Expandable cavity sealers have become a critical component of the overall acoustic package that has contributed to the documented noise reduction in passenger car applications over the past 20 years. Solutions encompass a variety of technologies, some of which are highly engineered parts and assemblies. As the market for smaller and more fuel-efficient vehicles expands, design architectures of the vehicle platforms are evolving to include body designs with smaller spaces between adjacent layers of sheet metal.

As this space, or cavity, between adjacent layers of sheet metal shrinks, the complexity of components that must be integrated into the space increases. Sophisticated arrays of airbags, corresponding wire harnesses, and water management tools are now standard requirements in the design process. To manage the complexity of these lightweight, fuel-efficient vehicle architectures, new engineering design solutions are required to meet ever-increasing and stringent acoustic requirements.

The supply base of acoustic products to the OEMs has also matured, creating a very competitive environment, both regionally and globally. Design solutions that go beyond the basic functionality of a cavity filler are becoming more common. In one recent example, a design challenge presented by an OEM required improved visibility for the driver. Here, the hardware to direct water drainage is moved from outside the windshield pillar cavity body metal to inside the cavity metal. A new cavity filler solution is conceptualized to manage this unique packaging and acoustic performance need. Although it is in its infancy, the innovative solution, along with other means of water management, have been measured for insertion loss, compared and presented.

Figure 1. Evolution of the Acoustic Baffle

An Evolving Market

As consumer and testing demands for performance grow, vehicle designs continue to drastically improve to meet new safety and fuel economy regulations. These regulations put pressure on OEMs to streamline vehicle design. Innovative automotive body design and assembly practices result in a complex arrangement of interconnected channels and cavities. These channels become efficient paths for noise to propagate around the perimeter of the passenger compartment once it is introduced into the body.1Acoustic baffles are used to reduce the transmission of this noise into sensitive areas, including the upper body structure, where acoustical breakout (noise penetration) through drain and access holes in the body are attenuated only by the acoustical properties of the interior trim components. The variety of potential paths by which sound is propagated throughout the upper body structure requires the baffle package design be evaluated as a system for acoustic and water management.

As automakers continuously refine their cars, trucks and SUVs, design capabilities and material science technologies of acoustic baffles become an engineering challenge to fulfill these refinements. Early part designs were cumbersome, bulky and not very efficient in overall performance. A full layer of expanding material was often assembled onto a metal or plastic bracket that functioned as a shelf to span the cavity section to be sealed. These parts were often welded or clipped to the body structure with plastic pins.

As material know-how evolved and chemical companies explored, developed and gained experience in part manufacturing, design and cost optimization of the acoustic baffle began.2-4Extruded rubber-based chemistries that required labor-intense die-cutting and assembly were augmented with automated injection moldable thermoplastic chemistries, resulting in lower labor costs, higher flexibility and more freedom in design. As the competitive push in the baffle market began and automakers continued the cycle of cost reduction with model changeover, the simple full-layer baffle evolved into a race track baffle (see Figure 1). The full layer of the expanding material was replaced with a perimeter seal of expandable material and a core of thermoplastic.

Since vehicle styling and safety technologies continue to advance, the need for smaller, stronger pillar sections that offer the driver more visibility and increased occupant safety are the norm. Using improved cavity section designs and high-strength steels, as well as relocating sunroof drain tubes into the cavity, will provide the automaker the advantage they anticipate. With the design freedom created by these moldable thermoplastic baffles, they could now be considered in these areas of the vehicle structure that historically were untreated.

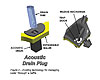

Figure 2. Acoustic Drain and Flap Assembly Baffle

A Unique Solution

Routing a soft, pliable sunroof drain tube through a body pillar section with an expanded cavity sealer in the way presents a formidable challenge. After assembly, the cavity section “seal” needs to be maintained in order to gain the benefit for which the sealer is installed.5To add to the difficulty, not all vehicles get a sunroof drain tube installed, so the specific baffle must perform even if a drain tube is not present. Although assembly processes by the OEMs are rigorously developed, errors in the physical assembly of the vehicle are always possible. If a tube is installed by mistake and needs to be removed, the baffle should maintain its performance.After careful review of existing treatments and solutions, none provided the needs of managing both the installation and removal of the drain tube. They did, however, provide a good basis for benchmarking baffle performance limits where water management treatment is required. These existing treatments, along with a unique solution that meets both needs of tube installation and removal, will be comparison tested against race track design baffles and against each other for acoustic performance.

The race track design baffle, while providing outstanding acoustic performance, does not provide any means for water management. The two existing treatments identified and developed were the acoustic drain and the flap assembly baffle. Figure 2 illustrates these designs in terms of their functionality. The acoustic drain is an insert plug with a series of offset holes that facilitates water drainage while providing a tortuous path for noise.7This plug is robust and can be readily applied in many application areas and parts.

The limitation, however, is that the drain tube carrying the water must terminate above the baffle itself. In this case, water simply drains onto the insert and passes through. Management of water coming out the other end must then be considered. If the tube needs to pass through the section, the second existing treatment methodology would have to be used.

