A caulking sealant has three basic functions: filling a gap between two or more substrates; forming a barrier through the physical properties of the sealant itself and by adhesion to the substrate; and maintaining sealing properties for the expected lifetime, service conditions, and environments. To help maintain flexibility at low temperatures and to retain performance, most pigmented acrylic latex sealants on the market today are formulated with a supplementary external plasticizer. When properly chosen and formulated, plasticizers such as benzylbutyl phthalate, dipropylene glycol dibenzoate or others effectively lower the glass-transition temperature (Tg) of acrylic polymers and thus “soften” the composition.

At the same time, heavy reliance on plasticizers in a sealant formulation can result in negative side effects, such as mildew growth or glossing. In addition, the use of phthalate plasticizers has recently come under scrutiny due their poor toxicological profile. For these reasons, product developers are beginning to look at new latex binders that allow for the elimination or significant reduction of plasticizers from the formulation. New technologies in this area offer many benefits and may help formulators improve product performance while still achieving the flexibility of high-plasticizer products.

It is first important to understand the historical importance of plasticizers and how they are used today. Waterborne acrylic latex sealants generally offer excellent durability in terms of ultraviolet light resistance and chemical resistance. Further, they offer desirable application properties such as ease of gunning, tooling and cleanup; the elimination of solvent odors and flammability; and the ability to be painted shortly after joint placement. Highly plasticized systems yield flexible sealants with movement capability of ± 35% and the ability to meet the performance requirements of high-performance sealants such as ASTM C 920.

Plasticizer Migration

It is not uncommon for acrylic-based sealant formulations to contain as much as 40 wt% plasticizer. However, the reliance on high levels of external plasticizer to achieve acceptable low-temperature flexibility may create a host of problems, including:

- Dirt pickup and mildew growth

- Hardening on aging

- Paint discoloration

- Glossing

Plasticizer migration is key to all of these problems. Plasticizer migration to the sealant’s surface can promote microbial growth by acting as a nutrient or merely by increasing surface tack such that airborne nutrients adhere to the sealant. Thus, they can impart their own biological properties to an otherwise inert polymer system. Factors that can influence the rate of microbiological growth include: moisture, temperature, nutrients and the presence of anti-microbial additives.

Plasticizer exudation also results in hardening of the sealant with age, which risks cohesive or interfacial joint failure. This aging can be dramatic and can occur in as little as a few years. It is possible for externally plasticized acrylic sealants to lose as much as 25% of their flexibility due to plasticizer migration.

Finally, exudation and migration of plasticizer from the sealant can impact the appearance of paints applied over the sealant. The plasticizer can soften the paint film, increasing its tendency to pick up dirt and support mildew growth. Plasticizer can also discolor or increase the gloss level of the paint film.

Reducing or Eliminating External Plasticizers

Due to the many detrimental effects experienced through the use of external plasticizers, their elimination would be expected to improve the performance characteristics of a sealant, provided the polymer is sufficiently soft to ensure adequate flexibility. As a result, product developers in the industry have developed binder solutions that do not require the use of external plasticizers. For example, a recently introduced latex* for high-performance caulks and sealants offers excellent exterior durability and adhesion while enabling formulators to prepare a range of ASTM C834- and C920-compliant sealants. Its low Tg temperature allows for the formulation of sealants with outstanding low-temperature flexibility without the need for external plasticizers.

The toughness of sealants formulated with external plasticizers is generally much poorer than those without them. As a result, sealants free of external plasticizer can exhibit much higher elongation without compromising their tensile strength (see Figure 1, p. 19).

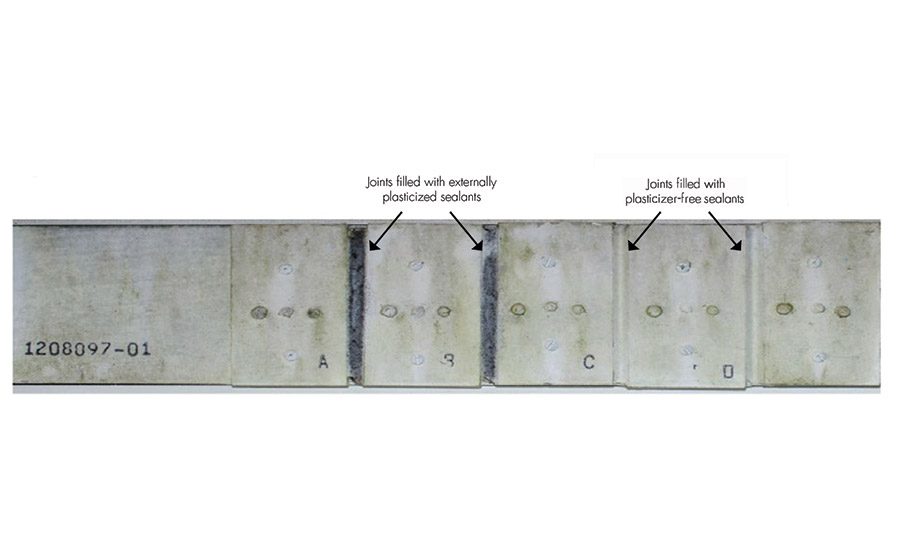

The elimination of external plasticizer has the added benefit of improved dirt pickup and mildew resistance. This is illustrated by comparing the dirt pickup and mildew resistance of a conventional, externally plasticized sealant to one formulated with this latex and no external plasticizer (see Figure 2).

