Competitive snowmobilers, snocross racers, and XGames athletes usePolaris Industries Inc. snowmobiles to help them dominate in extreme events such as racing, long-distance jumping, and freestyle competitions that involve dangerous backflips and extensions. The sleds are designed for terrain domination, enduring the punishment of full-out driving maneuvers, high loads and even crashes. The engineers who build the machines must be sure that the sleds will function reliably under severe conditions and hold tight under stress and at high temperatures.

To ensure that Polaris snowmobiles endure wide temperature fluctuations, hard landings, vibration, and extreme impacts while continuing to perform reliably, engineers trust Loctite anaerobic adhesives (specifically threadlockers and retaining compounds) to ensure the safety of the sleds and eliminate any risk of assembly failure. Threadlockers are used on all threaded fasteners throughout the machine, eliminating the possibility of vibrational loosening. At critical interfaces such as engine mounts, these adhesives permanently secure the threaded fasteners that attach the engine to the chassis. Failure here could mean disaster.

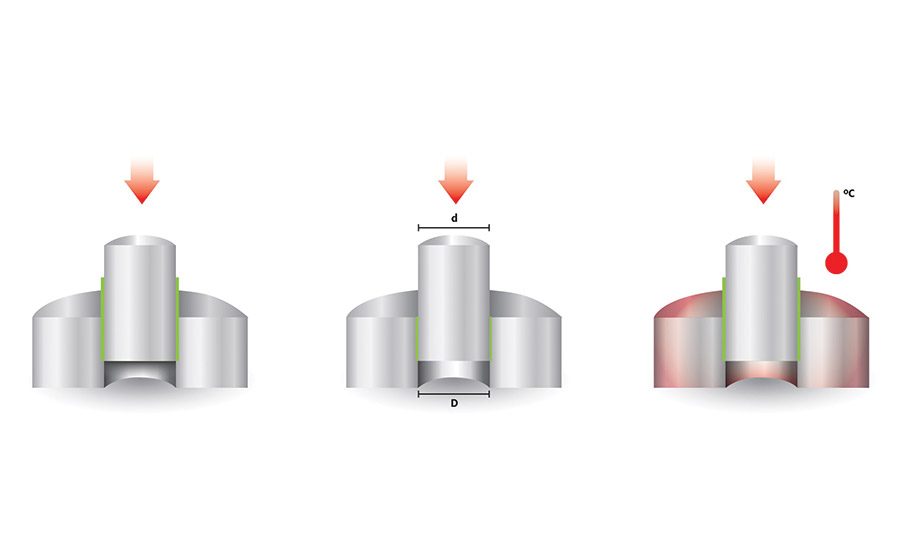

The interference fits found throughout the machine are also of importance. Interference fits join cylindrical parts—such as shafts, bearings, or bushings—to smaller gears or housings, and rely upon extremely high friction to lock parts together so that even large amounts of torque cannot separate the bond. To achieve maximum joint strength and optimal performance, these joints must be highly precise. The inner part of the interference fit is machined to be imperceptibly bigger than the mating hole of the outer part. The larger component is then forced into the smaller part; both deform slightly to fit together, and the two parts unitize and operate as one.

But failure can occur even when the appropriate allowances for interference fitted parts have been painstakingly calculated to achieve maximum friction. In order to calculate and achieve such exacting levels of dimensional precision, both the cost and the time required for component production increase dramatically.

Retaining compounds enable engineers to design robust, lightweight interference fitted joints at a lower cost and in less time than traditional interference fits by reducing the required dimensional precision. They provide strength and reliability and are increasingly being used in general industry to secure interference fitted parts.

Ancillary benefits of retaining compounds include their ability to increase the number of viable substrate materials for an application and their ability to seal an assembly to prevent corrosion. Without a retaining adhesive, substrate selection for a reliable press or shrink fit may be limited because of the high levels of stress on the joined components. Only certain materials can withstand the stresses and forces required to merge the two parts. For example, powdered metal or aluminum may fail, whereas steel will easily achieve the required joint-strength requirements. A retaining adhesive strengthens the overall assembly, making substrate selection less critical to parts performance.