The flap assembly baffle integrates a trap door and release mechanism that is deployed when the tube is installed. If no tube is present, the door remains closed and the baffle is sealed. If a tube is installed, the door is released and the tube passes through with the sealing functionality maintained between the tube outer surface and inner wall of the funnel, optimized by the shape of the funnel to best match the tube. In the case where the tube may need to be removed, the door would remain open and the acoustic benefit compromised.

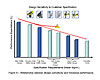

Figure 3. Acoustic Performance Comparison

Race Track Baffle vs. Existing Baffle Designs

Figure 3 compares the noise-blocking performance of the existing solutions for water management to the typical race track baffle design. Sound insertion loss (IL) measured in accordance with SAE J2846 is plotted from 800 to 16,000 Hz. It should be repeated for clarity that the race track baffle design has no provisions for water management, while the design solutions investigated were selected for this very reason. Clearly, the overall performance of the acoustic drain solution remains favorable despite the added complexity in its design. Note that only water can pass through; no accommodations for a drain tube itself are made.In comparing the flap assembly baffle to the acoustic drain baffle design, it is possible to see that, while an acoustic benefit is still shown, the performance has necessarily diminished. The flap assembly design was originally developed to address vehicle platforms with sunroofs and required the drain tube as an optional accessory in the manufacture of a vehicle (i.e., some cars would have a drain tube installed, others would not). Creating more complexity in design and function clearly shows an impact on performance, as demonstrated by the results.

Figure 4. Relative Acoustic Performance of Self-Closing Baffle

A Self-Closing Baffle Design

The new challenge presented in recent customer specifications is to consider the removal of the drain tube if installed in a vehicle that does not require the tube. After many concepts and design iterations, an innovative, spring-mechanized, self-closing trap door funnel baffle was developed. On the open end of the funnel is a trap door connected through two thin membranes that act as hinges. Between the hinges is a specifically shaped plastic strap that allows for the tube to pass through unencumbered, but provides a return force on the door that closes itself if the tube is removed.In conceptual form, it has been tooled and molded, tested for tube installation effort and initially tested against the flap assembly baffle for IL performance. Figure 4 shows the basic workings of this solution, as well as documented relative acoustic performance. Although there is currently a gap in performance between this and the flap assembly, the self-closing baffle solution presents great potential for design refinements that offer performance improvements.

Ongoing design iterations on the self-closing baffle will drive product functionality and performance equivalents associated to the flap assembly design while maintaining current costs. This no-cost added value to the customer is an attractive solution due to ever-increasing demands for improved safety, enhanced styling and advanced technology. Figure 5 illustrates the relationship between the baffle solutions presented as they are designed to accommodate the various degrees of complex requirements imposed on them for water and hardware management.

Figure 5. Design Complexity vs. Functional Performance

What Does the Future Hold?

As the need for enhanced safety features, better styling, and improved technology is placed on OEMs, continual pressure is exerted on the packaging space available for hardware, trim and available space in the auto body structure. Design-flexible materials like baffles and seals are targeted for change. Accommodation for water management is now placed on parts that historically have not been expected to handle them.As resultant flexibility requirements are increased on baffles, the design complexity is increased and the acoustic performance is diminished. The collected data clearly show this relationship between design complexity and performance. Tested design solutions included:

- Typical race track baffle-no water management is required

- Acoustic drain baffle-simple water management is needed, but no drain tube accommodations

- Flap assembly baffle-accommodations are now made for water drain tube installation

- Self-closing baffle-an additional need to be able to remove the water drain tube is imposed

While the component-level test data presented herein still show a slight performance gap to current marketplace solutions, the added challenges of innovative water management techniques managed by the concepts as proposed are illustrated as viable. The self-closing design solution continues to evolve, and design iterations are in process to drive total performance in line with current production solutions.

For more information, contact Sika Corp. at 30800 Stephenson Highway, Madison Heights, MI 48071; phone (248) 577-0020; or visit www.sikausa.com.

References

1. Weber, P. E., Hopton, G. W., “Characterizing the In Vehicle Performance of Expandable Sealants Used As Acoustic Baffles,” SAE Technical Paper 1999-01-1687,1999.2. Chang, R.J., Dawes, K., Schwartz, L. D., “Expandable Foams with Programmed Expansion as Body Cavity Filler,” SAE Technical Paper 980590, 1998.

3. Visintainer, A. P., Saha, P., “Acoustic Study of Cavity Fillers Vehicle Applications,” SAE Technical Paper 971931, 1997.

4. Chang, R.J., Biche, B., Chiotis, A., “Design and Acoustic Performance of Baffles Based on Programmed Heat-activated Foams,” SAE Technical Paper 1999-01-1673, 1999.

5. Saha, P., Myers, R.D., “Importance of Sealants for Interior Noise Control of Automobiles,” SAE Technical Paper 920412, 1992.

6. SAE International Surface Vehicle Recommended Practice, “Laboratory Measurement of the Acoustical Performance of Body Cavity Filler Materials,” SAE Standard J2846, Issued 2010-05.

7. Saha, P., Jones, D., “Acoustical Drain Plugs in Body Cavity Sealer ‘Baffles,’” SAE Technical Paper 971908, 1997.