An optimized LED curing system is essential for process efficiency.

As today’s manufacturers continue to look for ways to be more efficient and improve their processes, light-emitting diode (LED) curing has developed into an increasingly popular topic of discussion. Common questions about the potential impact of LED curing technology include “How can LED curing improve my assembly process?” “Are all LED curing systems created equal?” “What do I need to know about the LED curing system relative to the adhesive?” “How do I select the right LED curing system?”

The Evolution of LED

As a relative newcomer to the light-curable materials (LCM) industry, LED curing lights continue to evolve as an ideal replacement for the mercury arc lamps that have been the industry standard for several decades. LED curing is attracting a great deal of focus in the industry due to benefits such as lower operating costs, longer useful life, cooler curing and “green” attributes. Experts predict LED curing lights will continue to evolve over time and eventually dominate light-curable coating, resin, potting, and assembly applications in industries such as medical, electronics, automotive, aerospace, appliance, and others.

However, this evolution is not without its challenges. As many manufacturers have experienced, simply inserting LED curing into an already existing process is not a guarantee of success. This assumption of interchangeable parts can result in frustrating performance failures that ultimately cost manufacturers time and money.

One often overlooked fact is that it is essential to match the wavelength of the LED curing lamp with the absorption spectrum of the LCM photoinitiator in order to yield the required performance characteristics and ensure a sound investment. This successful pairing is dependent upon having an optimized solution in which a cohesive combination of compatible LCM and LED curing system is established.

The Curing Process

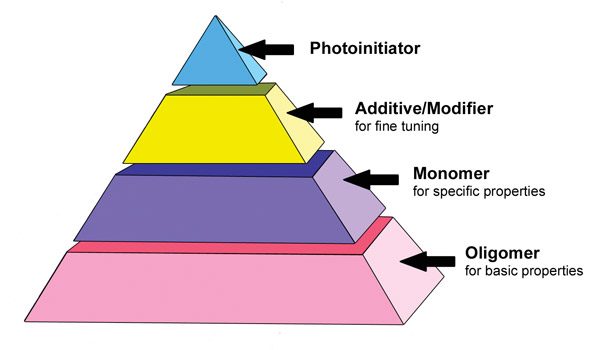

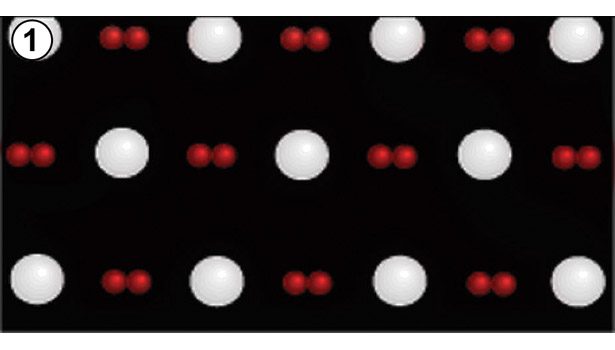

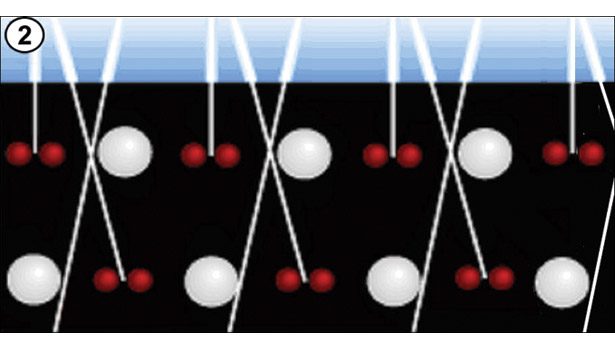

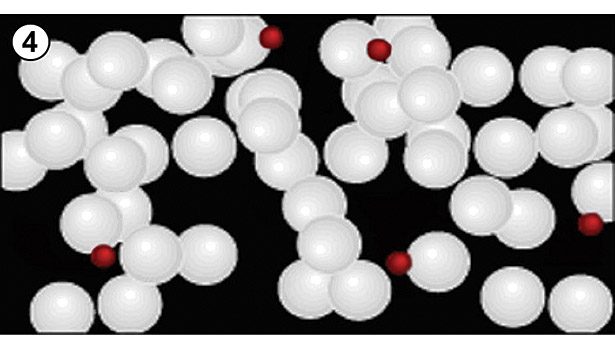

LCMs are typically comprised of five basic elements: the photoinitiator, additive, modifier, monomer and oligomer (see Figure 1). The ultraviolet (UV) light curing process begins when the photoinitiator in the LCM is exposed to a light energy source of the proper spectral output. As illustrated in Figure 2, the molecules of the LCM split into free radicals (initiation), which then commence to form polymer chains with the monomers, oligomers, and other ingredients (propagation), until all of the ingredients have formed a solid polymer (termination). Upon sufficient exposure to light, the liquid LCM is polymerized, or cured.

