Primary and secondary structures that comprise modern aircraft are typically combinations of metals and lightweight carbon fiber- or glass fiber-reinforced polymer composites joined using high-performance adhesives. Historically, the adhesive bonding process required joined substrates to be cured in an autoclave to minimize voids and ensure reliable, high-quality parts. This procedure was time consuming as well as capital intensive. Aircraft OEMs are now seeking more cost-effective technologies, such as out-of-autoclave (OOA) curing that can produce parts more inexpensively than those fabricated via conventional autoclave processing.

In response to this trend, a new structural paste has been developed—designated Epibond® 100-A/B epoxy adhesive—that is formulated for OOA curing. The toughened epoxy exhibits outstanding mechanical properties at temperatures from sub-ambient to 149°C (300°F) and retains its high glass-transition temperature (Tg) values even after long-term exposure to hot/wet conditions. The advanced material also accommodates the needs of aircraft OEM and repair facilities for adhesives that can be stored at room temperature, are easy handle and apply, and oven cure in 1-5 hours. As a result, the new OOA paste adhesive can decrease labor time and production costs.

Aircraft Adhesive Chemistries

Most film and paste adhesives used for aircraft applications are based on epoxy chemistries. Epoxy resins are characterized by outstanding adhesion to a broad range of substrates, high chemical and corrosion resistance, good mechanical and thermal characteristics, low shrinkage upon cure, relatively low moisture absorption, good electrical insulation properties, and the ability to be processed under a variety of conditions.1

Resins

Included in the family of epoxy materials are aliphatic, cycloaliphatic and aromatic epoxy resins, determined by their different backbone structures. The most important epoxy resins are aromatic bisphenol-A-based systems, which are prepared from bisphenol A and epichlorohydrin to produce diglycidyl ether of bisphenol A (DGEBA). Applications for DGEBA epoxies include adhesives, castings and coatings. The materials are also used for laminating, filament winding and tooling.

Other multifunctional epoxy resins include epoxy novolac resins, epoxy cresol and aromatic glycidyl amine resins. The high functionality of epoxy phenol novolac and cresol novolac resins increases their crosslink density, producing the high thermal stability and chemical resistance required for high-temperature adhesives. Commercial aromatic glycidyl amine resins, such as triglycidyl-p-amino phenol and tetraglycidyl-4,4’-diaminodiphenylmethane (TGDDM), demonstrate excellent high-temperature performance. Other resins containing a dicyclopentadiene backbone feature low moisture absorption for better retention of properties under moist and elevated temperature conditions.

Hardeners

In general, epoxy resins are used in combination with catalytic curing agents or other curing agents, such as aliphatic amines, cycloaliphatic amines, aromatic amines, or anhydrides. Catalytic curing agents can be Lewis bases or Lewis acids, which initiate ring-opening homopolymerization. Catalytically cured epoxy resins are ideal for formulating high-temperature-resistant adhesives, prepregs, electrical encapsulants and powder coatings, but the epoxy systems tend to be brittle and moisture sensitive.

Aliphatic amines are relatively moisture insensitive, cure very quickly at ambient temperature and are low-cost hardeners. Disadvantages include a short pot life and relatively high vapor pressure. These curing agents are also moderately toxic and have limited high-temperature performance above 100°C (212°F).

Cycloaliphatic amines have a long pot life; a more favorable ecology, health and safety (EH&S) profile; good adhesion; and very good chemical resistance. They also exhibit good electrical, mechanical and thermal properties with high Tg temperatures. Among the disadvantages of cycloaliphatic amines are their slow reactivity at ambient temperatures and high costs.

Aromatic amines offer excellent elevated temperature performance above 150°C (302°F), good chemical resistance, long pot life and relatively low moisture absorption. The curing agents have long cure cycles at elevated temperatures and usually have negative EH&S profiles.

