Parachem® AC-7045 is an all-acrylic polymer emulsion that can be used in a variety of construction and pressure-sensitive adhesives (PSAs) and sealants. The emulsion’s proprietary manufacturing processes ensure that formulators can enjoy attributes such as higher neat polymer solids, viscosity and freeze-thaw stabilities on finished products and broader formulating latitudes.

Parachem AC-7045 is positioned at 65% non-volatiles, with a targeted viscosity value of 3,000 cps. The emulsion is anionic in nature, displays good miscibility in water and is tolerant to solvent additions. Its glass-transition temperature is -40°C and the emulsion has a mean particle size of 200 nanometers. Parachem AC-7045 is low in odor, exhibits excellent film integrity and displays aggressive tack.

Upon formulating, the emulsion exhibits broad stroke flexibility in allowing custom formulations to include higher carbonate filler loadings, mechanical stability and compatibility with standard industry intermediates. Integral to formulating, Parachem AC-7045 displays excellent self-thickening response while maintaining acceptable rheological profiles. Ammonia and/or higher boiling amines are used successfully to increase the pH from 5.0 (where the neat emulsion resides) to ranges of 7.5 or higher to optimize self-thickening, in-can stability, and reduce or eliminate the need for additional thickeners.

Built into the backbone of Parachem AC-7045 are resident components that not only provide excellent water resistance, but also allow this technology to be formaldehyde-free. In addition, Parachem AC-7045 is acceptable for the U.S. Food and Drug Administration’s CFR 175.105.

The balance of adhesion, dry tack and high shear strength is a valuable asset when formulating adhesives for multiple applications. Parachem AC-7045 can be tackified without losing a significant amount of cohesive strength with hydrocarbon and rosin ester tackifiers, which are typically used with acrylic emulsions.

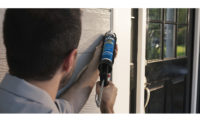

The polymer emulsion’s water resistance and plasticizer migration properties, along with adhesion tack, make it suitable for use in building and construction applications. Other markets may include flooring adhesives, roofing, film laminating and packaging.