Adhesive nasal strips were first created in the early 20th century not for people but for racing horses. Horse trainers found that their horses raced better with the strips in place. The original nasal strip for human use is credited to Bruce Johnson in 1991. Johnson was looking for a way to remedy his own nasal congestion. After many attempts, he found that an adhesive patch with spring tension applied to the outside of the nose provided good results. Johnson patented his Breathe Right device and, with help of a marketing team, began selling the product in 1992.

Nasal strips’ popularity among consumers took off in 1994 when Johnson and his team sent samples to several National Football League teams. The NFL’s Herschel Walker is credited as the first NFL player to use the strip on national television, along with the San Francisco 49er Jerry Rice.1

Now owned by GlaxoSmithKline, the Breathe Right brand is still a popular consumer health aid. Several competing brands and generic variations are also now available. Consumers use them to relieve congestion due to allergies, colds, or the flu; to alleviate snoring; and to increase air intake during exercise.

Strip Design

The nasal strip has a simple but effective design; most nasal strips on the market are thin, rectangular-shaped patches. The strip is made of a stiff and flexible material with adhesive applied to the underside (the side applied to the nose). When the strip is applied across the top of the nose above the nostrils, its spring tension pulls the nostrils open, making it easier for air to pass through the nose.

Each nasal strip brand offers several variations, including strips for sensitive skin and stronger “Extra” strips for people who find that the original design of the strip doesn’t work for their nose shape or who have trouble applying the original. Consumers have several expectations for these products:

• The product should be adhesive enough that it doesn’t fall off during sleep or exercise

• The product should not cause any redness or rash when removed from the skin, and the removal should cause minimal discomfort

• The product should be easy to use, flexible enough for repositioning and not fold onto itself during application

These expectations can present a challenge to nasal strip manufacturers as they try to balance the right amounts of spring tension vs. adhesion. The spring tension has to be strong enough to open the nostrils, but it cannot be so strong that the adhesive will fail to stick to the skin. Adding to the challenge is the unknown condition of the substrate (skin) that the adhesive is applied to. From oily to sweaty to freshly showered skin, the product may encounter a variety of diverse conditions. Manufacturers tend toward applying more adhesion to address as many of these conditions as possible. However, too much adhesion can damage the thin, delicate skin of the nose when the strip is removed. The right amount of adhesion is essential to the product’s success on many levels.

Comparing Adhesive Properties

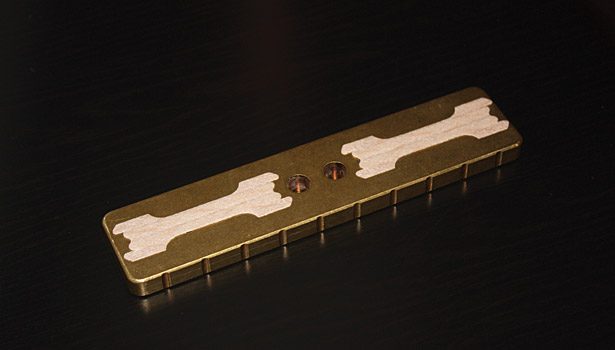

A typical adhesive test is performed using a texture analyzer fitted with a probe. The probe is programmed to make contact with the adhesive and then apply a chosen force consistently for a specified duration to establish an adhesive bond. Once the time duration is met, the probe pulls away from the adhesive at a specified speed, which then breaks the adhesive bond. Figure 1 shows the placement of a nasal strip on the underside of the indexable testing plate. A recent study on transdermal patch testing, such as nasal strip testing, suggests “that for quality control purposes, stainless steel is the most discriminatory substrate for peel adhesion evaluation.”2

Three different nasal strip brands were selected to test using the original and Extra varieties of each brand. Designed for noses that need extra help opening nasal passages, the Extra variations include an extra-springy band and are often up to 50% stronger than the original version of the product. For testing purposes, the brands will be referred to as Brand A, Brand A Extra, Brand B, Brand B Extra, Brand C, and Brand C Extra.

Each of the products was purchased locally. Using a TA.XTPlus texture analyzer from Stable Micro Systems fitted with a TA-303 indexable tack fixture and a TA-57R stainless steel probe, adhesion tests were conducted on each of the products. The rounded probe was selected because it generates results that are significantly less variable than results using a flat-ended probe.

Ten replicate tests were conducted for each product. The test data yielded measurements for four adhesive characteristics: tack, total area of work, stringiness and an adhesive ratio. Table 1 shows the average data for these four adhesive characteristics for each product tested.