Anhydrides cure with low exotherm, have good thermal (high Tg), mechanical and electrical properties, low shrinkage and long pot life. However, they require long cure cycles at high temperatures (200°C/392°F) and usually have a less favorable EH&S profile.

Toughening

Cured epoxy resins for structural adhesive applications are usually brittle and notch-sensitive due to their high crosslinked density. As a result, the systems are often toughened by incorporating liquid rubber, engineering thermoplastics, reactive diluents or inorganic and preformed particles into the formulations.

Reactive liquid rubber copolymers such as butadiene-acrylonitrile with various functional end groups, such as carboxyl-terminated groups (CTBN), amine-terminated groups (ATBN), hydroxyl-terminated groups (HTBN) or epoxy-terminated groups (ETBN), are normally used for this purpose. As they cure, the soluble, reactive liquid rubber particles in the epoxy resins precipitate out as a second phase. This phase separation increases the fracture toughness of the cured epoxy matrix. The resulting toughening produces a significant increase in shear strength and peel strength. However, slight decreases in Tg, Young’s modulus, yield strength and oxidation stability are often realized.2

Thermoplastics, such as polyethersulfone (PES), polyetherimides (PEI), polyetherketone (PEK), polyaryletherketones (PAEK), amine-terminated polysulfone (PSF), and hydroxyl-terminated PSF, are also used for toughening epoxy matrix systems. These modifiers are incorporated into epoxy resins because they are inherently tough, ductile, chemically and thermally stable, and have high Tg and high-temperature performance capabilities. The major drawbacks of engineering thermoplastics for toughening are their lack of compatibility with epoxy resins, processing difficulties and sometimes poor interfacial adhesion.

Epoxy resins are also toughened with reactive diluent modifiers. These modifiers produce a chemical reaction that makes the epoxy resin network more flexible. Typical compounds for epoxy toughening include diglycidyl ether of 1,4-butanediol, bisphenol-A, linear aliphatic diols, or oligomers with flexible backbones, such as polythiol, polyol, urethane, hydroxylmethyl groups, or glycidyl-terminated polyurethane.

Another approach to toughening epoxy resins is the incorporation of inorganic particulate fillers, such as glass beads, alumina trihydrate, silica, or pre-formed particles such as thermoplastic powders. Among these powders are triblock of polystyrene, polybutadiene, polymethylmethacrylate (SBM) or core-shell polymers made from latexes with different particle sizes and maximum volume fraction.

In order to produce an epoxy paste adhesive that cures in an oven and retains high Tg after exposure to hot/wet conditions, Huntsman chemists evaluated a full range of resins and hardeners. The new Epibond 100-A/B paste adhesive that is the result of their research combines epoxy resins and amine hardeners with a combination of tougheners and rheology modifiers to maximize mechanical properties, including Tg.

All raw materials used in the composition of the new paste adhesive are commercially available; do not contain any substance of very high concerns as defined under Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH); and listed on the Toxic Substances Control Act registration (TSCA) inventory.3 The resin and hardener parts have been produced at Huntsman’s manufacturing facility.

Adhesive Handling and Processing

Epibond 100-A/B paste adhesive is easy to store and handle. It is stable at room temperature with a 12-month shelf life. As a result, costly freezer storage and time-consuming material thawing are eliminated. The resin-to-hardener mix ratio is 100:44 by weight or 2:1 by volume. The adhesive is hand-mixable or can be dispensed from 50-200 ml dual-barrel cartridges equipped with an 18-element spiral static mixer that minimizes air entrapment for optimal system performance. The paste can be applied using a spatula onto clean substrates and is thixotropic for easy application of thick (up to 0.12 in.) films to vertical surfaces. The system is also formulated using spacer beads to promote uniform bondline thickness.

Epibond 100-A/B paste adhesive has a working time of more than 100 min at room temperature to accommodate use on large projects. To ensure optimum performance, components to be bonded should be assembled and clamped as soon as the adhesive has been applied, providing even contact pressure throughout the joint area during cure. The cure schedule of the new paste adhesive is one hour at 65°C (150°F), plus 3-5 hours at 93-135°C (200-275°F).

