WACKER recently announced it has developed a new dispersion specifically suited for bonding various surfaces in the paper and packaging industry. Vinyl acetate- ethylene copolymer (VAE)-based VINNAPAS® EP 8010 can reportedly bond challenging paper and cardboard surfaces and offers outstanding heat resistance, very high setting speed and ease of machine processing.

ethylene copolymer (VAE)-based VINNAPAS® EP 8010 can reportedly bond challenging paper and cardboard surfaces and offers outstanding heat resistance, very high setting speed and ease of machine processing.

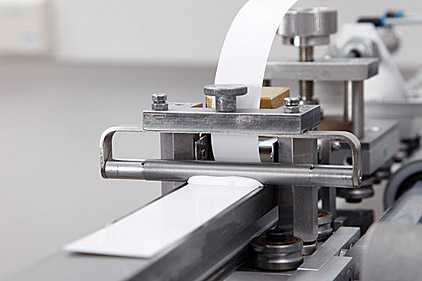

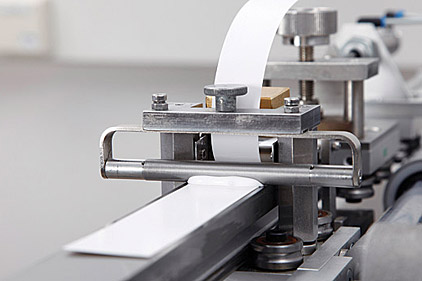

The dispersion is manufactured without the use of alkylphenol ethoxylates (APEOs), and its VAE basis makes supplementary plasticizers unnecessary. VINNAPAS EP 8010 thus can be used for formulating high-performance adhesives for demanding paper and packaging applications in which difficult-to-bond substrates have to be permanently joined, such as printed and coated papers or polymeric film made of polyvinyl chloride (PVC), polyester, or polystyrene. These substrates are particularly challenging to bond because their surfaces are difficult to wet with the adhesive, making it hard to obtain a stable join. In addition to ensuring excellent adhesion to a range of difficult surfaces, this dispersion is also compatible for machine application.

The product shows outstanding setting speed and produces a highly heat-resistant bond. VINNAPAS EP 8010 re-emulsifies fast, thus facilitating cleaning of the application equipment. The polyvinyl-alcohol-stabilized dispersion also scores with its broad formulation scope.

VINNAPAS EP 8010 is characterized by its environmental and user-friendly properties. For example, by allowing the formulation of adhesives without plasticizing additives, it can keep the finished adhesive’s migration potential extremely low. Another advantage is that the dispersion is manufactured without the use of APEO.

The new dispersion, which belongs to the VINNAPAS Plus class for especially demanding product solutions, can be used for formulating adhesives used in high-performance paper and packaging applications, such as food packaging bags and up-market folding boxes for exclusive consumer goods, but also for additional application areas such as laminated products for car interiors.

ABOUT WACKER POLYMERS

WACKER POLYMERS is a leading producer of state-of-the-art binders and polymer additives based on polyvinyl acetate and vinyl acetate copolymers. The materials are used in adhesives, construction chemicals, paints, surface coatings, adhesives and nonwovens, and in fiber composites and polymeric materials based on renewable resources. WACKER POLYMERS has production sites in Germany, China, South Korea and the U.S., as well as a global sales network and technology centers in all major regions.

For more information, visit www.wacker.com.