Tack

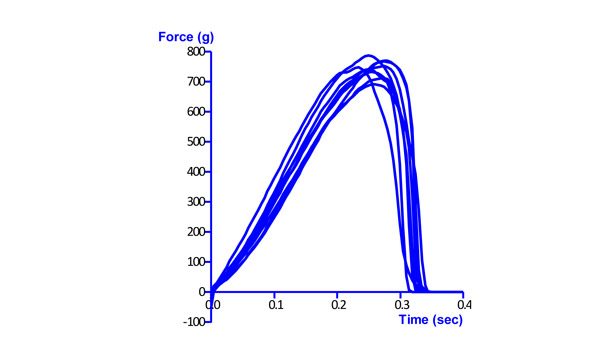

The tack measurement is determined by measuring the peak force that the adhesive applies to the probe as the probe pulls away. A force of 1,000 g was held on the adhesive for 15 sec in order to create the bond and then break it. For all of the products, the Extra variation of each brand had considerable more tack than its original variation (see Figure 2). Considering that the Extra variations are marketed to consumers who have trouble applying the strips for a variety of reasons, a little extra tack will help the strips adhere more strongly.

Brand A and Brand A Extra had the lowest tack measurements of all six products. Brands B and C with their Extra variations had no statistical difference compared to each other. However, all Brand B and C products measured significantly more tack than Brand A.

Area of Work

The total area of work represents the total amount of energy exerted as the probe pulls away from the adhesive layer. Again, the Extra variations of each brand measured higher work than their original variation. Brand A and Brand A Extra required the smallest areas of work. Brand B and Brand B Extra required more than double the area of work compared to Brand A, suggesting a product that is harder for consumers to remove and one that may cause redness and swelling. Brand C and Brand C Extra measured in the middle. Figure 3 displays the repeatability found with the TA-303 indexable tack fixture and a TA-57R stainless steel probe.

Stringiness

Stringiness is the distance that an adhesive stays in contact with the probe as it pulls away from the sample. In this measurement, the brands differed widely not just among each other, but also between their original and Extra variations. For both Brands B and C, the original variation was stringier than the Extra variation. However, for Brand A, it was the Extra variation that proved to be stringier than the original.

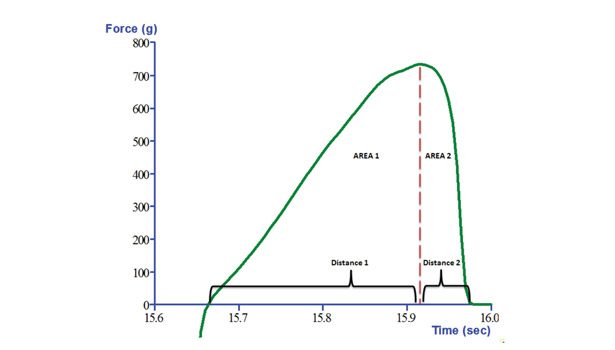

Calculating an Adhesive Ratio

The adhesive ratio helps describe the way an adhesive releases its bonds (see Figure 4). It is calculated either by dividing the pre-peak distance of travel by the post-peak distance or by dividing pre-peak area of work by post-peak area of work. Either method will yield similar numbers. The lower the ratio, the more cohesive the sample is to itself relative to its adhesion to the probe or base. Higher ratios indicate that the sample is more adhesive to itself than cohesive and will potentially leave residue on both the probe and the base.

Brands B and C with their Extra variations yielded similar ratios. However, Brand A and its Extra variation yielded significantly higher ratios at 0.414 and 0.584, respectively. Using the adhesive ratio, it is evident that Brand A and Brand A Extra are less cohesive than Brands B and C.

A Broad Perspective

Adhesives manufacturers relying on a single tack test may be missing important data that helps reveal several adhesive qualities of their products and, by extension, the consumer’s experience. While tack is an important measurement, it is also useful to measure in other ways how adhesive bonds hold and fail. When a consumer evaluates a nasal strip product, the perceived adhesion of a product may be just as important as the actual tack measurement.

While Brand A and its Extra variation have the lowest tack measurements and are the easiest to peel off, their internal makeup results in a larger chance for cohesive failure when compared to Brands B and C, possibly leaving adhesive residue on the consumer’s skin. Brands B and C and their Extra variations have strong tack but will be harder for consumers to remove, potentially causing damage to sensitive skin on the nose along with redness and adhesive burn.

Creating a “perfect” product that addresses all common complaints is a challenge, but by including additional measurements of a product’s adhesive qualities using texture analysis, manufacturers can obtain a more comprehensive picture of their products. This method of testing is calibratable, configurable and very precise in measuring adhesive qualities. No matter the product, this method can yield infinitely useful data for new product development, new formulations and quality assurance testing.

For additional information, visit www.texturetechnologies.com.

References

1. Millman, Nancy, “Success Doesn’t Let Firm Breathe Easy: Even With Sales Of $85.8 Million Last Year, CNS Works To Win More Brand Awareness For Breathe Right Nasal Strips,” Chicago Tribune, January 30, 1997.

2. Wokovich, Anna M., Brown, Stanley A., Shen, Meiyu, Doub, William H., Cai, Bing, Sadrieh, Nakissa, Chen, Mei Ling, Machado, Stella and Buhse, Lucinda F., Food and Drug Administration-Center for Drug Evaluation and Research,Journal of Biomedical Materials Research: Part B - Applied Biomaterials.