An increasing number of countries are seeing the advantages of products with low emissions of volatile organic compounds (VOCs) into indoor air. Regulations for reducing product emissions can only be found in Germany and France, but other European countries are expected to establish similar compulsory requirements soon, such as Belgium in 2014. The strongest driving force for low-emission products are markets where programs for sustainable buildings (such as LEED) and ecolabels are continuing to attract more and more users (e.g., EMICODE, GUT, Blue Angel, Indoor Air Comfort, Indoor Advantage).

CURRENT PERSPECTIVES

Historically, Europe and the U.S. have followed different approaches for characterizing low-VOC products, even though the regulations share some common themes. These similarities include the following specifications:

• VOC emissions are characterized by simulating actual use in ventilated test chambers.

• Testing climate is set to 23°C and 50% relative humidity of supply air.

• Tested parameters are VOCs and volatile aldehydes. These are mostly tested by sampling and analyzing test chamber air by adsorption of VOCs on Tenax, thermal desorption, and GC/MS, or absorption of volatile aldehydes with DNPH, solvent desorption, and HPLC.

The regulations differ in several ways as well. The available support for making test specimens of coatings and adhesives varies between the U.S. and Europe. In addition, in the U.S. (and for LEED), most coatings and many adhesives are applied on gypsum or other porous substrates. Because those types of support may show emissions on their own, expensive double testing is necessary (i.e., support before and after application of the coating). Testing reproducibility suffers from the different porosity and adsorptive effects of the materials used as support. In Europe, however, this test is regarded as unreliable and expensive. All coatings are applied on inert surfaces, such as glass or metal sheets. Although this test is different from most use patterns, it is more reproducible.

In the U.S. and for LEED, the ventilation rate during testing is one air change per hour. Emissions are evaluated after 14 days of storage in a ventilated test chamber (or earlier for furniture). In Europe, the ventilation rate during testing is only a half air change per hour. Emissions are evaluated after 28 days of storage in a ventilated test chamber. Often, emissions are also tested after three days (for renovation and early re-occupancy situations).

Any test results need calculation to air concentrations in a reference room or emissions scenario, for comparison with limit values. In the U.S. and for LEED, several different emissions scenarios are used for private offices, open-plan offices, and classrooms. A residential emission scenario is in preparation in California. Essentially, a single product can comply with the specified limit values for one, several, or all of the emissions scenarios. In Europe, this is regarded as too complicated for the market, and only one single European Reference Room is defined as worst-case emissions scenario for all use situations. This is a room of 12 m² surface and 2.5 m height with one window and one door. All products in compliance are rated against this single reference.1,2

In the U.S., most VOC rating schemes limit only 35 individual VOCs taken from the California list of chronic respiratory exposure limit values (CRELs); all other VOCs remain unregulated.3 In Europe, some specifications regulate almost 200 VOCs, while others limit only a short list of VOCs. However, all of them set limits for emissions of total VOCs (TVOC), which also include the VOCs without individual limit values. Today, each country in Europe may set its own limit values for VOC emissions. An initiative that intends to propose Europe-wide harmonized VOC limit values is under development.

NEW DEVELOPMENTS

LEED more or less adapted the U.S. specifications for low-VOC products. In past versions, LEED required product certification by private programs, such as CRI Green Label Plus, FloorScore, ANSI/BIFMA X7.1 and Greenguard. This has since changed, and certification by a specific program is no longer required. Compliance can now be shown by following the testing plan and respecting the limit values of any referenced program.

For coatings, adhesives and sealants, VOC content limits were required instead of VOC emissions limits. VOC content limits have been developed for protecting urban outdoor air against smog formation. VOC content correlates with initial emissions during application, but it does not correlate at all with VOC emissions into indoor air during occupancy. Nevertheless, when LEED requirements for low-emitting interiors were under development, these limits were the only low-VOC program for these products available in the U.S. at the time.

