The growing demand for ultra-clear tapes and labels, as well as the increased use of plastic parts in automobile design and manufacture, has made formulating adhesives more difficult. Many of these substrates present unique adhesion challenges. In addition, adhesives for these higher-end uses require excellent clarity and long-term color stability. These demanding criteria necessitate using well-designed tackifiers to meet these stringent requirements.

Formulating adhesives with hydrogenated rosin resins can help enhance adhesion to difficult substrates while maintaining the color, clarity, heat and age stability of the adhesives. These resins also help to achieve strong long-term adhesion with the right balance of cohesion, creating superior properties. This article offers a brief look at the characteristics of hydrogenated rosin resins, and discusses the core benefits of formulating these resins into high-performance adhesives.

A Stable, Compatible Resin

Rosin and rosin derivatives have long been produced and remain excellent tackifiers for adhesives. They offer three important formulation benefits: compatibility with a variety of polymers, which provides formulation flexibility and reliability; the ability to be chemically tailored to provide unique adhesive performance; and they are derived from a renewable, natural source.

Although rosin resins are highly susceptible to oxidation, they can be stabilized through hydrogenation. Hydrogenation reduces oxygen uptake in the resin and produces a tackifier with significantly lighter color. These more thermal and oxidatively stable rosin-derived resins extend the life of hot-melt adhesives (HMA). Eastman's Foralyn and Foral E rosin resins are hydrogenated to provide these important properties. In addition, Foralyn rosin resins are further processed to reduce their odor. This can be important during both adhesive production and use.

Why Use Hydrogenated Rosin Resins?

In formulating adhesives for difficult substrates, formulators need a tackifier that achieves the optimum combination of adhesion and initial clarity, oxidation, and thermal- and long-term aging stability, as well as the right resin/polymer compatibility. Resin/polymer compatibility determines the strength of the adhesive bond to the substrate, and initial clarity, color, and aging stability are key indicators of adhesive quality.Simple rosin esters offer excellent adhesion to many surfaces but do not have the stability and clarity that end users require. Conversely, hydrogenated hydrocarbon resins provide good clarity and stability, but do not adhere well to low-energy surfaces. Hydrogenated rosin resins provide an optimum combination of adhesion, clarity and stability. These benefits translate into important production and performance attributes for formulating higher-end adhesives for plastic assembly and other uses.

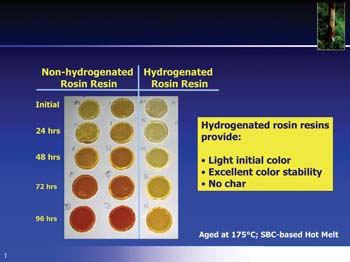

Thermal stability enables resins to sustain high temperatures for longer periods of time, increasing the processing window of an HMA from 24 hours to as much as 96 hours, thus reducing adhesive waste. Heat stability also prevents gel formation during processing and on production gluing equipment, thus eliminating an expensive and time-consuming process that can slow worker productivity and increase equipment downtime.

The degree of hydrogenation for a resin used in a hot-melt pressure-sensitive adhesive (HMPSA) determines thermal and color stability. Figure 1 shows that, at processing temperatures of 175°C, highly hydrogenated rosin resins exhibit no char or gel formation, and less color degradation over time, than non-hydrogenated resins.

Managing Compatibility with Hydrogenation

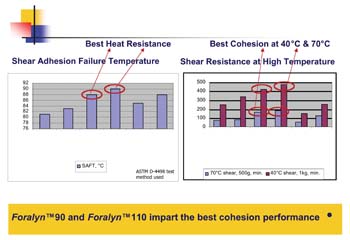

The degree of hydrogenation of a rosin resin also determines the compatibility of resins with various polymers, and therefore the resulting strength of their adhesive and cohesive bonds. The high polarity and low molecular weight of these resins, as compared to other tackifiers, give strong grip with good cohesive performance, particularly on low-surface-energy substrates such as PP and PE. Due to their aliphatic character, hydrogenated rosin resins are compatible in all ethylene-vinyl-acetate (EVA) types and amorphous poly-alpha olefins (APAOs), styrene-isoprene-styrene- (SIS), styrene-butadiene-styrene- (SBS), and polyisobutylene- (PIB) based adhesives, as well as in popular acrylic adhesives.Tables 1-2 show the overall impact of hydrogenation on adhesion and cohesion. These tables highlight Foralyn and Foral E hydrogenated rosin resins, formulated into an HMPSA formulation used for specialty tape applications. The figures show equal or better adhesion than non-hydrogenated resins, and excellent cohesive performance at higher temperatures.

Formulating for block copolymers is a particular challenge because they exhibit two glass-transition temperatures - one for the mid-block and one for the end-block. Again, hydrogenated rosin resins are an excellent formulating choice because their range of compatibility helps balance adhesive and cohesive properties in block copolymers.

As shown in Table 3, in styrene block copolymer- (SBC) based adhesives, the high mid-block compatibility of the hydrogenated resin results in excellent adhesion, initial tack and optimum wetting out. The low end-block compatibility results in excellent cohesion with better shear resistance and a slightly higher viscosity at higher processing temperatures. An SBC-based PSA formulated this way, such as a repositionable adhesive for automobile carpets (known as a "peel and stick" application), would produce a clear adhesive with strong grip and enough cohesive strength to allow the repositioning of a poorly positioned carpet with no detrimental effects.

Formulating adhesives for difficult substrates, such as polyethylene or foams, can be tricky. Formulators should consider a tackifier resin that exhibits good wetting out, good thermal stability and the right polymer/resin compatibility to ensure strong adhesive and cohesive perfor-mance, as well as manufacturing ease. Hydrogenated rosin resins are an excellent choice for such formulations because they offer a reliably strong bond.

Conclusion

Hydrogenated rosin resins, such as Foral E and Foralyn, provide adhesive formulators with a powerful combination of stability in processing and end-use application. Their compatibility and adhesion characteristics prove useful in formulating a variety of high-performance adhesives for difficult substrates.

About the Author

Derek Bamborough is technical marketing manager, adhesives and polymers, Eastman Chemical Middleburg BV, The Netherlands. He holds a bachelor's degree with honors from Exeter University in organic chemistry and geology.

For more information, contact Derek Bamborough at (800) EASTMAN or visit http://www.Eastman.com.