EXCLUSIVE PODCAST- Follow this link to hear Alastair Hill, Dow Elastomers’ global marketing manager for Adhesives, discuss hot-melt formulation challenges and the benefits of the new AFFINITY products with Managing Editor Teresa McPherson.

Dow Elastomers will introduce new polymers for hard-to-bond substrates and enhanced formulation flexibility at the World Adhesive & Sealant Conference.

Dow Elastomers, a business unit of The Dow Chemical Co., announced it will debut two new polymers in its AFFINITY™ GA polyolefin elastomers (POEs) line at the World Adhesive & Sealant Conference (WAC), which will take place September 18-21 in Paris. The two new grades, AFFINITY GA 1000R and AFFINITY GA 1875, reportedly were developed as solutions to address the evolving needs of the company’s customers.

“Our customers in the adhesives industry desire enhanced functionality and aesthetics in their applications,” says Alastair Hill, Dow Elastomers’ global marketing manager for Adhesives.” Not only are we seeing a noticeable increase in the use of hard-to-bond substrates in packaging being driven by the desire for improved appearance or for functionality, but formulators also need to provide even more customized solutions that address broad application temperature requirements and viscosity levels. We’re building on the well-known advantages of the family of AFFINITY GA polymers, and with AFFINITY GA 1000R and AFFINITY GA 1875 we can offer customers an enhanced portfolio that addresses these requirements.”

High-Temperature Toughness

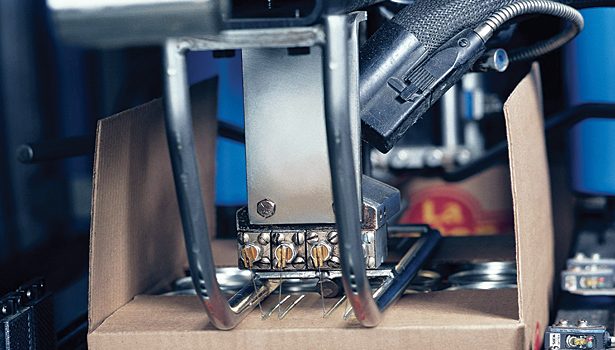

AFFINITY GA 1000R is a maleic anhydride-grafted polymer offering excellent bond strength for hard-to-bond substrates, such as coated papers and boards or containing high quantities of recycled paper, as well as improved heat stress. According to Hill, this helps ensure a package’s contents remain sealed throughout the warehouse or storage and transportation environment.

“Heat stress is the ability for a bond to maintain its seal at higher temperatures, and AFFINITY GA 1000R offers 5-10°C higher heat resistance to ensure the package and the contents stay sealed,” he says. “In addition, it adds a formulation flexibility to give formulators the tools to be able to create adhesives to bond to hard-to-bond substrates.”

Low-Temperature Bonding

AFFINITY GA 1875 is the lowest viscosity Dow Elastomers offers. Hill says the material’s low viscosity makes it suitable for low-application temperature hot-melt adhesives (LATHMA).

“At a lower temperature, the adhesive is still able to be affective in bonding,” he says. “It also gives advanced formulation flexibility and AFFINITY GA 1875-based adhesives bring other benefits such as low or no smoke and odor, clean processing, ease of application, and water-white adhesives.”

According to Hill, the entire range of AFFINITY GA POEs offers excellent bonding at a variety of temperatures and excellent adhesive mileage per pound. Reportedly the first polymers of their kind, the materials were specifically developed for hot-melt adhesive formulations and a range of polymer modification applications.

For more information, visit www.dowelastomers.com or www.stickingtoinnovation.com.