The U.S. Green Building Council plans to fundamentally change its requirements for low-emitting interiors in LEED version 4, which is expected this year. Details were published for a public comment period and may still be subject to changes before LEEDv4 is finalized. Based on recent drafts, the proposed changes will be as follows:

• LEEDv4 will no longer feature specific labels (e.g., CRI Green Label Plus or Greenguard). Instead, LEEDv4 will require compliance with the California CDPH Section 013503 program, which is not a private label but a governmental evaluation scheme.

• A TVOC limit value will not be set, but the TVOC emissions level has to be disclosed to the user.

• LEEDv4 will open an alternative pathway of compliance for LEED projects outside North America. This will be the German AgBB2 evaluation scheme, but it will be supplemented with a low limit value for formaldehyde, as for French A+ class (10 µg/m³ after 28 days).

• Coatings, adhesives and sealants will have to fulfill not only VOC content limits (as before) but also VOC emissions limits. For the VOC content limits, compliance with local law (e.g., European Decopaint Directive, 2004/42/EC) will be accepted as alternative pathway of compliance outside the U.S.

• While the present product-by-product approach still will be accepted, LEEDv4 will supplement this with an alternative evaluation per system (e.g., floor, ceiling, walls, insulation and furniture). A system will be considered compliant if all products in that system comply (e.g., screed, primer, adhesive and carpet in a flooring system).

These changes will allow more products to be included in the evaluation for the LEEDv4 Low-Emitting Interiors credit and encourage the manufacture of more products showing low-VOC emissions into indoor air.

Europe has gone through considerable harmonization of VOC emissions testing and limit values. The German AgBB approach not only serves as the basis for German regulation on limitation of VOC emissions from certain construction products into indoor air, but also is a starting point for an increasing number of voluntary ecolabels. Typically, AgBB is understood as a basic level of requirement, while the voluntary labels are setting a more stringent benchmark for the products on the market with lowest emissions.

The AgBB 2012 approach consists of a limitation of the total VOCs emissions, as well as semi-volatile organic compounds (SVOCs) and limit values for almost 200 individual VOCs. These limit values are called the lowest concentration of interest (LCI) and are derived by dividing an occupational exposure limit for the workplace by safety factors, while taking into account additional toxicological information. A different list of such limit values was published in France4 but never reached regulatory status. Some attempts are being made to harmonize these lists of LCI values across Europe.

French regulations on VOC emissions5 do not exclude high-emitting products from the French market. Instead, labels must indicate the VOC emissions class of that product, based on specifications for TVOC and for 10 individual VOCs, including formaldehyde. In 2014, Belgian regulations will require that VOC emission limits are not exceeded. The limits are similar to the German LCI limit values, though with some minor differences. Belgium intends to refer to harmonized European LCI limits as soon as these are available.

CE marking, which can be attached to a product if it is tested with specified European standards (e.g., for mechanical stability or burning behavior), is required for a number of construction products that are sold in any member state of the EU. This stipulation will soon include VOC emissions for several product groups. Construction products without a CE mark—and thus without emissions level documentation—will then be ineligible for distribution within the EU (if criteria for CE marking are applicable and available for those products).

At present, a horizontal standard for testing VOC emissions is almost finished after withstanding robustness validation.6 The first version of that horizontal standard is expected to be published in mid-2013 as a CEN Technical Specification CEN/TS 16516.1 Different product standards, such as those for floor coverings, will be revised to include VOC emissions. These standards will not redefine the testing method but will refer to the forthcoming horizontal VOC emissions standard or TS; the standard is called “horizontal” because it will be used by a variety of product-specific standards.

