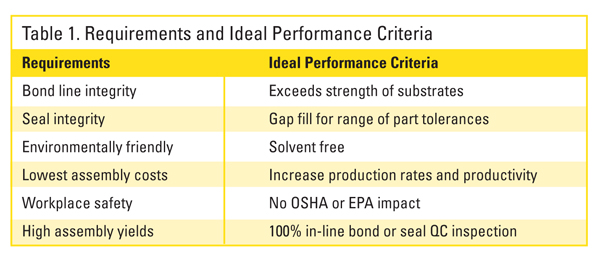

Selecting the right adhesive to meet the performance, production and environmental demands of an appliance assembly application can be challenging. Many factors must be considered before choosing a method to bond and seal plastic, metal, glass, or other substrates. Establishing the application requirements for the adhesive or sealant and identifying the ideal performance criteria provide the foundation for the selection process. Table 1 lists the major requirements and ideal performance criteria for adhesives and sealants used to bond plastic, glass, metal, or other substrates to similar or dissimilar materials.

Chemistry

Several adhesive chemistry options are available when bonding engineered plastics such as polycarbonate, acrylic, urethane, ABS, nylon, or other resin systems to other plastics, metal, or glass. Options include light-curable acrylated urethanes, cyanoacrylates, one- or two-part urethanes, and even a few hybrid combination adhesives like thermally curable and light-curable adhesives or light-curable silicone hybrid systems. Bonding to silicones is often best accomplished with silicone adhesives. However, under the right conditions, bonding to silicone elastomers can be done with urethanes.Viscosity and Thixotropy

Viscosity is the measure of a fluid’s resistance to flow. The lower a fluid’s viscosity, the greater its ability or tendency to flow or spread over a surface or bond joint. For example, water has a viscosity of 1 cP, while honey has a viscosity of 10,000 cP. Potting or filling a groove molded into plastic would likely require a low-to-medium-viscosity fluid, as a low-viscosity material will self-level and fill the groove without voids or air bubbles.An additional property for consideration is thixotropy. Materials that are thixotropic flow easily when placed under shear (e.g., during dispensing) but exhibit a higher viscosity when the shear force is removed (dispensing stops). For example, ketchup, which has a viscosity of around 10,000 cP and is thixotropic, flows easily when dispensed but stays in place on top of a hot dog. The thixotropic index (recovery) of a material is a helpful value. Typically, materials with values of 2-3.5 are very thick or gel-like, and materials with values of 1.5-2 tend to slump. A thixotropic material would be an ideal candidate to create a gasket bead profile on an unrestricted, open surface. This bead (which will act as a moisture, sound or chemical barrier) must be easily dispensed and maintain its profile prior to cure without the assistance of the assembly structure.

Adhesion

Once the adhesive chemistry is selected, an individual product within that adhesive class should be chosen based on its adhesion to various substrates. The test criteria are defined by the specific performance expectations of the adhesive based on the design of the components. Lap-shear testing or peel-force testing is common, as well as pressurization to burst or leak testing.The criteria for accelerated aging tests depend on the expected storage and in-use conditions over the life of the device. Attempting to speed up the accelerated aging test by using more aggressive conditions should be avoided. Conducting the test at too high a temperature may inaccurately characterize the adhesive by creating additional crosslinking within the adhesive, which, in turn, will cause a reduction in elongation properties.

Ease of Processing

If multiple adhesive choices still remain, evaluate the adhesive based on its ease of processing-one-part adhesives require a simple dispensing system while a metered mix system is needed for two-part adhesives. In addition, one-part systems usually do not require dispensing system purging or have issues with pot life. The ability to dispense and cure where and when needed make one-part acrylated urethanes ideal for many appliance assembly applications, requiring only that light (UV or visible) reach some portion of the bond line.Careful consideration of the assembly operation’s level of required automation (manual, semi-automated or fully automated) is also important. Can the system be easily stopped or shut off, or does a shut-down procedure need to be followed? Can the process be adjusted or qualified to handle lot-to-lot variation in viscosity or cure time?

Quality Enhancement

Since the quality and reliability of the appliance product is crucial, the ability to assure a high-quality adhesive bond is critical. Some appliance assembly adhesives are formulated to fluoresce under a black light, which enables quality technicians to confirm that the adhesive covers the prescribed bond or seal area while also being able to detect any leaks, air bubbles, or voids. Fluorescing adhesive formulations are available in both blue and red fluorescing color versions. Red is particularly useful in providing the proper contrast in situations where the surrounding plastics also fluoresce blue.A recent advancement* that further ensures joint quality is the introduction of technology that offers a blue color in the uncured adhesive that changes to clear/colorless once cure has been completed. A simple, post-cure visual inspection can thus determine the status of the adhesive cure.

