Throughout this article we will refer to the process of creating a lean company. Lean companies are not born; they are made. Companies are made lean by the constant process of seeking out and removing redundancies, wasted motion, and wasted resources. The first step to becoming a lean competitor is to question everything that happens every day at your company. By continually asking why steps are taken and what value each step adds, it is relatively easy to optimize your operations. With larger companies, we break the process down into functional areas and begin the task of becoming lean through gradual and constant improvement within each department.

The following sections will focus on individual areas within a typical company and will review some processes that can be improved at most companies.

Sales Order Processing

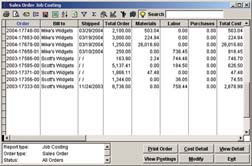

When trying to create a lean environment, customers have proven to be a mixed blessing. Nowhere is this more evident than in the order-processing stage. Customers often demand special pricing, special forms for their shipments and special markings on their products. As long as these demands can be handled once and forgotten, they are not a problem. Most modern ERP systems can print and process orders differently for different customers, calculate pricing automatically based on various factors, and generate different labels for the same product easily. Your systems should be configured so that orders can be entered by several employees. If all orders get routed to a single person for review or entry, it means you have not systematized the process properly. The "all-roads-lead-to-Fred" syndrome is the surest sign that too much human intervention is required. The human bottleneck is the biggest impediment to becoming lean and must be removed through the use of process automation in your ERP software.

Giving customers, outside brokers and salespeople online access to order status can greatly reduce the number of phone calls received to check on shipping status of orders. It is amazing how many calls companies receive for an order that was shipped only yesterday. With real-time posting of shipping transactions and a real-time link to your webpage, these types of calls can be completely eliminated. Automated links to UPS and other freight software can provide a higher level of service with less effort

Purchasing

Leaning-out the purchasing process is made more difficult for most adhesives companies because they are not the 800-lb gorilla that a big-box store or a large corporation is. Since you may not be able to mandate change to your vendors, an understanding of their requirements is essential for you to work smarter within their capabilities.A proper purchasing process will result in an order being entered once and then being simply verified at the receiving-and-invoicing stage. Most problems in purchasing are caused by shortcuts in the upfront process, therefore it is critical that part numbers, quantities, prices and due dates are entered properly at this early stage. Though it sounds simple, these items are often overlooked, which causes headaches for the accounting department, MRP calculators and others who depend on this information.

Most modern ERP systems provide the functionality to: calculate time-phased requirements based on demand from sales orders and jobs; compare these values to on-hand quantities; reorder points; and provide suggested purchase orders of raw materials and production orders for finished goods. These calculations can assist in the ability to combine orders for greater efficiencies and - even more importantly - they help to avoid last-minute ordering. Many companies spend most of their time expediting orders, which can be eliminated by planning ahead.

Be certain to share internal data with your vendors. Be able to report on vendor efficiency in terms of met due dates and orders shipped complete. Share this data with your vendors and work together to make the process better. Remember, that which can be measured can be improved.

Inventory Control

Leaning-out your inventory presents one of the best opportunities to save money. Everyone knows that inventory is expensive, but the true costs of inventory are often forgotten. The cost of inventory is far more than the actual financial carrying cost of the inventory. Inventory takes up expensive space, must be counted periodically (even when it never moves) and creates a mess when old containers of raw materials or finished goods break open or leak.Start the inventory leaning process by running an aged inventory report sorted by number of days old. Anything that has been in place for longer than the specified number of days should be reworked, segregated into a "bone yard" to be sold at reduced prices, or thrown out. This process is much like cleaning the attic. Do not get emotionally attached to your inventory - it is not an heirloom. Once this process is completed the first time, make it a part of your process to review the inventory every 30 days. This discipline will keep you from gradually returning to a frustrating situation.

Step two of the inventory leaning process is to review your sales and inventory usage figures to find items that are not moving and eliminate or replace them. After leaning the top level of items that you actually sell, be certain to eliminate the raw materials used to produce the top-level items that are no longer moving.

One of the surest ways to increase inventory accuracy is to force your ERP system to not allow negative inventory. Negative inventory is a sign that the process has not worked properly. Most companies allow negative inventory in the interest of expediting daily activities. Not allowing negatives will prevent the process from allowing a transaction that would result in negative inventory. While painful at first, these negatives provide a real opportunity to fix a process that might be broken. Negatives are caused by inaccurate bills of material, POs received but not entered into the system, etc. By forcing the issue and fixing the root causes now, you will quickly improve all areas of your operation.

Production

Over the years, more has been written about production efficiencies than probably any other part of business operations. Because of this, and the fact that production is typically fairly easy to quantify, most companies we encounter are pretty good at the actual production process. Typically, the parts that lead up to and follow production are where the greatest efficiencies can be gained.

If you are lacking in production efficiency, the best place to start is with a shop floor data-collection system to track time spent by workers and machines on each operation within a production cycle. By analyzing the time required - and, often more importantly, the time between operations - it is generally fairly easy to identify and remove bottlenecks.

Accounting

The accounting department is often overlooked when trying to create a lean environment. Leaning-out the accounting department can often have a profound impact on the rest of the company; quite often, inefficiencies in the rest of the organization roll through the process until they are fixed by Accounting.Simply put, the accounting group should be responsible for establishing controls and verifying that the controls are followed. If your accounting group is spending lots of time investigating and fixing transactions, you need to trace these problems back to their source to fix the process that caused the problem in the first place. Every problem is an opportunity to get better. Put your best people on the teams that solve the process problems. When the process problem creates downstream work, solving the problem has an enormous return on investment. Most companies find that they are too busy to fix the backhoe because they need to dig the ditch.

As the above examples demonstrate, being lean is not the result of a magic formula or even of the latest management craze covered in business books. Lean manufacturing is the result of gradual everyday improvement. Jump in today and make one small part of your business lean.

Jay Deakins is president of Deacom Inc., an ERP software company that produces accounting and ERP systems for process and mixed-mode manufacturers. Deacom builds mission-critical software that integrates your entire company. By continually focusing on simplifying complex issues, Deacom helps streamline business processes to maximize productivity and profitability. For more information, e-mail jdeakins@deacom.net.