Adhesives and sealants manufacturers face unique challenges compared to other industries when undergoing lean or continuous improvement initiatives, including chemical reactions, vessels, batch sizes, curing times, long setups and required cleaning, regulatory mandates, and very technical processes that must be tightly controlled. None of these issues are addressed by the lean techniques that grew from the automotive industry in order to flow cars down a production line. So how can this industry create flow in its high-variety, complex environments? To start, operations must take a different approach to continuous improvement itself.

Continuous Improvement vs. Operational Excellence

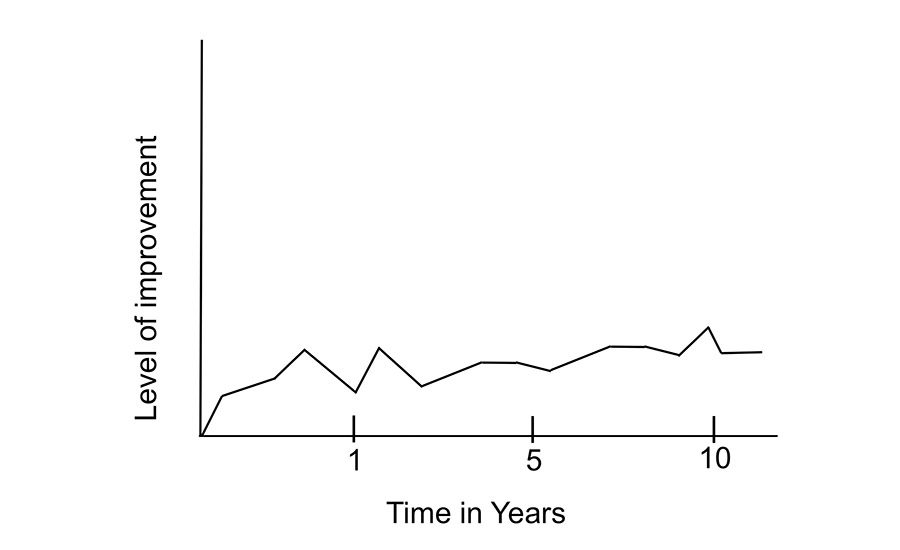

Traditionally, improvement activities consist of finding waste in the organization and eliminating it. Operations target areas for improvement, run improvement events or use lean tools to improve them, and then strive to sustain those improvements by implementing standard work, documenting, and measuring. While this seems like the right approach, a high-level look reveals it to be akin to the game Whac-a-Mole, where a company reacts to a problem area then reacts to a different area as problems arise. Over the long term, this process will, at best, result in only incremental improvements over time, which can be described as a staircase of continuous improvement. And at some point, organizations hit the lean plateau, which occurs when progress slows to a halt.

Instead of applying lean tools with the goal of waste elimination, operations can design how flow should work through their complex processes in order to deliver a product to the customer. Designing flow means designing the operation with a capability to cycle through different product mixes. That means connecting processes with FIFO (first in, first out) lanes, having stock raw materials that are pulled to point of use when needed, and other techniques that boil down to a new philosophy that high-performance companies are using in every industry: designing operations to achieve operational excellence. In operational excellence, companies do not try to look for problems and improve the operation each day. Instead, they design the operation in order to move its performance from point A to point B. To do this, it is imperative to know what Point B is.

Designing for Operational Excellence

Operational excellence can be practically defined as: “When each and every employee can see the flow of value to the customer, and fix that flow before it breaks down.” When companies reach operational excellence, each employee should not only know how to perform their work tasks, but also if the flow of the product to the customer is on time. Moreover, the value stream flow will be autonomous and self-healing; that is, managers will not have to oversee the operation and intervene on a daily basis because the employees working in the flow will be able to see if flow is normal and, if it is not, fix it before it becomes abnormal.

To achieve operational excellence, operations follow eight steps, in order:

1. Design lean value streams.

2. Make lean value streams flow.

3. Make flow visual.

4. Create standard work for flow.

5. Make abnormal flow visual.

6. Create standard work for abnormal flow.

7. Have employees in the flow improve the flow.

8. Perform offense activities.

The Importance of the Interval

The first step is particularly critical for processing adhesives and sealants. The key design guideline that applies to this industry is establishing an interval, which is the game-changer for designing flow in batch processing. The interval is defined as how long it will take an operation to cycle through the part numbers within a product family. A product family is a group of products that flow through the same equipment and have similar work content. (A value stream is the flow of a single product family.)

When product families are determined, there is usually a high variety of products that are made on the same equipment and have similar work content, especially in batch processing. That is because equipment is expensive and it can be difficult to dedicate to one or two products, so it is often shared among products. This means products are always competing for equipment time, but instead of searching for improved scheduling solutions like new software or simulations packages, there is a better approach. Rather than try to schedule equipment to match orders, an operation should define a length of time in which it can run all active products across the equipment. For example, a design parameter could be set up that states: We will build every product that goes through this mixer every two weeks. In that case, the interval is two weeks. If the criterion is that the operation will build every product every week, then the interval is one week.

When orders come in, the operation breaks them up by part number mix, not volume. Hence, it would look at the number of part numbers that need to be produced, and compare it to the designed interval. If it is equal to or less than the interval, then the operation determines how much volume it can run for each part needed. This means an order may be broken into two to three lot sizes if there is a need to produce something else that is sold to another customer. However, it is important to note that an operation would not break up a batch if there is not a demand to; the existing order would simply get “two slots” in the interval.

Capability, not Capacity

In addition to establishing the interval, it is also important to change an operation’s vocabulary a bit. In traditional terms, “capacity” equals “volume.” But in high-mix environments, a better term is “capability,” which means how much volume and mix an operation can handle. For example, for a given product line, a good way to describe the line’s capability is to say that the company can produce X amount of pounds each week comprised of 20 different part numbers.

The impact of capability goes far beyond the shop floor. It is a direct link to how well a company can satisfy customer demand as well, and even changing customer demand. Establishing a capability for each product family allows sales to know if the operation is within capability and sell to that capability since it knows it can take both the small and large orders. In addition, the interval will establish a guaranteed delivery time for the customer, which provides reliable delivery every time. Sales staff will know whether, when the customer asks for something, it is within the capability of the operation to deliver within the required timeframe. Sales will know this instantly, allowing them to tell the customer what they can deliver and when, with certainty.

Even with the industry’s specific challenges, adhesive and sealant manufacturers can achieve flow in their high-variety environments. The first step is to set a destination, and design flow to achieve that destination. Next, companies apply guidelines to design the flow rather than brainstorming, running Kaizen events, or employing rapid improvement techniques. Finally, establishing the interval is key to batch processing and linking the capability of the operation directly to sales and the customer. And when customers are happy, businesses grow. ASI

For more information, phone (401) 667-0117, fax (401) 667-7298 or visit http://instituteopex.org.