Testing demonstrates that parts bonded using Epibond 100-A/B epoxy paste adhesive can be handled after 1.5 hours at temperatures ranging from 49-60°C (120-140°F) or 1 hour at 150°F (66°C) (see Figure 1). Note: A moderate temperature increase produces a significant increase in handling strength to accommodate secondary fabricating and assembly processes on bonded parts before the final oven cure.

Testing Conditions

Lap shear specimens were prepared using 0.160-cm (0.063-in.)-thick Al 2024-T3 clad five-finger coupons with 2.5 cm (1 in.) width x 12.5 cm (5 in.) length that were degreased and treated with phosphoric acid anodizing (PAA) in accordance with ASTM D3933, followed by priming with BR127. Once applied, the primer was dried at ambient temperature for 30 minutes and cured in a 121°C (250°F) preheated air-circulating oven for 30 minutes, yielding a dry nominal thickness of

5 micrometers (0.0002 in.).

The primed Al panels were cleaned with isopropyl alcohol (IPA), dried with lint-free towels and blown with dry nitrogen. The mixed adhesive was then applied on substrate surfaces, assembled, and clamped before moving to the air-circulated cure oven. The cure oven was set at 65°C (149°F) for 1 hour at a rate of 8°C per minute for initial cure/handling, plus 93°C (199°F) for 3-5 hours at a rate of 6°C per minute. All cured specimens were tested per ASTM D1002 at ambient temperature and at other temperatures: -55°C (-67°F), 82°C (180°F), 93°C (200°F), and 121°C (250°F).

Lap shear specimens with the CFRP composite were prepared from 0.318-cm (0.125-in.)-thick panels of 10-ply CFRP composite (T300 3K twill weave made by RTM process with a 177°C/350°F curing epoxy resin). Composite panels were carefully cut perpendicular into five 2.5-cm (1-in.)-wide x 12.5 cm (5 in.)-long specimens and abraded uniformly in one direction with 180-grit sandpaper.

Specimens were cleaned with IPA, dried with a lint-free towel, and blown with dry nitrogen before the mixed adhesive was applied on the substrate surfaces, assembled, and clamped before moving to the air circulated cure oven. The cure oven was set at 65°C (149°F) for 1 hour at a rate of 8°C per minute for initial cure/handling, plus 93°C (199°F) for 5 hours at a rate of 6°C per minute. All cured specimens were tested per ASTM D1002 at ambient temperature. Cured glass reinforced epoxy composite (GFRP) samples used for lap shear were provided externally.

T-peel specimens were prepared by using 0.05-cm (0.020-in.)-thick 30-cm (12-in.) x 30-cm Al 2024-T3 that were degreased and treated with PAA in accordance with ASTM D3933 followed by priming with BR127. Once applied, the primer was dried at ambient temperature for 30 minutes and cured in a 121°C (250°F) preheated air-circulating oven for 30 minutes, yielding a dry nominal thickness of 5 micrometer (0.0002 in.). The primed Al panels were quickly cleaned with isopropyl alcohol (IPA), dried with lint-free towels and blown with dry nitrogen.

The mixed adhesive was applied on the cleaned and dried substrate surfaces with a small amount of 0.025 cm (0.010 in.) glass spacer beads applied along the edge and center of one side of the panel. Panels were assembled, pressurized at 0.3 kg/cm2 (4.6 lbs/in.2), and clamped before moving to the air circulated cure oven. The cure oven was set at 65°C (149°F) for 1 hour at a rate of 8°C per minute for initial cure/handling, followed at 93°C (199°F) for 5 hours at a rate of 6°C per minute. The cured panel was carefully cut into 2.5-cm (1-in.)-wide by 30-cm (12-in.)-long for T-peel testing per ASTM D1867 at ambient temperature.

