Across industries and across the world there exist applications that require deployment of durable labels to maintain compliance with regulations and specifications. These labels typically convey pertinent information about the products to which they adhere, offering warnings of danger, instructions for safe handling or usage, and other crucial messaging. As a result, it is crucial that these labels go on and stay on a substrate, while also standing up to whatever conditions an environment may throw at them.

Compliance labeling may sound complex, and to be honest, it can be. There is good reason for this, however, as demanding applications and hazardous situations require specialized attention. Keep the following three tips in mind, and you should be positioned for success.

1. Know Your Application Requirements

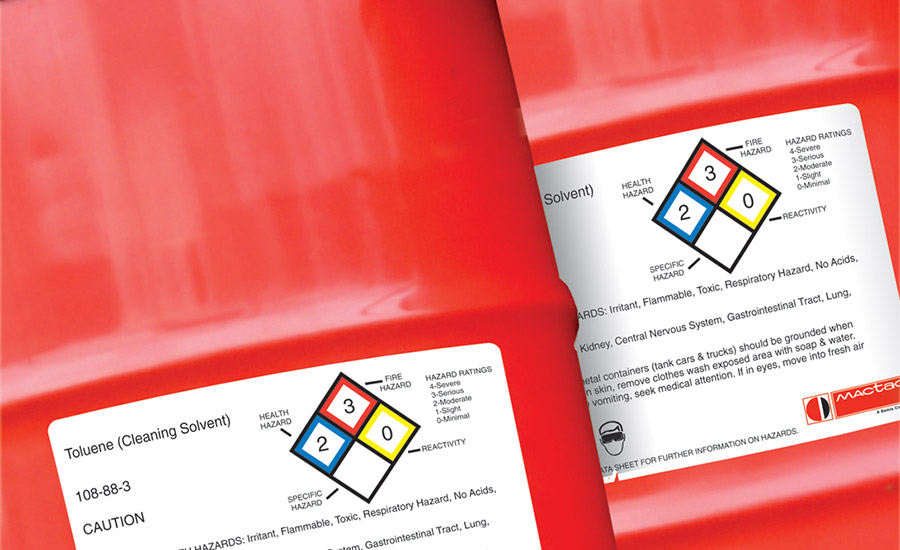

The more you know about an application, the better informed your durable label choices will be. Take drum container labeling, for instance. A huge number of drums travel by sea annually carrying chemicals, petroleum, coatings, food, additives and other materials. Durable labels are applied for identification and warning purposes, and they must stand up to harsh conditions during shipping related to weather (rain, snow, sunlight), extreme temperatures, abrasion, chemicals/solvents, and sea water. Knowing the application means you can make informed choices when selecting label materials that will withstand the environment and meet all applicable standards.

Beyond marine-based drum applications, compliance labeling plays a prominent role in the pharmaceutical, medical device, electronics and power tool markets, among others. In each instance, durable labels are ensuring critical warnings and usage information remains adhered and legible to prevent costly mistakes. OSHA predicts, for example, that Globally Harmonized System of Classification and Labeling (GHS) standards for chemical drum labeling prevent 43 fatalities, 585 injuries and $500 million in costs per year.

2. Know What Labeling Materials Suit Your Needs

Given that durable labels must remain adhered to a designated substrate for extended periods of time, long-lasting permanent adhesives are needed. In our drum labeling example, we would likely want an acrylic adhesive, as acrylics exhibit strong chemical/environmental resistance and tend to stick well on coated metal surfaces. We would also want to choose a durable facestock that will last, but exhibits proper conformability to curved surfaces—vinyl would likely work well, or perhaps polypropylene with UV inhibitors. The right material choices all depend on the specific application, but if you need help, reach out to your labeling materials providers—we can steer you in the right direction.

3. Know What Guidelines Govern Your Labels

Regulators will ultimately check your labels for conditions like flagging or tunneling, as well as any damage that might jeopardize legibility. You may have several different sorts of regulatory bodies laying out guidelines for your application—marine drum shipments are governed by everything from the U.N.’s GHS standards to the International Maritime Organization’s International Maritime Dangerous Goods (IMDG) Code to other merchant shipping regulations, for instance.

It is worth noting that regulatory enforcement is being stepped up in many instances, too. GHS compliance is mandated by OSHA as of mid-2015, for example, and UL is getting involved in BS 5609 British Standard drum label testing now. We are also seeing more unique device identification (UDI) requirements in the medical device field of late, as well as increased scrutiny of durable labels in other fields.

As a general rule, make sure you are staying on top of changing regulations that could affect you and ensure any durable labeling applications with which you are involved meet applicable compliance standards. If you need assistance, label material providers or regulatory organizations are often great resources.

This post is part of a series on permanent labeling called The Permanent Record. You can find the previous post here. Check back soon to learn about durable labels used to fight counterfeiting and unauthorized tampering.

Recent Comments

I recommend you to try https://edureviewer.com/services/quizplus-review/ ....

I think that you are right, now there...

You are right, now people have begun to...

Good experience after reading. In fact, now many...

Good idea, although I'm now increasingly shopping online,...