Process Savings Opportunities

Process Savings Opportunities The true in-use cost of an adhesive should take all aspects of the process into account, including waste, downtime, start-up time, scheduled maintenance, tight quality specifications to minimize variability within the process, the number of workers required for a specific process, and scrap rate. While two adhesives may differ only slightly in their price per gram, one of the materials may deliver significant cost savings in process efficiencies.Cost savings in the assembly operation drop directly to the company’s bottom line and can be achieved in several areas. Potential accumulated cost reductions in these areas are illustrated in Figure 1 and can result in at least a 30% savings in overall process costs.

Material Costs

High-performance adhesives often cost more than commodity materials like two-part epoxies, thermally cured adhesives, solvent-based adhesives, or one-part moisture-cure silicones. Since light-curable materials are one-part formulations, they offer less material waste than two-part systems. With one-part chemistry adhesives, it is not necessary to purge the dispense system and dispose of the dispense tips or static mixing tips due to an incorrect mix ratio.

Assembly Labor Costs

Light-curable materials reduce labor costs by eliminating the expenses associated with stacking and racking parts of slow-curing adhesives. Light-curable materials cure on-demand, ensuring that the bonded appliance assembly is immediately ready for the next step in the process. Assembly labor costs can be reduced by up to 70% over two-part epoxy systems, two-part silicone systems, or one-part silicone systems.

Consider parts on racks awaiting their turn in a cure oven, cooling after the cure oven, or drying on racks for three to seven days. The labor associated with racking and loading into cure ovens is eliminated with the use of LCMs. Unlike other adhesive products, there is no need to be concerned about environmental conditions like high humidity adversely impacting the adhesive chemistry system.

QA Testing Costs

On-demand cure enables a quality assurance check of the bond line immediately following the cure, eliminating the retrieval of defective parts and minimizing scrap and work-in-process. The fluorescing of some adhesives allows for void or bubble detection. Manufacturers can then repair or scrap these parts before adding additional value to the part through down-stream operations. On a high-speed assembly production line, for instance, a high-speed camera can detect and confirm the post-cure presence of adhesive on the bond line through the fluorescing of the adhesive under black light.

Inventory Costs

The inventory costs associated with assembly processes using LCMs can be reduced by up to 50% over traditional adhesive chemistries. The reductions result from on-demand cure and instant QC testing, which eliminate excess inventory of slow-curing commodity adhesives. Light-curable adhesive systems avoid costly waste due to improper mixing of two-component systems and can minimize adhesive waste by eliminating the need to purge during startup, shutdown, and line-down scenarios.

Floor Space Costs

Since racking, batch process ovens and cooling racks are unnecessary, LCM assembly processes require a smaller footprint. In addition, the LCM assembly process offers compatibility with JIT manufacturing or Kanban production lines. Floor space savings provides the opportunity to expand the production operation and increases the value of product produced per square foot of floor space.

Multiple Benefits

Light-curable materials offer numerous opportunities to increase productivity and reduce waste in assembly operations. Instant on-demand cure, automated in-line inspection, solvent-free formulations, and the smaller footprint of the light-cure process are some of the benefits of LCMs that provide significant, positive impacts to the bottom line.*See-Cure technology from Dymax Corp.

For more information regarding light-curable materials, contact Dymax Corp. at 318 Industrial Lane, Torrington, CT 06790; (860) 482-1010; fax (860) 496-0608; e-mail info@dymax.com; or visit www.dymax.com.

Case History

A leading manufacturer of premium, portable, ruggedized safety flashlights used by firefighters, police officers, and military troops in the field experienced the benefits of a light-curable adhesive. During the development of its high-intensity series flashlights, the company was searching for a way to ruggedize the lens and reflector housings by applying a sealant to bond the sub-assembly. The company’s engineers needed the flashlights to withstand rough handling and extreme conditions in the field, and work in a wide range of environments like search and rescue or life-threatening situations.An LCM adhesive* was recommended to bond the glass lens to the reflector housing because of the adhesive’s ability to adhere dissimilar materials, its fast cure, and excellent adhesion properties. The rapid cure allowed the bonded parts to immediately move onto the next step in the manufacturing process. The lighting company experienced improved quality and process savings with the incorporation of the light-curable adhesive system.

*Multi-Cure® 621-T from Dymax Corp.