LED curing offers several advantages over broad-spectrum arc lamp curing, including:

- High electrical efficiency and instant on/off capability for lower operational costs

- Long service life that eliminates bulb replacement and reduces maintenance costs

- Compact equipment that reduces the size and cost of the light curing system

- Cool light radiation that extends curing capabilities for heat-sensitive substrates

- “Green” attributes that eliminate mercury and ozone safety risks, as well as handling costs

- Narrow wavelength spectrum emission that minimizes substrate thermal rise

Selecting a System

In order to implement LED curing technology into any application, it is important to first determine if all aspects of the process are conducive to this approach. Substrate materials, LED-curing-compatible formulations, cure speed requirements, and post-cure bond characteristics are all key to successful results.

Phase 1: Dispense

In selecting a dispense system, the following criteria needs to be established:

- Type of dispense application (e.g., dot, potting, bonding two substrates, coating, bead or sealant)

- Will the adhesive be applied manually or with automation?

- Is this a new or existing dispense system?

- What size and type of container will the adhesive be dispensed from (e/.g., syringe, cartridge, cylinder or pail)?

Phase 2: Adhesive

The following performance characteristics and application conditions need to be identified when selecting the adhesive:

- • LED curable

- Viscosity (flows or thixotropic)

- Durometer (rigid or soft)

- Adhesion properties to the substrates

- Is the substrate UV blocking?

- Cure time meets production requirements

Phase 3: Curing

In selecting the curing equipment, the following questions need to be answered:

- Does the wavelength of the equipment match the adhesive?

- Is a spot lamp, flood lamp or conveyor system necessary?

- Will there be a wand- or cabinet-mounted LED light source?

Modifying an Existing Process

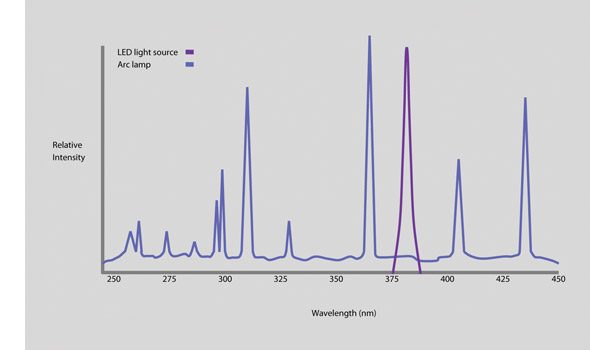

While direct replacement of a broad-spectrum arc lamp with an LED curing light is possible, an evaluation of many other process parameters is essential. An adhesive formulated for an arc lamp might perform poorly when cured with an LED light source. The wavelength distributions emitted by an arc lamp and an LED are quite different (see Figure 3).

Without evaluation and process adjustment, direct replacement of an arc lamp spot curing system with an LED spot curing system can result in substandard bond performance. Replacing an arc lamp with an LED light source could be a simple process, such as modifying the curing parameters of an existing process, or more a complex one, such as changing the adhesive to one properly formulated for the spectral distribution characteristics of the LED light source. It is essential to match the wavelength of the LED curing lamp with the adhesive photoinitiator’s absorption spectrum.

The Right Combination

By offering significant cost savings and efficiencies in adhesive, potting, coating, and assembly applications, LED curing technology will eventually become the industry standard. By itself, however, LED curing is only part of the picture.

A seamless homogenization of the technologies required for a specific application should ensure that the component substrate(s), adhesive, dispense methodology, and curing approaches are all in optimized harmony with one other. A cohesive combination of compatible LCM and LED curing system must be established.

For more information, contact Dymax at 318 Industrial Lane, Torrington, CT 06790; phone (860) 482-1010; email info@dymax.com; or visit www.dymax.com.