Sausage packaging is quickly gaining interest in the marketplace, primarily due to growing environmental concerns. Sausage packages are often considered a greener alternative because they can be recycled once dispensed. European governments and agencies have developed regulations seeking to enforce the incorporation of greener materials and solutions, and the use of sausage packaging has become widely adopted as a result. As domestic regulations change, sausage packages will become more common in the U.S.

What Is a Sausage?

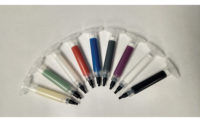

A sausage package comprises aluminum foil formed into a cylinder with adhesive tightly packed inside and sealed with an air-tight clip. As the sausage is dispensed, the foil film crumples in a fashion that leaves little to no material residue behind. One of the main advantages of sausage packaging is all that remains once the sausage is completely dispensed is a small recyclable aluminum disk, much like a crushed soda can. Depending on the geographic location, recycling can be very expensive for traditional adhesive cartridge systems, usually due to the amount of adhesive left behind in the cartridge or pail that could not be dispensed.Sausage packages can be considerably less expensive per ounce than conventional cartridges packages, mainly due to the cost of consumable materials. Savings as high as 60% over standard cartridges can be achieved. Sausages can be packaged into varied configurations and sizes, generally in the 10-30 oz range in diameters from 16-65 mm. Since the film is supplied on a continuous spool, manufacturers can make “on-the-fly” packaging changes with relative ease. This added flexibility allows manufacturers to package several different sizes of sausages without having to absorb expensive product changes or additional packaging component inventory.

Since the filling process generally entails less air entrapment, sausages tend to enjoy longer shelf life than conventional packages. However, a good rule of thumb when determining the best size for a sausage package is that the length should be at least 2.5 times the diameter.

New dispensing equipment is constantly being developed for this technology, but it is a good idea to select a size that accommodates readily available dispensing equipment. For example, one new package is available in a 300 ml sausage and can be dispensed out of a reusable plastic cartridge that is compatible with standard 10 oz dispense guns. Two-component sausage guns are also available, which enable many two-component adhesives to be sausage packed, including epoxies. Some dispensing manufacturers can also design custom tools to meet specific packaging needs.

The main disadvantage to the sausage package is that, once the material is cut and loaded into a gun, it must be completely dispensed and/or emptied. Sausages cannot be capped and stored for another use; they have to be used within the materials’ curing parameters. It is therefore critical that the material is sized appropriately so the consumer is not left with excess material and disposal issues.

In addition, it can sometimes be messy when removing the dispensed film material from the gun. Most materials can be packaged into a sausage, but some low-viscosity materials become problematic because most sausage machine equipment fills horizontally.

How to Package?

Packaging material into a sausage can be achieved through several paths. If you do not have access to the packaging equipment or do not want to make the large capital investment, outsourcing to a contract packaging company is recommended.Manufacturers should take several steps before introducing a sausage package to the consumer. Regardless of the material going into the package, it is industry standard to go through an evaluation period to determine if there are any negative factors relating to the material, film, shelf life and/or stability. To expedite this process, an accelerated aging test can be used to determine the material’s interaction with the film over extended periods. A packager or manufacturer will typically run multiple lab samples to complete the evaluation tests. This is also gives the manufacturer time to evaluate the completed product and make any necessary changes to artwork or graphics before production begins. Film can be ordered with artwork, or limited graphics can be applied during production, in some circumstances.

Sausages can provide a very simple adhesive package if the application is a fit. They can be packaged in diameters of 16-65 mm, with theoretically no limit on length, though manufacturers must consider what equipment is readily available to the consumer (e.g., dispensing guns and nozzles). Sausage packages are becoming more common because they offer valuable green benefits over traditional packaging. However, the application must meet certain criteria in order for sausages to be a true fit.

For more information, contact Accumetric LLC at 350 Ring Rd., Elizabethtown, KY 42701; phone (800) 928-2677; fax (270) 765-2412; email sales@accumetricinc.com; or visit www.accumetricinc.com.