DMA specimens were prepared by making a casting with 3 mm (0.12-in.) thickness x 65 mm (2.6 in.) width x 65 mm (2.6 in.) length. The casting was cured at 65°C (149°F) for 1 hour, plus 93°C (199°F) for 5 hours. After cure, the casting was carefully cut with a diamond blade with dimensions of 3 mm (0.12 in.) x 13 mm (0.52 in.) x 56-mm (2.24 in.). DMA specimens were then tested with a Q800 System from TA Instruments at 5°C per minute to 200°C per ASTM D7028. The Tg was analyzed at onset storage modulus on the Log scale.

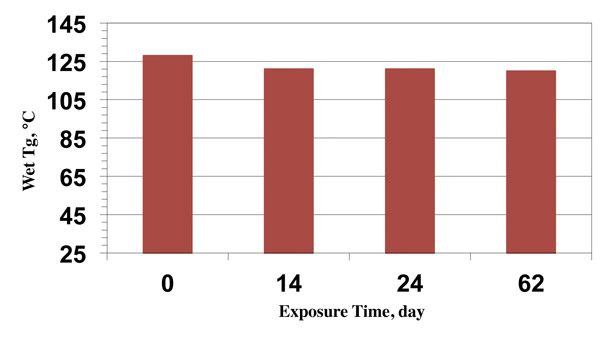

Viscosity of the resin and hardener of the new paste adhesive show that both components are thixotropic pastes. This indicates their mix also behaves as a thixotropic paste affected by shear rates. This is highly desirable feature to ensure a good pumpability and a good wetting of the substrate while maintaining good sag resistance properties. Mechanical properties of the toughened new paste adhesive neat resin are listed in Table 1.

Adhesive Performance

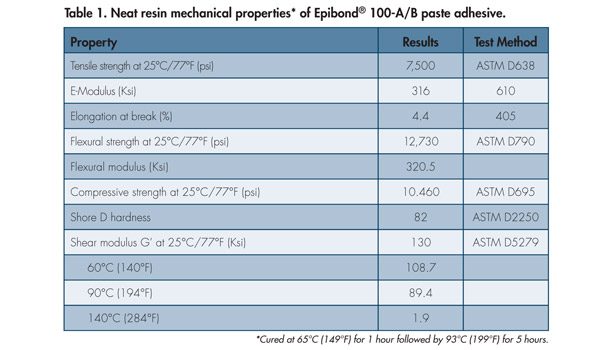

The room- and elevated-temperature lap shear strength of oven-cured Epibond 100-A/B paste adhesive compares very favorably to that of four autoclave-cured film adhesives (FA-1 to FA-4) and two oven-cured paste adhesives (PA-1, PA-2), as shown in Table 2. (Data was obtained from published literature.)

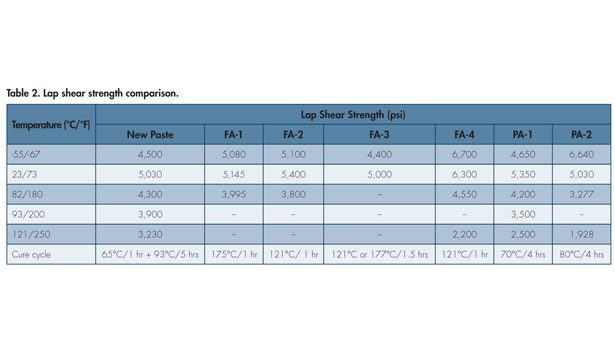

Lap shear tests shown in Table 2 were conducted on aluminum samples. In addition, Huntsman’s new paste adhesive demonstrates high lap shear strength at ambient temperatures on both pre-cured epoxy/carbon fiber-reinforced polymer (CFRP) laminate samples and pre-cured epoxy/glass fiber-reinforced polymer (GFRP) laminate samples (as seen in Table 3).

