Today’s hot-melt formulators face many challenges, including variations in the availability of raw material supply and the pressure to reduce formulation costs.

| Jump to: |

High-efficiency polymers can help formulators by reducing formulation viscosity or increasing formulation flexibility, which allows for the exchange of resin or oil for polymers.

Altering Viscosity

Lower viscosity formulations provide numerous advantages, such as lower application temperatures. A lower application temperature lengthens pot life, improves operator safety and minimizes warping of heat-sensitive substrates. As a result, thinner and less expensive substrates may be used. Lower viscosity formulations are also easier to spray, which allows for faster line speeds and thinner application lines. Improved formulation flexibility allows the formulator to exchange resin or oil for polymer. This exchange reduces formulated cost and allows the formulator to manage supply variation.

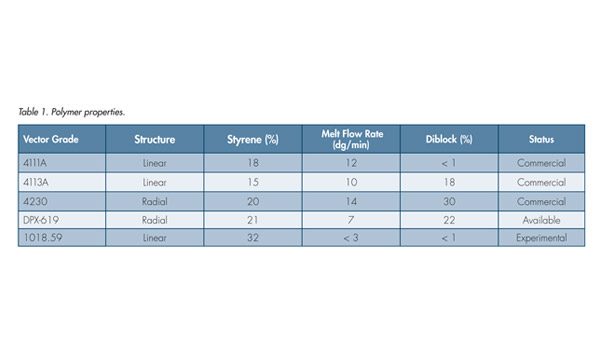

Two approaches can be used to develop high-efficiency styrenic block copolymers. The first approach deals with polymer structure, while the second involves polymer molecular weight. In terms of polymer structure, radial polymers are more efficient than linear polymers in that they can duplicate adhesive performance at a lower viscosity and/or lower polymer loading levels. A high-molecular-weight linear polymer, on the other hand, can be further extended with oil or resin compared to their radial or low-molecular-weight linear counterparts. Both types of polymers can be used in hot-melt pressure-sensitive adhesive (PSA) formulas. The physical properties of the polymers discussed in this article are provided in Table 1.

Formulation Testing

All formulations discussed herein were prepared in solution at 50% solids in toluene and cast as a 1.5 mil film on 2 mil Mylar. The remaining liquor was devolved in vacuo to produce a solid mass. The film samples were tested to stainless steel for shear adhesion failure temperature (SAFT), 180 degree peel, loop and rolling ball tack. The devolved samples were then used to measure melt viscosity. The test methods are listed in Table 2.

Radial Polymers

Radial polymers offer two advantages to the formulator: they produce lower viscosity adhesives, and they can be extended to reduce formulation cost.

Radial polymers offer two advantages to the formulator: they produce lower viscosity adhesives, and they can be extended to reduce formulation cost. |

Developmental polymer DPX 619 is a four-armed, radial, SIS-based polymer. DPX 619 was solution-blended into a typical packaging tape formulation using a midblock resin, LX®-1082, naphthenic oil, Hyprene L500, and Irganox® 1010 as an antioxidant. For comparison, the same formula was made using Vector 4113A, a linear SIS-based polymer. The test results for each formulation are listed in Table 3.

In the same formulation, the radial polymer has a much lower viscosity than the linear polymer. Table 3 shows that Run 2 using DPX 619 has a melt viscosity of 20,800 cP. In comparison, Run 1 using Vector 4113A has a melt viscosity of 75,000 cP at the same temperature. As a direct replacement for the linear polymer, the radial gives a better than threefold reduction in viscosity compared to the standard formulation.

However, radial polymers cannot be used as a mere drop-in for linear polymers. When DPX 619 was replaced 1:1 for Vector 4113, there was a significant drop in peel (1.8 lbs/in. compared to 6.4 lbs/in.). Additional formulating is required to approximate the base formula.

For Run 3, minor adjustments were made to the polymer, resin and oil. The resulting adhesive matches the SAFT of the linear formula and closely approximates the peel value. Moreover, the viscosity is further reduced from 20,800 cP to 15,000 cP at 177°C, a considerable drop from the 75,000 cP of the base formula. Thus, with proper formulation, a radial polymer can be used to produce adhesives with lower melt viscosity than their linear counterparts.

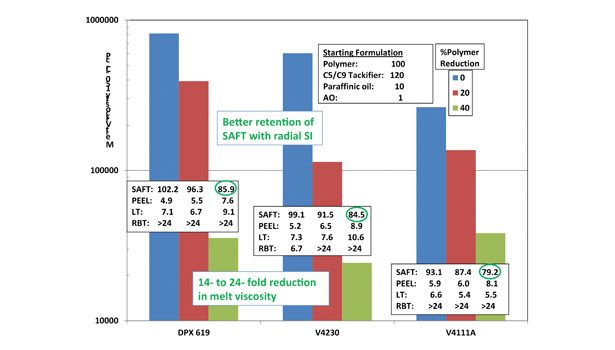

Radial polymers can also be extended and still produce useful hot-melt PSAs. Figure 1 describes the effect a reduction of polymer content has on viscosity, SAFT, 180 peel, loop tack and rolling ball tack. For this data set, the polymer concentration was reduced while the resin-to-oil ratio was maintained. In this case, radial polymers DPX 619 and Vector 4230 are compared to the linear, nearly 100% tri-block polymer, Vector 4111.

