Figure 1. Pressure-Sensitive Material Production

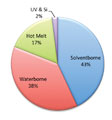

Figure 2. PSA Production by Region

Tape production accounted for 66% of all pressure-sensitive materials, while labels and graphics made up 28% and 6%, respectively (see Figure 1). In turn, the demand for pressure-sensitive adhesives (PSAs) reached $2.4 billion globally on the merchant market. This does not reflect captive production of adhesives by tape and label producers, which would add an additional 40-50% to the total.

The regional breakdown of merchant adhesives production shown in Figure 2 illustrates the emerging dominance of Asia Pacific’s producers, as they garnered 54% of the global demand. The Americas and Europe (EU 27) attained 22% and 21%, respectively, of the market share.

Figure 3. PSA Production by Market

Regulatory pressure will undoubtedly continue to create opportunities for environmentally friendly alternatives. Japan is reportedly promulgating two laws, which would create “black swan” opportunities for pressure-sensitive materials and adhesives producers by the end of the decade. The first will require the industry to lower volatile organic compound (VOC) limits to less than 120 parts per million, while the second is related to post-consumer recycling and will require producers of consumer goods-from autos to electronics-to disassemble and recycle their components.