The two-part formulation is used to protect circuit boards and components from harsh conditions, such as moisture, high/low temperatures, and physical or electrical stress. Once potted in an enclosure, the unit is typically mounted on the chassis or drive train of heavy machinery such as a tractor or steer loader, where operating temperatures generally range from -40ºC to 85ºC (-40ºF to 185ºF). The potting operation is one example of a manufacturing process that has earned Phoenix products a reputation for exceptional reliability.

A Flexible System

The dispensing system is provided by Fluid Research Corp., Costa Mesa, Calif. According to Phoenix Lead Manufacturing Engineer Mark Nyland, “For us, the key features of the FRC Advantage Work Station® are its shot-size accuracy and range. With the machine’s adjustable flow rate and predictable, consistent ratios, we have a very repeatable process.“Every time we set up a program, a ratio test is performed to check for variation,” he explained. “With this material, we could handle up to 5% deviation in the mix ratio, but during the nine months since we’ve acquired the FRC machine, the maximum fluctuation has never been anywhere near that,” Nyland added.

When initially qualifying the dispensing system, Phoenix did a matrix comparison with other equipment in the industry. “We found other systems that could deliver a range of 2 to 30 grams of material, but larger-volume requirements would have meant purchasing another machine or extensively revising an existing design,” he observed. Current production at Phoenix includes shot sizes ranging from 9 to 400 grams, but future designs are expected to require accurate delivery of just 2 grams of material.

“The flexibility of this dispensing system is a major benefit,” Nyland continued. “The ability to provide a wide range of shot sizes is important to our type of operation, especially in the lower-volume applications,” he said. “We also like the quick setup and changeover time.”

Manufacturing Process

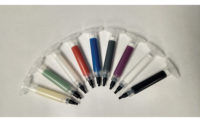

Phoenix technicians program the ratio, flow rate and quantity of the potting compound to be dispensed via the system’s LCD touch panel. The circuit board is then placed under the dispensing machine’s static-mixing nozzle, and the technician simply depresses a foot switch to release the programmed amount.“The computer-based system allows fast setup, and operators can adjust and store multiple flow rates, mix ratios and even entire dispensing cycles,” commented Fluid Research President Mike Engle. The optically encoded servo drives and microprocessor-controlled hardware are driven by FRC programming technology that delivers extremely accurate and repeatable shot sizes anywhere from 1 cc to many gallons.

“With the components mixed in a static mixer after flowing from the Stat-A-Seal™ Dispense Head, the positive-shutoff valves prevent cured material from clogging the lines,” Engle explained. “And because it requires no dynamic shaft seals, the progressive-cavity design eliminates the valve wear, leakage and potential phasing errors common to piston-pump systems,” he added.

The new equipment replaces labor-intensive procedures that required manual mixing and dispensing of the potting compound. Before acquiring the new, automated system, the company was buying the potting material in kits where the resin and catalyst were separated by a piece of foil. Operators would manually mix the material in the kits and then dispense into the units to be potted.

“The cost of buying the material in kits, plus the labor involved, proved to be very high. According to our calculations, the justification for purchasing this new dispensing system was that it would pay for itself in roughly one year,” said Nyland. The company now purchases the material in 55-gallon kits, and allows the equipment to handle all mixing and metering chores.

For more information on liquid control systems, contact Fluid Research Corp., 3505 Cadillac Ave., Costa Mesa, CA 92626; phone 714-513-2350; fax 714-513-2351; or visit www.fluidresearch.com.

For more information on circuit board manufacturing, contact Phoenix International Corp., 1441 44th St., N.W., Fargo, ND 58102; phone 701-282-9364; fax 701-282-9365.