Adhesive bonding can be used to assemble identical materials or materials of different types; the purpose of such an assembly is to transfer mechanical loads in a given environment. Adhesive bonding is a broadly used assembly technique that is often linked to productivity gains or weight savings. The automotive, building and construction, aerospace, and railway industries commonly use adhesives to reinforce structures in conjunction with standard methods such as welding, riveting and screwing.

Assembly Solutions

The main advantage of a welded or riveted assembly is the handling time and low cost. It can easily be incorporated into automotive mass-production processes or construction applications. In the industrial sector, however, environmental constraints (such as CO2 emission concerns) or performance enhancement requirements are forcing companies to reduce the structural weight of their products. The frequent use of standard steel is giving way to the use of specialty steels (smaller thicknesses) or lower-density materials with the same mechanical strength (greater thicknesses), such as aluminum or composites. Traditional assembly solutions then become less competitive, or even unfeasible.

While these materials have the advantage of being more lightweight, assembling them comes with other constraints, such as thermal expansion differences that create bonding issues. In addition, drilling composites can cause fiber delamination, which could damage the structure over time. Thanks to their properties, adhesives can provide a partial solution to these problems.

Structural adhesives have a number of advantages, especially where the integrity of materials is concerned. Whereas welding and riveting processes are contained within small surfaces and potentially create stress points in the materials that lead to cracks in the structures (and possible permanent degradation of the mechanical and torsional strength), a thin layer of adhesive distributes stresses on the surface more evenly.

To give the assembly the necessary mechanical properties, an adhesive must be strong enough, with a combination of high Young’s modulus and high fatigue and peel strength. Adhesives with high Young’s modulus (> 1,000-3,500 MPa) and high glass-transition temperature (Tg) (> 110°C) are generally used to reinforce steel or aluminum structures.

For example, in the automotive industry, high modulus significantly increases the torsional strength of a chassis. If only an adhesive is used, geometry-related problems can arise due to a decrease in the adhesive’s modulus under heat (> 140°C). If only riveting is used, local stresses can have a permanent effect on the integrity of the materials. This phenomenon occurs especially during cooling of the assembly. Hybrid assembly solutions (riveting/screwing/clinching combined with adhesive bonding) are one way to achieve high production rates. Mechanical assemblies are used in these cases for a variety of reasons, including processing times, the peel strength of assemblies subject to loads, geometry or crashworthiness.

Choosing an Adhesive

Adhesive choices include one- and two-component polyurethanes (PUs); one-component, hot-cure epoxies; two-component epoxies; or methacrylates. High modulus epoxy adhesives are a potential solution, but their use has always been limited by the loss of performance in the presence of high allowances (> 0.5 mm) and by their low peel strength and elongation. Epoxy adhesives are usually very good products, especially for their shear strength. Even though damping products have been added to this type of matrix in recent years, the thermoset structure of this type of adhesive has low elongation properties, so it is less capable of adapting to differential expansion. Their main field of application is on steel structures, limited to allowances of 0.2-0.5 mm.

One- and two-component PU technologies can also be a good solution, as they have low modulus and do not subject the composites to much load at the bonding interfaces. To constitute a robust solution, PU adhesives usually require primers on the substrates (e.g., windscreen bonding). The slow rate of “full” cure can also be an obstacle in a process that requires rapid stressing of assemblies. In general, PU adhesives exhibit high elongation (150-800%). Their average shear strength (<15 MPa) can be an obstacle to achieving the necessary stiffness. Their peel strength can be quite high (> 20 N/mm in T peel test), and this type of matrix can also adapt for high allowances (> 0.5mm).

In addition, the usual methacrylate adhesive technologies are suitable for ambient-temperature bonding, although their field of application is limited by a high Young’s modulus at ambient temperature that drops to very low starting at temperatures of 80°C. One advantage of these adhesives is a rapid handling time with little or no surface preparation required. However, their typically thermoplastic Young’s modulus limits their use to accessory and non-structural parts, and their low Tg (usually 90°C) does not allow the required mechanical strength at high temperatures.