This improvement in dirt pickup and mildew resistance is irrelevant if the sealant does not demonstrate acceptable flexibility. Figure 3 shows four years of exterior durability testing that demonstrate the sealant formulations based on the latex not only yield excellent dirt pickup and mildew resistance, but also excellent crack resistance.

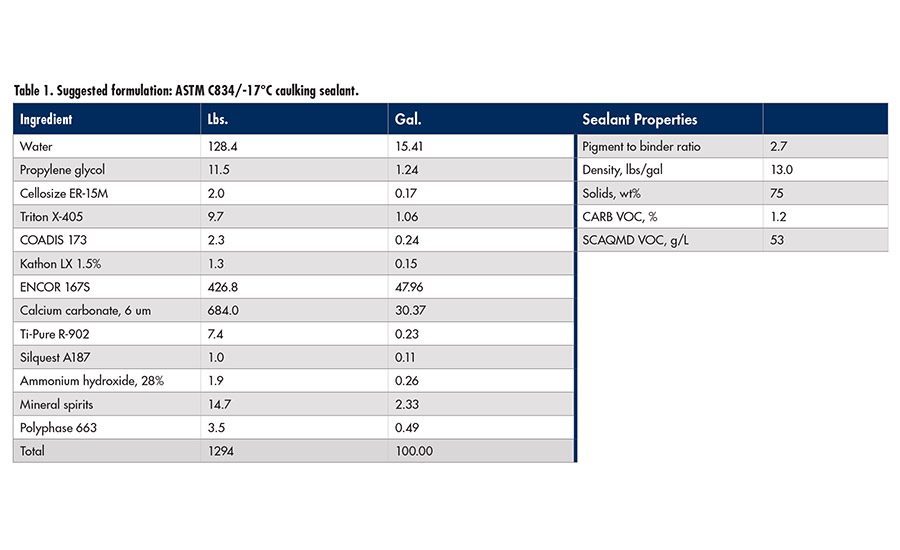

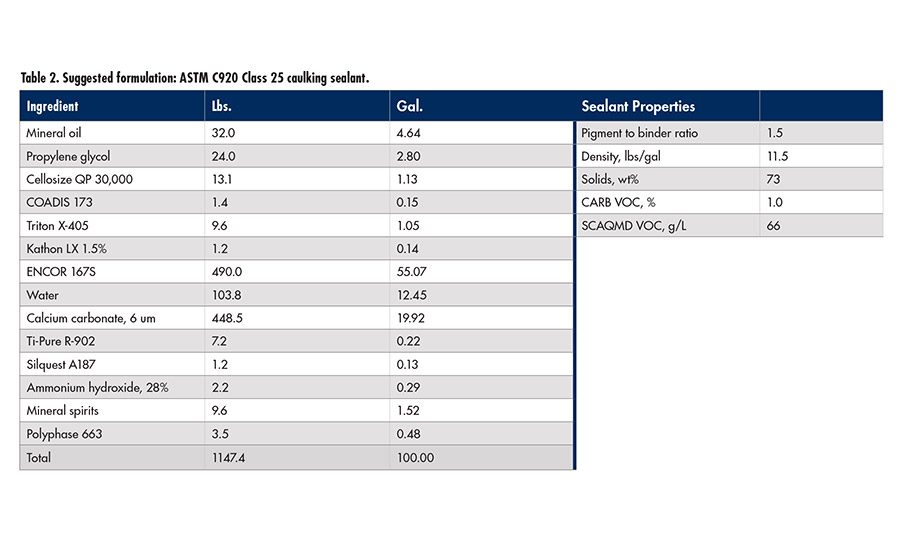

As illustrated in Tables 1-2, sealant formulations that meet the performance requirements of ASTM C 834 and C 920 are readily prepared with the latex without the need for external plasticizer. The addition of inert fillers can significantly lower the cost of a sealant formulation, but this comes at the expense of low-temperature flexibility. Formulators may choose to use external plasticizer with the latex to achieve acceptable performance at higher pigment to binder ratios. The latex is compatible with many of the newer non-phthalate plasticizers. Due to its inherent flexibility and toughness, the latex has been found to require lower levels of external plasticizer to achieve good low-temperature flexibility at any given P/B ratio. ASI

For more information, visit www.arkema.com.