To determine the level of knowledge about and confidence in retaining compounds among engineers, Henkel recently worked together with Design Worldto conduct a survey of 400 design engineers. The study found that almost 42% of respondents use retaining compounds and select them based on their confidence in the materials resulting from previous experience. More than 20% of the responding engineers recognized that retaining adhesives can help lower overall assembly costs. Respondents agreed that retaining compounds increase the reliability of assemblies and that the combination of these adhesives and an interference or slip fit was very reliable, more so than with mechanical retaining methods alone. More than 60% of participants recognized that reducing the precision of dimensional tolerance also reduces the cost of manufacturing an assembly. The majority of survey participants experienced problems with fretting corrosion and stated that they could use retaining adhesives to solve this problem.

But that same survey also indicated that some 58% of engineers did not have specific retaining compounds in mind and may not yet be knowledgeable about the benefits of these adhesives. As a result, a brief tutorial on the technology seems in order.

Retaining Compounds

Retaining compounds are liquid anaerobic structural adhesives that cure or polymerize when confined without air between close-fitting metal surfaces. These adhesives are made from engineered plastics, materials used every day in designs to make products lighter and stronger. In terms of interference and slip fits, these engineered plastic adhesives allow designers to create joints that are high in strength, lower in weight and lower in cost than traditional interference fits.

Retaining compounds are specifically formulated to join cylindrical, unthreaded metal parts. These adhesives fill the empty space between mating interference fitted parts and cure to chemically unitize the assembly. Since the combination of the interference fit and the retaining compound is much stronger than the interference fit alone, engineers need not go to extremes to calculate dimensional tolerances.

The cured retaining adhesive fills the inner space between components and provides a physical and chemical barrier that eliminates fretting, oxidation, and galvanic corrosion. The adhesive also seals the interference fit joint against leakage.

Retaining compounds are used in three distinct ways for interference fitted joints:

1. Added to existing interference fit designs to increase joint strength and reliability

2. Engineered into new interference fit designs to deliver smaller, lighter-weight assemblies that operate reliably with relaxed tolerances requiring less precise machining

3. Used to structurally bond a slip fit that completely eliminates the need for an interference fit. Bonded slip fits require no machining to tight tolerances and are as reliable and effective as interference fits

Traditional interference fits generate strength solely from the metal-to-metal contact of surface peaks, an area that represents only 15% of the joint surface. Liquid retaining compounds fill the surface irregularities and clearance gaps between metal parts. They then cure to create a very dense and high-strength adhesive bond that increases joint strength and achieves maximum load transmission. The cured resin increases the area of surface contact to 100%, improving the distribution of stress and joint reliability and increasing part life.

Components bonded with retaining compounds do not require a fine surface finish and allow relaxed tolerances ideal for joining dissimilar metals. Adhesive bonded assemblies experience less stress in the joint and are more robust under differential thermal expansion. This means that softer substrates such as aluminum will not be damaged by force or thermal expansion and lose their interference.

Retaining compounds prevent fretting corrosion in interference fits. Fretting corrosion results when micro-movement occurs between a bearing and a shaft or housing, causing small sections of the assembly to weld together. The next time the assembly moves, these small welded sections rip off and result in a cratered surface. By filling the inner space between interference fitted parts, retaining compounds prevent the micro-movement that is the root cause of fretting corrosion.

Retaining compounds can replace brazing and welding with a quick and simple process that does not require specialized equipment, skilled operators, consumable components, or equipment maintenance. Unlike brazing and welding, retaining adhesives will not create inherent burn and fume hazards and can be quickly applied and cured.

Application and Removal

In their liquid form, retaining compounds may be applied using precision manual, semi-automatic, and fully automatic dispensing equipment.

