhesion is immediate, allowing manufacturing procedures to continue uninterrupted, which results in significant time and labor savings. Pressure-sensitive adhesives eliminate the need for screws, rivets, clips or drilling holes, thus preventing cracks and corrosion and improving the integrity and appearance of the final product. PSAs also provide an insulating seal, as well as sound and vibration control.

Pressure-Sensitive Adhesive Constructions

Pressure-sensitive adhesives are available in four different product constructions; the most appropriate type depends on the application in question and the bonding requirements. The oldest and most commonly known type of PSA is an adhesive tape that winds onto itself without a liner; examples include masking tape, duct tape, cellophane tape and electrician’s tape.

A second type of pressure-sensitive adhesive construction is a one-side coated or single-faced product. This involves a flexible facestock coated on one side with adhesive. The adhesive side is protected by a release liner, which is removed when ready for application. Examples of this construction include protective overlaminates, labels, graphics or any application in which the face serves a unique function—whether it needs to be printable, decorative, or used for protection.

Another pressure-sensitive adhesive is a two-side coated or double-faced construction. With this type, the adhesive is applied to both sides of a carrier membrane (film, paper, foam, foil, scrim or cloth), then protected by a release liner. The two-sided constructions can be customized for an application by using a different type of adhesive on each side of the carrier membrane. Applications for these PSAs include situations where two substrates need to be bonded together—often replacing the use of mechanical fasteners or liquid adhesives.

The final example of a pressure-sensitive adhesive construction is a transfer tape or free film. This is simply a strip of adhesive that is wound around a release liner. It functions like a two-side-coated PSA in that it enables two substrates to be bonded together, but the transfer tape construction does not have a carrier membrane in the middle to reinforce the adhesive. The result is an adhesive strip that is more conformable and extensible, and can be made to almost any thickness to meet the specific application requirements. Examples of applications include the mounting of nameplates, construction of electronics or products with slim profiles, and decorative substrates.

Manufacturing Methods for Pressure-Sensitive Adhesives

There are four popular chemistries resulting in a pressure-sensitive adhesive laminate. One chemistry is achieved through the use of a solvent. With this method, the adhesive components (usually rubber or acrylic) are dissolved in a solvent and then coated onto a web. The solvent is then evaporated using heat and air flow, leaving a dry yet sticky adhesive (pressure-sensitive) that is wound in a roll.

Adhesives made with solvents often provide high performance, but can be expensive and require extra care because of processing restrictions. Special equipment is needed to properly dispose of the solvent, and there must be vigilant awareness of safety issues when dealing with solvents.

Another way to manufacture a pressure-sensitive adhesive is to create an emulsion (water-based). Here, the acrylic polymer and other additives are dispersed, not dissolved, in water and coated onto a web. Again, heat and air flow are used to evaporate the water before winding into a roll. Today’s water-based emulsions can often provide the same high level of performance as solvent-based acrylics and are generally a good choice when lower cost and safety are important, since water-based emulsions don’t require the extra steps that are needed with solvents.

The third method for creating a pressure-sensitive adhesive is developing a hot melt. Hot melts are typically a mixture of a polymer (such as thermoplastic rubber), tackifying resins and a hydrocarbon diluent (wax or oil plasticizer), which is heated until flowable. The hot-melt adhesive is then coated on a web and cooled before winding into a roll.

Hot-melt adhesives typically exhibit excellent adhesion to substrates and facestocks, have very good coatability, and are less expensive than most solvent-based adhesives. Drawbacks generally include processing and safety challenges, as well as difficulty performing under high temperatures. The major advantage of a hot-melt system is its lack of solvents and water - meaning it doesn't have to be dried in an oven. Hot melts are frequently referred to as 100% solids (no water or solvent) technology.

Finally, pressure-sensitive adhesives can be created through the use of a UV-curable adhesive. These adhesives usually require no mixing and cure in seconds when exposed to a UV light source. These environmentally friendly adhesives are reactive compounds that contain no solvents or other volatile substances. Because UV adhesives cure so quickly and at temperatures much lower than thermal heating, they can be used successfully on several heat-sensitive substrates such as plastic films, paper, and synthetic fibers. The quick curing minimizes shrinkage, providing the dimensional accuracy that is often called for in applications such as electronics manufacturing. UV-curable adhesives also offer durability, strength, insulation characteristics, and resistance to chemicals, moisture, and temperature. Like hot melts, UV adhesives do not require an oven.

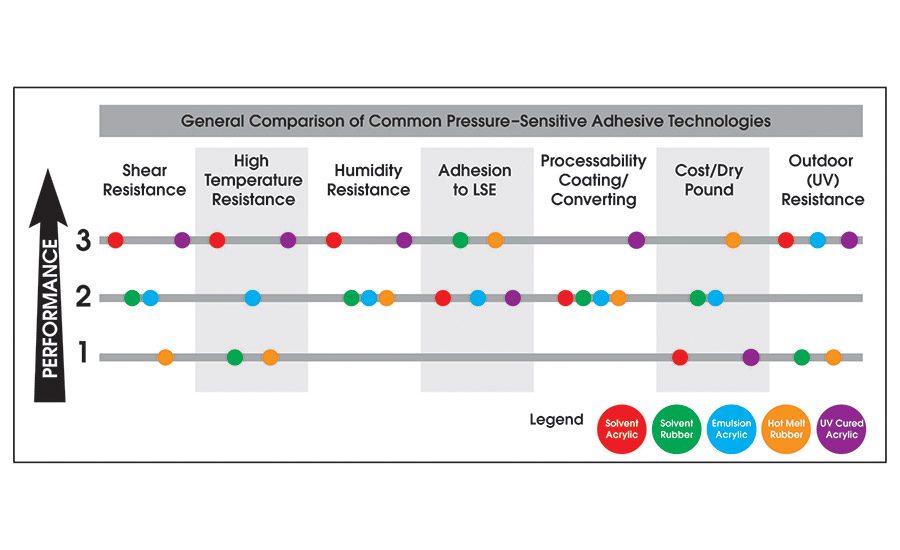

A decision on which method of adhesive manufacturing technology should be used for a particular application is determined by the performance characteristics needed.

