The world has a major counterfeiting problem. Counterfeiting is an issue not only with currency, but in luxury and everyday goods markets, as well as dangerous realms such as pharmaceuticals and chemicals. The value of counterfeit goods worldwide is currently calculated at $653.77 billion, according to Havocscope, meaning there is a lot more that could be done to fight back against this crime that affects brand reputations, company revenues and consumer safety.

While not necessarily an outright solution to the problem by themselves, security labels are a compelling means of cost-effectively deterring and detecting counterfeiting across industries.

What is a security label?

Security labels describe labeling solutions designed to create an often-multilayered defense against counterfeiting, tampering or other criminal activity. Security labels can vary greatly in construction, from the very simple to the extremely advanced, and may be either intentionally obvious to consumers (allowing them to detect a broken seal or other tampering) or covert in nature (allowing informed parties to detect differences between real and counterfeit goods).

Security measures can be integrated into every part of a label to provide a multilayered defense against counterfeiting. Examples include:

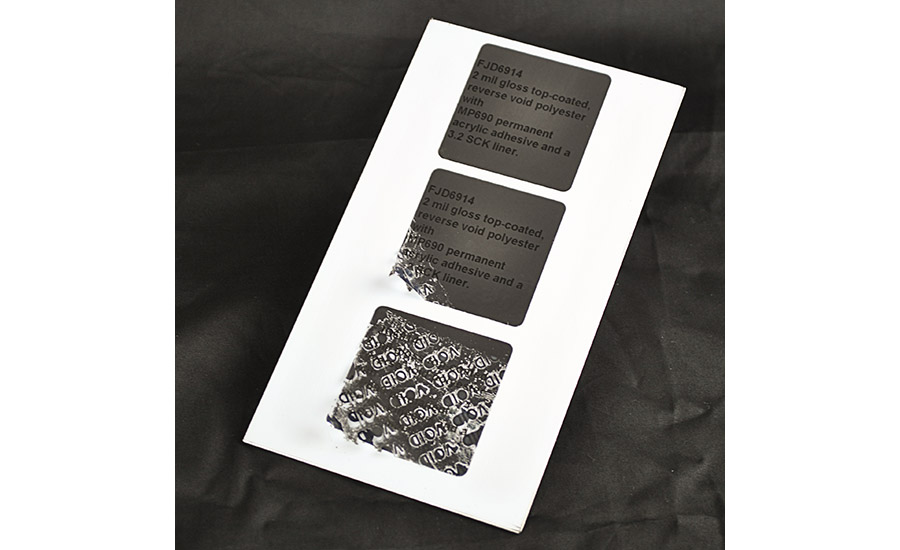

- Tamper-evident security measures – One of the most cost-effective and basic means of improving product security, tamper-evident measures are intended to let you know if an enclosure or product has been accessed when it should not have been. Examples of these measures include destructible facestocks that irreparably break upon removal attempts and clear permanent adhesives that leave behind residue to indicate removal.

- Printed security measures – Very small or hidden codes are sometimes printed onto labels, but require significant magnification or other methods to detect. Some organizations even use decodable hidden graphics generated by closely protected software, the absence of which would indicate counterfeiting.

- Taggant security measures – Some companies mark products by inserting difficult-to-obtain materials into adhesives or topcoats, later detecting their presence (or lack thereof) using forensic methods. Even if detected, the limited nature of taggant materials makes them tough to duplicate.

- Ink-based security measures – Sometimes adhesives and facestocks may contain no security measures, with specialized inks used instead. Iridescent inks that change color based on viewing angle or thermochromatic inks that change color based on temperature are two examples. Inks can sometimes be tested easily (using a finger or ice cube) or only via a specially equipped laboratory.

Where do we see security labels used?

You have probably seen many security labels over time; you just may not have realized it. Consider the last time you filled up your car at the gas station, for instance—there may have been “void labels” adhered to the payment system enclosure on the pump so that any attempt to open the door would result in obvious evidence of tampering, such as the word “VOID” permanently adhered to the surface. Void labels are also used on durable goods, to seal off restricted areas such as airplane cabins, and in simpler applications like food, health and beauty, pharmaceutical and other packaging types. We also see some of the more advanced anti-counterfeiting measures being deployed to protect brand image and consumer safety in spirits, luxury goods and pharmaceutical markets.

How do you choose security measures?

If you are considering adding security measures into a permanent labeling application, talk with your printer or labeling product manufacturers, as they may offer training on use and recognition of security labels. At the very least, they may be able to offer insights into what sort of measures make sense for your application. Just be sure you ultimately work with suppliers that possess the expertise, security and secrecy necessary to make your security labeling application a success.

This post is part of a series on permanent labeling called The Permanent Record. You can find the previous post here. Check back soon to learn about how durable labels can be used to provide important instructions and ratings information on durable goods.

Recent Comments

I recommend you to try https://edureviewer.com/services/quizplus-review/ ....

I think that you are right, now there...

You are right, now people have begun to...

Good experience after reading. In fact, now many...

Good idea, although I'm now increasingly shopping online,...