Ideally, an adhesive with high Tg (> 110°C) and low modulus (250-1000 MPa) would appear to be the best solution to make a structure stiff, in combination with traditional solutions like rivets. Because these adhesives have their limits in terms of low modulus (PU) or high Tg (epoxy), rubber and other fillers usually must be added to improve the physico-chemical properties. With these anisotropic adhesives (filler effect, in particular), the adhesive can bear stress only in one load direction (generally shear). In the automotive industry, however, there are multiple load directions, so the hybrid assembly must be capable of adapting to shear, tensile and peel stresses, among others.

Adhesives can suffice by themselves at lower production rates, or when the bonding surfaces enable high mechanical strength. Bonding applications include automotive flooring; road sign stiffeners; or all-composite bonding, even for very long parts (e.g., bonding boat hulls and decks together).

In terms of cycle times and cost, a 100% bonded assembly can lead to significant process and tooling savings. For example, productivity gains of up to 75% are possible on refrigerator truck assembly lines that previously used riveting technology, since drilling operations are eliminated. An adhesive with rapid handling time can lead to even more productivity gains and reliability.

Hybrid Solution

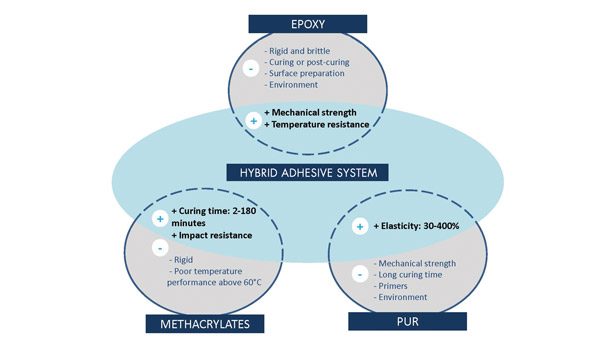

In order to obtain the necessary mechanical strength along with isotropy, the elongation required for adaptation to thermal expansion differences, and industrial compatibility (minimum need for surface preparation, oil tolerance, etc.), researchers have developed hybrid structural adhesives that combine all of these characteristics using three bonding technologies—epoxy, polyurethane and methacrylate.* These hybrid systems provide the durability and mechanical strength of epoxies with the elasticity of a polyurethane and the assembly speed associated with methacrylate. This structural bonding technology combines elongation, low modulus and high mechanical performance with high impact, peel, and shear strength. The isotropic structure allows movement in all load directions. Performance properties include shear strength of 25 MPa and peel strength of up to 25 N/mm.

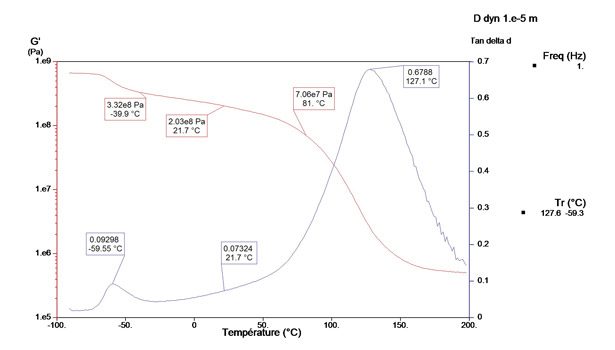

In the case of a hybrid composite/metal assembly, the low modulus does not affect the materials, including when problems of allowances between substrates can create stress points as the temperature rises or drops. The new technology’s high allowances (0.1-9.0 mm) give more flexibility and assembly tolerance. Its low and high Tg ranges from -65°C/110°C to 165°C allow loading of the adhesive in its rubbery state and therefore to obtain very high damping over the entire temperature range.

Multiple Benefits

While traditional assembly technologies are still relevant, they are limited to the assembly of substrates of the same type (excluding composites). A 100% adhesive-bonded assembly is valid when there is enough overlap and the industrial rate of assembly allows it. Load distribution is also an advantage for an adhesive. Weight savings is key; minimizing the use of mechanical assemblies can lower the weight of a vehicle by up to 7 kg, and a lower-density product also allows a significant saving. Multi-material assemblies are developing rapidly, and adhesive technologies appear to be keeping up with the new constraints in terms of process, weight, cost, and hygiene and safety issues.

For additional information, visit www.aderis-specialties.com.