Figure 1. The PicoDotTM jet dispensing system is a non-contact dispensing system that uses piezoelectric technology to apply small, precise amounts of assembly fluids.

As today’s products continue to pack more features into smaller packages, tolerances keep getting tighter and tighter. This makes consistent size and placement of adhesives, lubricants, coatings and other assembly fluids more critical than ever.

To help manufacturers meet this challenge, EFD (East Providence, RI) has developed the PicoDotTMjet dispensing system - a non-contact dispensing system that uses piezoelectric technology to apply small, precise amounts of a variety of fluids.

With the ability to apply consistent shots as small as 2 nanoliters at speeds up to 150 dots per second, the PicoDot system is ideal for high-speed, high-volume applications that require many small, precise fluid deposits. The narrow design of the valves, with a width of approximately ½ inch, makes them particularly well suited for installations where space is tight or valves need to be mounted close to each other.

Because the valve nozzle does not contact the substrate, the Pico Dot system is also a good choice for applications where controlled amounts of fluid must be applied on surfaces that are not perfectly flat, such as printed circuit boards. Eliminating contact with the substrate also eliminates the need for vertical Z-axis movement and precise height positioning, which can significantly increase production speeds.

The PicoDot's range of possible applications is huge. Sample uses include electronics (bonding cell phone speakers with UV-cure adhesives), life sciences (attaching needles to medical syringes), and precision mechanical applications (jetting small amounts of grease on micro gears).

How Piezoelectric Valves Work

Piezois Greek for “pressure.” When pressure is applied to certain crystalline materials, such as quartz, it creates voltage. Conversely, when voltage is applied to a crystal, the crystal changes shape. This concept is the basis for the PicoDot system, which consists of three separate components: a jet valve, a valve driver and a valve controller.

Figure 2. PicoDot Valve in closed position.

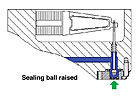

The PicoDot jet valve contains two piezoelectric actuators composed of stacked ceramic coins that expand and contract in response to changes in voltage supplied through the valve driver. Both actuators are connected to a vertical rod that has a ceramic sealing ball attached to its lower end. When the valve is in the closed position (see Figure 2), the ball is seated in the valve nozzle.

Figure 3. PicoDot Valve in open position.

The extremely fast action of the piezoelectric actuators makes it possible to dispense fluid continuously at speeds of up to 150 cycles per second. Depending on the fluid being dispensed, the system can produce consistent shot volumes as small as 2 nanoliters, and the high resolution of the PicoDot valve controller (0.01 milliseconds) makes it possible to adjust deposit size with exceptional precision.

PicoDot valves are available in several different configurations to handle fluids ranging from 50 to 500,000 cps. The LV configuration is designed for use with low-viscosity fluids from 50 to 1,000 cps; the MV configuration covers a range of viscosities from 50 to 200,000 cps; and the HV configuration is specifically designed for fluids with high viscosities of 1,000 to 500,000 cps. Nozzles are available with 150µm, 200µm, 300µm and 400µm orifice diameters to accommodate a range of dot sizes.

In order to determine the optimum valve/nozzle combination for specific applications, EFD has set up labs globally where customers can have their fluid tested according to their process requirements and receive a report with the initial valve driver and controller settings for use as a baseline in an actual production environment.

Most PicoDot valves, except those used exclusively for low-viscosity fluids, incorporate a heater near the fluid channel in order to thin the fluid to its optimum jetting viscosity. Depending on the rate of consumption, fluid can be supplied to PicoDot valves from syringe barrels, tanks or drum unloader systems.

While PicoDot valves will dispense a variety of fluids, including many particle-filled materials, they are not suitable for use with anaerobics or fluids with a pot life of less than four hours, due to the risk of these materials curing inside the valve.

Valve Driver

Each PicoDot valve is powered by a valve driver, which contains the amplifier used to generate the signal for the piezoelectric actuators.

Valve drivers, except those used for low-viscosity fluids, also contain a temperature controller for the heater in the valve. Temperature adjustment affects the temperature of the valve body, which, in turn, affects the temperature of the fluid being dispensed. The maximum temperature attainable is 100°C (212°F) or 180°C (356°F), depending on the driver model. Temperature can be adjusted with the potentiometer on the valve driver, with the PicoDot valve controller (described below), or with a programmable logic controller (PLC) connected to the interface in the valve driver.

Figure 4. A user-friendly menu system makes it easy to set fluid application parameters.

The PicoDot valve controller is available in 2- and 4-channel configurations. Both versions feature a graphical digital display and a user-friendly menu system (see Figure 4) that makes it easy to set the fluid application parameters for each valve. Complex jetting processes can easily be created on a PC and downloaded by way of the integrated SD card slot. A password protection feature ensures that standard procedures are not changed accidentally, helping to achieve repeatable results.

Figure 5. Sample PicoDot system settings for different fluids.

In general, longer open times, higher pulse counts and higher fluid pressures will produce larger dots, while shorter nozzle-to-substrate distances will produce more well-defined dots.

Long, Trouble-Free Operation

PicoDot jet valves are designed for long, trouble-free operation and require only minimal maintenance, due to the arrangement of the piezoelectric actuators and the wear-resistant ceramic valve seat.The piezoelectric actuators have a working life of 100,000,000 to 350,000,000 cycles, depending on the jetting frequency and the temperatures used. Preventive maintenance consists of checking the valve seat after every 10,000,000 cycles. Cleaning is easy to perform and involves flushing the fluid channel and cleaning the nozzle plate and sealing ball with a solvent recommended by the fluid manufacturer.

Summary

The PicoDot jet dispensing system is a reliable, innovative option for manufacturers seeking to improve process control and reduce costs through exceptional fluid deposit repeatability at high production speeds.For more information, contact Torsten Brieger, tbrieger@efd-inc.com.