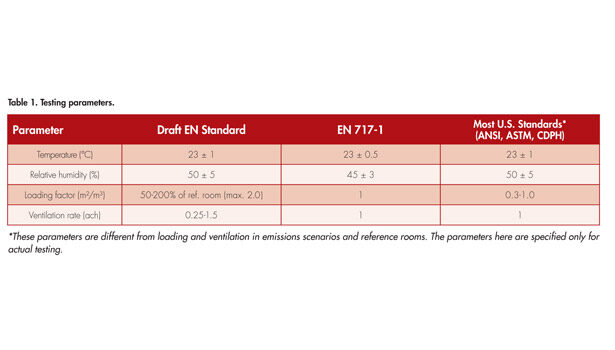

In addition, a standard for coatings is expected as EN 16402 in early 2013. These new testing standards will follow the principles outlined previously. It will specify certain ranges for ventilation and loading factors that will allow running one test only, for reporting in line with several testing protocols: the new EN standard, European formaldehyde testing norm EN 717-1, ANSI and ASTM standards, and CDPH Standard Method (see Table 1). The robustness validation study confirmed that keeping testing parameters within these ranges will not deteriorate the quality of the test result.

The CE marking will not set limit values for VOC emissions into indoor air. Limit values will be defined by each member state of the EU and will never be the same in all countries. The CE marking approach goes for assigning technical classes representing all of the existing national regulatory limit values. As CE marking relies on regulations that specify the required minimum performance in terms of low VOC emissions, voluntary labels will continue setting lower limits for their respective programs. CE marking and expected additional national legal requirements will rapidly increase the number of products with low VOC emissions available on European market.

DISCUSSION

Several regions inside and outside Europe and the U.S. are seeing attempts to establish upper limits for VOC emissions into indoor air from interior products. The number of regulations, voluntary labels and regional LEED specifications in terms of low VOC emissions will increase.

Instead of each country reinventing the wheel, it could be advantageous for new specifications to use the same testing requirements—if not the same limit values—as other regions. This would ease the burden of testing costs for manufacturers. Tested local products would then have a better starting position on the market if exported to the U.S. and to Europe, and products from the U.S. and Europe would be more readily available in other regions (if low VOC emissions are required there).

Low VOC emissions will gain importance in difficult markets. Two main approaches are available for rating VOC emissions into indoor air. While the U.S. targets a small number of individual VOCs, the European approach tries to cover all volatile organic emissions. Differences between test methods will be reduced with a forthcoming European horizontal testing standard for low VOC emissions that will be used for CE marking in the future.

For more information, email voc@eurofins.com.

REFERENCES

1. CEN, 2012a, Document N 189 of CEN/TC 351/WG 2, WI351006, Construction products—Assessment of emissions of regulated dangerous substances from construction products, Paris, AFNOR (publication expected in 2013 as CEN/TS 16516).

2. AgBB, 2012, Ausschuss zur gesundheitlichen Bewertung von Bauprodukten, Evaluation Procedure for VOCs from Building Products, Committee for Health-Related Evaluation of Building Products, Berlin.

3. California Department of Public Health (CDPH), Standard method for the testing and evaluation of volatile organic chemical emissions from indoor sources using environmental chambers, Version 1.1, February 2010.

4. AFSSET, 2009, Avis relatif à une procédure de qualification des émissions de composés organiques volatils par les matériaux de construction et produits de decoration, Paris, AFSSET/ANSES.

5. Decret 2011, Décret no 2011-321 du 23 mars 2011 relatif à l’étiquetage des produits de construction ou de revêtement de mur ou de sol et des peintures et vernis sur leurs émissions de polluants volatils and the Arrêté relatif à l’étiquetage des produits de construction ou de revêtement de mur ou de sol et des peintures et vernis sur leurs émissions de polluants volatils, www.developpement-durable.gouv.fr/Chapitre-II-Industriels-comment.html.

6. CEN, 2012b, Document N 174 of CEN/TC 351/WG 2, Final presentation of test data for Robustness Validation of Methods developed by CEN/TC 351/WG 2; and Document N 173 of CEN/TC 351/WG 2, Robustness Validation of Methods developed by CEN/TC 351/WG 2—presentation and interpretation of the data obtained, and proposals to amend accordingly the draft Technical Specification N 129, Paris, AFNOR (will be published on CEN/TC 351website).