For each step reduction in polymer, the radial polymers had a larger relative drop in viscosity than the linear polymer. In addition, the radial polymers had better SAFT retention than the linear polymers. Both radial polymers maintained SAFTs above 80°C, despite a 40% reduction in polymer content.

For all the polymers, peel increased as the polymer content decreased. However, the effect on tack is not quite as clear. For the radial polymers, loop tack increased when the polymer was reduced by 40%, but the response was more flat for the linear polymer. For Vector 4230, rolling ball tack increased as the polymer decreased, but remained unaffected for the DPX 619 and Vector 4111 runs. Nonetheless, the data indicate that radial polymers can be extended to reduce cost or manage raw material supply while maintaining useful adhesive properties.

A formula may also be extended by simply increasing the oil content. In this way, both cost and viscosity are reduced. Figure 2 describes the effect of increasing oil content on viscosity, SAFT, shear, peel, loop tack and rolling ball tack. Generally, the radial polymers (DPX 619 and Vector 4230) show a greater reduction in viscosity than the linear polymers (Vector 4111A and Vector 4113A). In addition, radial polymers maintained better shear values as the amount of oil increased compared to the linear polymers.

In all cases, the peel values decrease as the oil content is increased. Similarly, both loop tack and rolling ball tack decrease as the percent of oil increases. Bear in mind, however, that for rolling ball tack, a decrease is a positive; a shorter rolling distance indicates a tackier adhesive. Comparing the results described in Figures 1 and 2, it is clear that a formulated extension of a radial polymer yields a more functional adhesive rather than mere dilution with oil. Nonetheless, radial polymers can be extended while maintaining useful adhesive properties compared to linear polymers. With minimal reformulation, it is possible to replicate the desired properties of formulations made with linear polymers while achieving a lower overall viscosity. This makes radial polymers a useful material for adhesive formulators.

Linear Polymers

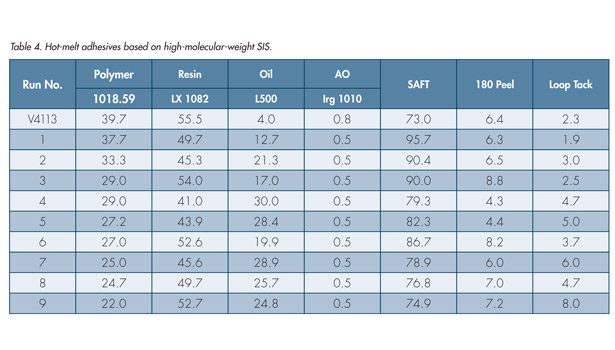

Although a radial structure does have utility, a high-molecular-weight linear polymer can be significantly extended while maintaining properties of the base formula using a lower-molecular-weight linear polymer. Table 4 lists a comparison of Vector 4113 formulated into a basic packaging tape formulation to a variety of formulas using an experimental, high-molecular-weight, SIS polymer (1018.59). The design objectives of each run are to: (1) meet or exceed the SAFT of the Vector 4113 formula, (2) have a peel strength of greater than 3.5 lbs/in., and (3) maintain a loop tack close to that of the base formula. The test results in Table 4 are ranked by polymer concentration.

Runs 1 through 9 show a clear trend of decreasing SAFT with polymer concentration. Run 1 with 37% polymer has a SAFT of 95.7°C, while Run 9 with 22.0% polymer has an SAFT of 74.9°C. Peel and loop tack, however, do not show a clear trend with respect to polymer concentration. This is not a concern; rather, it indicates formulation flexibility.

The data in Table 4 indicate that, using the exact same set of raw materials, all three objectives can be met using a variety of formulations by simply reapportioning the levels of polymer resin and oil. Moreover, Runs 1 through 3 and 6 through 9 either meet or exceed all the properties of the base formulation. This information essentially provides six different ways to meet or exceed the properties of the base formula. Such flexibility helps the formulator balance adhesive performance against raw material supply.

The results in Table 4 indicate that all the formulations meet the requirements using lower concentration of polymer than the base formula using Vector 4113. Moreover, all the formulations use considerably more oil than the base polymer. Thus, Runs 1 through 9 in Table 4 have a lower formulated cost than the base formula.

Flexible and Cost Effective

The benefits of high-efficiency stryenic block copolymers offer many advantages to the hot-melt formulator. Radial polymers produce useful adhesives at a lower viscosity and can be extended to reduce cost. Similarly, using a higher molecular weight polymer can further extend the formulation, allowing for additional flexibility and cost reduction.

For additional information, contact the lead author at (225) 309-0229 or paul.dalley@dexcopolymers.com, or visit www.dexcopolymers.com.

To find suppliers of styrenic block copolymers and other products, visit www.adhesivesmag.com/suppliers.