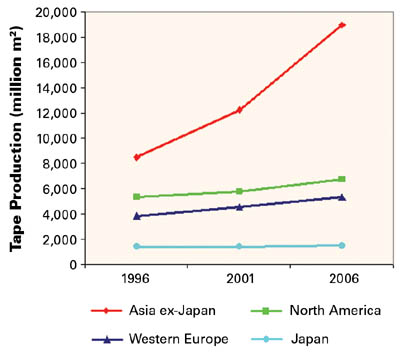

While production of pressure-sensitive adhesives (PSAs) continues to grow at a pace of 3-4% per year in Europe and the United States, the growth rate is much faster in Asia. As can be seen in the figure, Asian production of pressure-sensitive tapes grew 8-9% from 1996-2001, and is predicted to continue at this rate through 2006. By that time, production in Asia will be three times that of North America. As in many other industries, Asian manufacturers enjoy significant production cost advantages and have begun to exploit them in the adhesives market. A large portion of the Asian product is ultimately intended for export, either as a pressure-sensitive product or as a sub-assembly.

Increased Market Competition Requires Innovation

With price constraints intensifying in many of the traditional applications for pressure-sensitive adhesives, what must established producers do to remain profitable? The same thing they have always done - find new and innovative ways to create value. Silicone PSAs have many unique advantages that make them suitable for high-value applications. Some of these applications involve replacement of mechanical fasteners in the automotive, appliance and aerospace industries. Others include the use of silicone PSAs in the manufacture of windows, electronic signs, insulated pipes and other products exposed to outdoor environments.Many of these new high-value application opportunities exist within the labeling market. Long a mainstay of organic PSAs, silicones have not yet penetrated significantly into this market. Silicones, which perform well at temperatures from -100-500°F (-75-260°C), are an obvious fit for applications in which the product must perform at temperature extremes. Other potential applications include those requiring adhesion to low-energy surfaces, such as silicone-coated substrates like release liners and coated textiles, or areas with oil contamination, such as a mold release and certain low-surface-energy plastics. Environmental resistance - whether to UV, thermal or chemical attack - is another important driver for these new applications.

Moving Beyond High-Temperature Applications

Silicone PSAs are traditionally associated with high-temperature applications - more specifically, high-temperature tapes. Most silicones maintain adhesion at temperatures in excess of 500°F (260°C). While this is the most obvious advantage of using silicone adhesives, these products have many other valuable attributes, including the following.- Low-temperature performance

- Adhesion to low-energy surfaces

- Conformability and low residue

- Chemical, moisture and UV resistance

- Sound-dampening characteristics

- Electrical insulation properties

- Non-toxic and non-allergenic features

A variety of industrial applications, such as printed circuit masking, electrical insulation for high-temperature service and plasma spray applications, currently take advantage of silicone's performance attributes. It is also used in powder-coating operations, an application that capitalizes on silicone's chemical resistance. Finally, because of their adhesion to low-surface-energy substrates, silicone PSAs are used as splicing tapes for silicone-coated release liners.

One reason for silicone adhesive's lack of penetration into the labeling market is its delivery system. All silicone PSAs are currently supplied as 55-60% solids solutions in either toluene or xylene. According to a 2003 survey conducted by SpecialChem (http://www.specialchem.com ), the primary concern of most adhesives formulators (37% of all respondents) is the replacement of solventborne adhesives with more environmentally friendly alternatives. Unfortunately, only adhesive users who are willing to handle solvent have been able to use silicone PSAs. This has severely limited the use of silicone PSAs to manufacturers who have existing solvent removal equipment. Most of these companies produce tape constructions - not labels.

New Products Offer Solutions

Recently, Dow Corning has worked to develop products that will help to overcome the traditional limitations of silicone PSAs. Late last year, the company introduced Dow Corning" 7500 Adhesive, the first screen-printable silicone adhesive available. This adhesive can be used in a variety of applications such as electronics assembly, semiconductor processing and general industry assembly - anywhere flexible assembly is needed.Dow Corning® 2013 Adhesive has similar properties to typical solventborne silicone PSAs, but without the solvent. It cures by way of a thermal cure cycle, produces no byproducts and is available in a viscosity range comparable to most similar adhesives (20,000 cSt).

In a market where growth is difficult, innovation is imperative. Dow Corning is meeting that challenge by removing the traditional limitations of silicone PSAs and creating growth opportunities with high-value applications that take advantage of the unique properties of silicone.

For more information, visit http://www.dowcorning.com/psi .