An example of a fully automated high-precision dispenser is the Rotospray applicator, a specially engineered device that applies a metered amount of adhesive in a 360° bead or band onto a pre-defined location in the bore of a part. Rotospray application is precise and repeatable, and the applicator can be positioned on any axis and operated in either semi- or fully automated mode.

Hand pumps are precision applicators for manual dispense that control the volume and location of adhesive. The heart of the hand pump is an adjustable-stroke peristaltic pump that dispenses a metered amount of adhesive each time it is manually actuated.

Parts assembled with retaining compounds come apart with the standard disassembly methods for press and shrink fit components. These methods range from gear pullers to hydraulic oil injection and hydraulic presses. No special processing steps are required to break the adhesive bond. Engineers can select from either medium- or high-disassembly-strength formulations. Medium-strength retaining compounds may be preferred for joints designed for routine disassembly or service.

Advancements in Chemical Retaining

Recent advancements in chemical retaining have made these materials more robust. Formulated for simplified processing, the latest retaining compounds do not require cleaners, primers, or activators to enhance cure speed or strengthen bonds. Once assembled, they resist higher temperatures than earlier formulations.

While clean bonding surfaces deliver the best results for any assembly, the latest oil-tolerant retaining compounds are formulated to cut through oils and surface contaminants. The result is consistent bond strength despite variations in the cleaning process.

Figure 1 shows that, while clean surfaces deliver the best results for any assembly, the latest oil-tolerant retaining compounds cut through oils and contaminants. The graph illustrates the difference in bond strength between old retaining products and new formations when bonding contaminated surfaces.

In the past, a chemical activator or primer had to be applied to non-ferrous parts to cure anaerobic retaining compounds. The latest primerless retaining compounds cure on these surfaces as well as they cure on steel. The primer is no longer required to achieve polymerization, making the process more robust and eliminating an assembly step.

Size, weight, and efficiency are key parameters for most new interference or slip fit designs, targets that drive assemblies to higher operating temperatures. The latest temperature-resistant retaining compounds extend the continuous operating temperature ranges from -54°C to 230°C. Even when high temperature capability is not required, these formulations increase the safety and robustness of the assembly’s design.

Gold Medal Retaining

Pro snocross racer and freestyle rider Levi LaVallee, along with his gold-medal-winning snocross race team, relies exclusively on Polaris as his racing machine of choice. LaVallee holds nine Winter XGames medals, including six golds, and holds the world record for the 412.5-ft jump achieved on his snowmobile in 2010. Levi attributes much of his success to the reliability and performance of his Polaris sleds.

“The one thing that makes you feel good about doing crazy things like distance jumps and double back flips is knowing that, when Polaris is putting their sleds together, they’re using Loctite,” LaVallee says. “The racers that we’re running now are the Polaris IQR600. We’ve had that chassis for the last few years, and we’ve absolutely had phenomenal results with it, from XGames gold medals to the world distance jump to winning snocross championships. It’s just a great machine, and it says a lot about Polaris and how strong their equipment is, how well they build their machines.”