Common Adhesive Types and Their Properties

In addition to considering the method in which the adhesive is created (solvent-based, water-based, hot melt, or UV-cured), it is important to understand the key adhesive component choices and how they will affect the pressure-sensitive adhesive’s performance in the application. The three main adhesive chemistry options are rubber/resin, acrylic and silicone.

For many years, rubber/resin formulations have been available that combine natural or synthetic rubber with tackifying resins, oils, antioxidants, or other ingredients as needed. They are typically either solvent-based or used in hot melts, and the aggressive nature of rubber adhesives makes excellent bonding easy to achieve.

These adhesives are known for their high level of adhesion to a variety of substrates and facestocks, as well as their high coatability. Rubber-based adhesives provide high tack and peel, and make excellent general-purpose adhesives, because of their ability to adhere well to several non-polar, low-energy surfaces, including polyethylene and polypropylene. In general, rubber-based adhesives are often a more economical choice compared to most acrylics.

Disadvantages of rubber-based adhesives include limited effectiveness when exposed to certain chemicals, UV rays, or high temperatures (over 150°F/66°C). In addition, they are more susceptible to oxidation and may darken, lose their tack, and become brittle if overexposed. Also, rubber/resin adhesives may turn soft and gummy if plasticizers, used in most polyvinyl chloride films (PVC), migrate into the adhesive.

The other type of adhesive chemistry commonly used in pressure-sensitive adhesives is acrylic. Acrylic adhesives can either be solvent- or water-based, and are formulated by reacting monomers with the desired properties, which are then typically crosslinked to form the type of polymer needed. Monomers are the building blocks of polymers and are considered to be either “soft” or “hard.” The combination of hard and soft monomers can be adjusted based on the level of adhesive (polymer) performance needed.

Crosslinking polymers improves the cohesive strength (internal strength of the adhesive, or the ability to stick to itself) of the acrylic formulation and can be accomplished in one of three ways: the use of thermal heat energy; by self-curing when a solvent is removed during the drying process; or through UV or EB non-thermal radiation.

In general, acrylics are relatively firm and durable, but are not as aggressive as rubber-based adhesives. An acrylic adhesive can be modified to alter its adhesion properties based on the selection of monomers used, the level of polymerization created, or by adding tackifying resins or other chemicals.

The advantages of acrylic adhesives are typically the opposite of rubber adhesives. Acrylics provide excellent temperature, UV and oxidation resistance; therefore, they are often the preferred choice for outdoor applications. They resist the negative plasticizing action that can occur with rubber and hold up well to chemical exposure. Acrylic-based adhesives are very durable and have clarity and color stability. Acrylics bond well to polar surfaces like metal, glass, polyesters and polycarbonates, and have high peel, tack, and shear.

Disadvantages of acrylics usually include poor adhesion to low-energy surfaces, such as polyethylene and polypropylene, as well as lower overall adhesion compared to rubber unless the adhesive is highly engineered. In general, acrylics are often more expensive than rubber-based adhesives.

Silicone adhesives are another chemical option for pressure-sensitive adhesives but are less common than rubber or acrylic. These specialized adhesives consist of silicone polymers that provide adhesion to silicon and other hard-to-adhere-to materials. Silicone-based adhesives can maintain adhesion over a range of temperatures; however, beyond their ability to adhere to difficult surfaces, their overall adhesive strength is low. Silicone adhesives are also more expensive.

Final Considerations

In addition to choosing the most appropriate adhesive formulation, construction and manufacturing method, a few other factors must be considered when selecting a pressure-sensitive adhesive. It’s important to know exactly what kind of surfaces or substrates the adhesive will be bonded to or will be bonding together (smooth, textured, even or uneven, high-energy or low-energy, porous or non-porous, etc.). The type of surface is a key factor in dictating which adhesive and construction will be most effective for the application. Knowing the surface properties will help address: adhesion requirements; thickness of adhesive needed; single-coat, double-coat, or transfer tape construction; and what kind of facestock or carrier membrane is needed.

The adhesive’s end environment is also a consideration, including whether the pressure-sensitive adhesive will be exposed to extreme cold or heat, sun and UV rays, humidity, flexing, water or chemicals. All of these can greatly affect the ability of the adhesive to maintain its bond. The length of time the PSA will be in use also determines how strong the adhesion needs to be for the application.

Choosing the most appropriate adhesive requires a lot of background work and careful consideration. The goal is to best match the needs of the application to the most suitable adhesive construction, while achieving the desired performance at the most reasonable cost. Always feel free to consult your adhesive supplier if questions arise or if consultation is needed to determine the best pressure-sensitive adhesive for the job.

For more information, visit www.mactac.com.