For many people, the glue sticks and glue guns they buy at their local hobby or hardware store are an introduction to hot-melt adhesives—but these products are only a small glimpse of what is possible in the world of hot melts. “Hot melt” does not describe a single, specific adhesive, but rather a variety of different adhesives that are all melted and applied with heat.

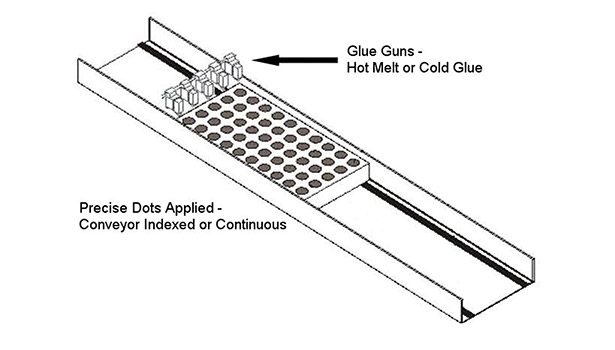

Everyone—from a one-person assembly shop to major corporations—can use hot-melt adhesives. Hot-melt setups can vary from an individual applying adhesive with a basic hand-held glue gun costing less than $160, to high-speed automatic machinery costing hundreds of thousands of dollars capable of applying hot melt to thousands of pieces per hour (see Figure 1). A huge range of options exist when it comes to the available types of hot-melt adhesives, as well as equipment and application protocols.

Hot Melt Usage

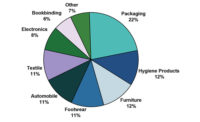

When you think of hot-melt adhesives, your mind may naturally jump to their use in packaging. Cartons, corrugated cases, protective packaging, and other packaging applications rely heavily on hot melts to keep things together and contained. The reality is that hot melts are used in all types of assembly processes—from credit cards, clothing, cabinetry, carpet and cars to shoes, stamps, carpet, windows, golf clubs, picture frames and much more. Hot melts have an endless number of applications.

It is important to make the right choice for your application because hot-melt adhesives are typically not a “one-size-fits-all” product. Ensuring that a hot melt will effectively bond your materials is a major consideration—but not the only one. It is also helpful to explore all aspects of the product, including softening point, open time and other characteristics, to find the hot melt that is ideal for your specific application.

Choosing a hot melt based on sticking power alone can be risky. One company recently had to throw out many of its high-end direct mail pieces because the hot melt that was used to temporarily bond a credit card-type material to a brochure had, over an extended period of time, begun staining the brochure. The company eventually selected a fugitive, removable hot melt that would not stain when applied with the correct temperature, quantity and method. The company’s high-end pieces now have a much longer shelf life, thanks to the selection of the correct hot-melt adhesive and the appropriate application parameters.

Suitable Applications

A hot-melt adhesive is typically a good choice when you’re trying to quickly create a strong bond between two materials, and where the glue bond is stronger than the substrates. That’s what makes hot melts such a good fit for packaging; they are highly effective at creating a strong bond for cartons and corrugated cases. In general, hot-melt adhesives are ideal in situations involving porous or fibrous materials, including paper, cardboard, foams, batting, fiber/fabric, untreated wood and nonwovens.

Hot melts are the ideal adhesive in many situations, but some situations may require alternatives:

• Dissimilar substrates. If you’re trying to adhere two very different materials, like PVC to metal or masonry to wood, you’ll likely need to explore solutions other than traditional hot-melt adhesives. Hot melts don’t work well in joining materials that are radically different from one another.

• Wide temperature variances. The majority of hot-melt adhesives are created to withstand average temperatures from about 32-150°F. Too-low temperatures may cause them to become brittle and fragile; overly high temperatures can make them extremely soft with diminished bond strength. If your end product will experience temperature extremes, you should pay close attention to the advised temperature range for the particular adhesive solution.

• Exterior uses. Most hot melts are not exterior grade. They simply aren’t formulated to stand up to changing seasons and harsh elements. This is one reason why people do not try to glue on their gutters or adhere their mailbox to the mailbox stand using a hot melt.

Making an Informed Decision

When exploring the right hot melt for your particular needs, one of the most important things you can do is get an informed opinion. As you search for the best adhesive, pay close attention to the number of quality questions asked by the vendor. A vendor who truly understands your gluing requirements, your materials and your product is more likely to determine the ideal hot-melt solution for your application than one who hears your first two sentences and starts suggesting products. This sort of verification and demonstration process may take a bit longer, but it should ultimately help you make the best adhesive decision for your end products.

For additional information, visit www.gluemachinery.com.