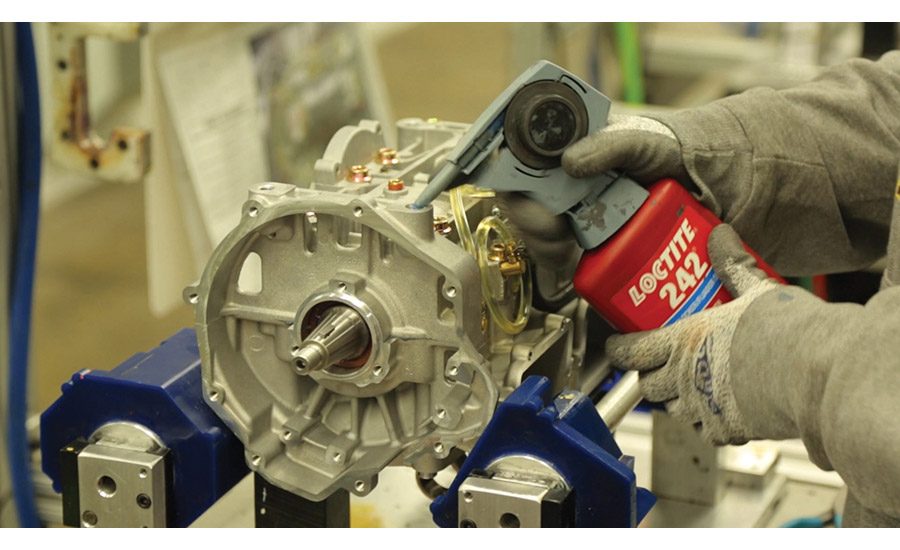

Polaris engineering specifies Loctite products throughout the manufacturing process. In addition to the threadlocking adhesives found on every threaded fastener assembly on the machine, Polaris has a number of retaining applications on its sleds.

These adhesives are critical on the main bearing interfaces. For bonding the snow drive clutch cover bearings and the moveable sheave bearings, the clutch has to operate reliably in an environment with temperatures ranging from -40°C to +90°C. In this case, Polaris engineers specify Loctite 648 to ensure that the bearings are fully seated and that they retain their position throughout the life of the machine. Loctite 648 high-strength bearing retainer provides excellent performance for dynamic, axial, and radial loads. The adhesive cures on metals without an activator and cures through contaminants including oils and cutting and corrosion-protection fluids, minimizing the amount of time spent cleaning parts.

On the snow clutch drive, Loctite 648 is hand-applied to the inner diameter of the moveable sheave, and the bearing is pressed into place. The retaining adhesive increases the component’s reliability and ensures that the bearing will not fail prematurely. In a second clutch application, Loctite 620 secures the spider assembly to the stationary shaft—possibly the most important part of the clutch assembly, since the weights react off the spider assembly and allow the clutch to function as expected.

For applications in the engine that reach operating temperatures of up to 230°C, Loctite 620 high-temperature, high-strength retaining compound endures temperature extremes. Designed specifically for engine applications such as retaining the crown shaft bearings, Loctite 620 is formulated to survive higher temperatures than the engine is likely to achieve at its hottest. To accelerate cure time during assembly, Loctite 7088, a non-aerosol primer stick, is applied to the fitting before adhesive is applied.

When LaVallee attempted his world-record distance jump on New Year’s Eve 2012, he blasted off the take-off ramp at 100 mph, launched through the air across part of San Diego Bay, and touched down forcefully more than 400 ft later. The sled was fine, despite having come down hard at 111 mph from a maximum altitude of approximately 70 ft onto a landing platform made of metal and wood. After some celebration, Levi jumped back onto the sled, which started right up and ran in top form. LaVallee credits Loctite threadlockers and retaining compounds for the health of his sled.

LaVallee also shared a very personal application for Loctite retaining compounds that he considers critical to his safety during freestyle competition. He defies gravity, flipping his 500-lb snowmobile high in the air while performing unbelievable jump flips. In 2013’s gold-medal-winning performance, LaVallee completed nine jumps in 75 sec and nailed huge extensions and perfect landings on a no-hands backflip, a no-feet backflip, and a backflip with his hands on the handlebars, but his feet off and fully extended to his back bumper. To control his sled and launch solid extensions during flips, LaVallee maintains a death grip on the handlebars.

“If your handlebars rotate forward or back, even just a little after you’ve clamped them as tight as you can, you can be in major trouble,” said LaVallee. “Before the competition, I asked Henkel if they could help me stop my handlebars from moving. They suggested using a retaining compound to lock the bars in place. I haven’t had an issue with movement since. Loctite is as good as gold.”

For more information, visit www.henkel-adhesives.com/automotive.