After environmental exposure of 62 days at 63°C (145°F)/85% RH, no reduction of lap shear performance was observed for the new paste adhesive at room temperature, which is comparable to other autoclave-cured film adhesives and better than paste adhesives. At elevated temperatures of 121°C (250°F), Epibond 100-A/B paste adhesive retained 53% of its strength, which is unique compared with other adhesives currently on the market. The new paste adhesive exhibits a room-temperature T-peel strength similar to that of other film and paste adhesives, with values of 22 pli on aluminum and 20 pli on composite substrates.

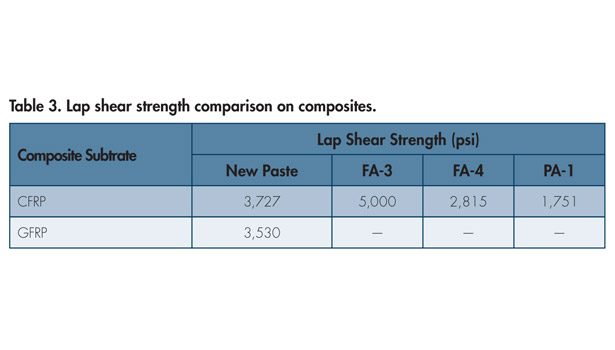

The dry Tg of the new oven-curable paste adhesive is 128°C (262°F) after an initial cure for 1 hour at 65°C (150°F), plus a 5-hour post cure at 93°C (200°F). The wet Tg of cured samples after exposure for 14, 24 and 62 days at 63°C (145°F)/85% RH demonstrate the unique properties of the new paste adhesive. As shown in Figure 2, Epibond 100-A/B paste adhesive retains 94% of its Tg performance after 62 days of hot/wet exposure. This unusually high Tg retention can be correlated with the system’s low moisture absorption. After 24 days at 63°C (145°F)/85% RH, the paste adhesive was saturated with 2.3% moisture absorption.

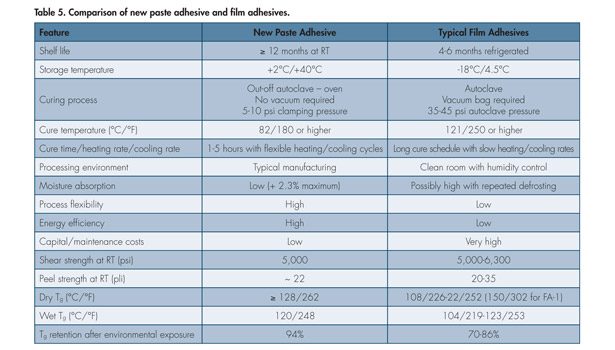

Table 4 demonstrates that, when compared with other film and paste adhesives, the new OOA cure paste retains the highest Tg performance. Epibond 100-A/B paste adhesive can withstand chemical exposure with very low weight gain after 24-hour immersion in a variety of aviation fluids, including gas and oils. The high strength and Tg performance of Huntsman’s new paste adhesive make it an ideal choice for out-of-autoclave bonding applications compared with aircraft film adhesives (see Table 5).

Conclusion

The new out-of-autoclave structural epoxy adhesive meets the requirements for high lap shear strength at sub-ambient temperature, room temperature, and high temperature. Epibond 100-A/B paste adhesive features moderate toughness and high hot/wet Tg retention after long exposure to adverse environmental conditions. The new product is a feasible alternative to already qualified high-performance film and paste adhesives, making it ideal for use in bonding primary and secondary aircraft structures.

For additional information, visit www.huntsman.com.

References

1. “Literature Review of Epoxy Toughening,” Chapter 8, http://Scholar.lib.Vt.edu/theses/available/etd-32398-61326/unrestricted/8-9.pdf.

2. Elwell, M. and Dubouloz, F., “Fundamental of Toughness II,” Huntsman Advanced Materials R&T Learning Programs, The Woodlands, May 18, 2009.

3. “Candidate List of Substances of Very High Concern for Authorization,” December 19, 2012, http://echa.europa.eu/candidate-list-table.