Elastic bonding adhesives are found around the world in many industries, including construction, packaging, footwear, electronics, medical and transportation. They are essential for applications requiring strong joints without perforating substrates, a certain amount of flexibility to accommodate movement such as material expansion, protection from corrosion or the elements, and durability.

Dow Automotive Systems offers polyurethane-based elastic adhesives that provide benefits such as sealing, multi-material bonding, processing and cost advantages to suppliers and manufacturers in the transportation industry. Typical end uses for elastic adhesives include passenger vehicles, light and heavy trucks, buses, light- and high-speed rail cars, and agricultural and construction vehicles.

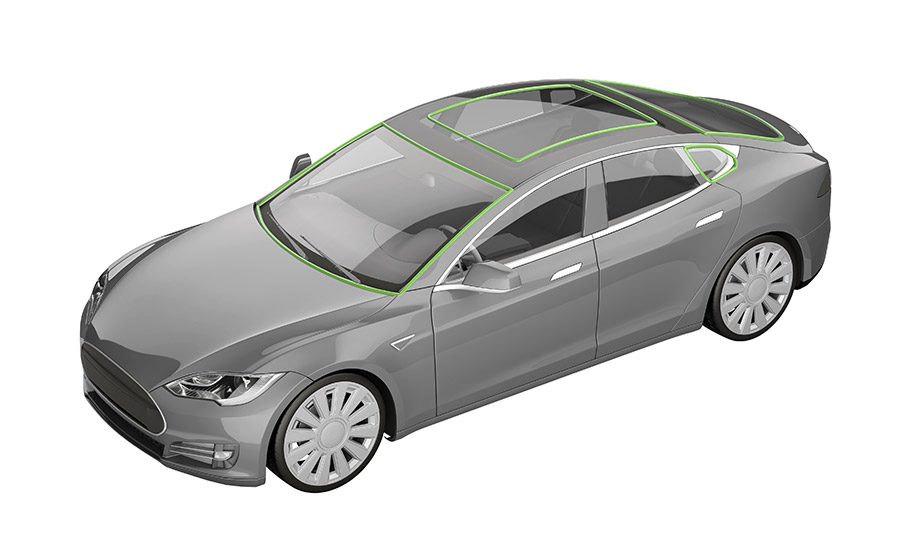

While this chemistry has been in use for more than 55 years in automotive applications alone, it is also evolving to enable innovations that will extend far into the future. In addition to windshields and backlites, manufacturers are now using elastic adhesives to bond fixed glass, glass panoramic roofs, liftgates, and hardware to vehicle bodies. An increase in demand for connectivity is also driving the addition of more in-vehicle electronics and multiple antennas on glass. Electric cars are already being powered by transparent solar cells that are part of the glass.

For future projects, customers are evaluating the feasibility of vehicles that feature more glass in larger sections, deeper angles for better aerodynamics, and wrap-around designs that appear to merge windshields with sunroofs and backlites.

What isn’t changing, however, is the importance of the glass as a structural part of the vehicle. The bonded glass adds strength, stability, stiffness and safety to all vehicles.

In addition, vehicle structures are evolving to include a broad mix of lighter-weight substrates to enable weight reduction. Paint formulations are changing rapidly to meet consumer preferences and sustainability goals. All of these trends affect the performance requirements for elastic adhesives.

Next-Generation Options

To support these advanced manufacturing requirements, high modulus and ultra-high modulus elastic adhesives have been developed to deliver stiffness and torsional rigidity, durability, thermal expansion management and environmental sealing properties. These adhesives can also bond multiple substrates to accommodate lightweight multi-material designs.

For example, a new bonding solution for global automotive manufacturers meets high-performance and safety standards in emerging markets like China, Russia, and Brazil. This new elastic adhesive, a high-performance primerless-to-paint silanated urethane, offers great stability. The adhesive is used for the structural bonding and sealing of stationary vehicle glass, including panoramic roofs, liftgates, windshields, backlites, quarter glass, glass hardware, door glass, and mixed-material bonding. Its primerless formulation helps reduce the emission impact and the carbon footprint to help meet customer sustainability targets.

Moisture-curable urethane adhesive typically requires paint primer in the glass bonding process. However, a new material* does not require a paint primer, which reduces the presence of volatile organic compounds (VOCs), simplifies the glass bonding process, reduces packaging waste and decreases production costs. In addition, it offers a long shelf life stability, as well as great adhesion capability with hard-to-bond automotive paint surfaces.

This product can be applied manually or robotically from standard or specially designed high-viscosity pump meters. The application can be done at the automotive manufacturer’s plant or at the supplier’s plant for modular supply.

The adhesive’s performance in both stability and adhesion will enable more automotive manufacturers to use the primerless-to-paint technology within their glass bonding assembly lines. Similar products have already helped the automotive industry eliminate 240,000 lbs of VOCs and

60,000 lbs of primer waste every year.

Another new elastic adhesive for glass bonding has been created to decrease VOC emissions and improve interior air quality. Customers in many markets, including commercial transportation, are concentrating on the quality of the interior air. This adhesive is making a positive contribution to that issue.

Throughout the Vehicle

Rapid-cure adhesives also support vehicle lightweighting strategies. They bond dissimilar materials, including glass-filled polypropylene, thermoplastic olefins and carbon fiber composites, to many other lightweight substrates. Thermal expansion differences can easily be managed, as can the down-gauging or down-grading of steel for cost and weight reduction.

The continuous bond line of the adhesive provides improved load transfer, resulting in improved stress distribution. Elastic adhesives also provide fast, high-strength bonding systems that address trends in modular vehicle manufacturing, mixed-material bonding and sustainable materials, creating opportunities for its use in areas beyond glass.

For example, one customer is using elastic adhesives to bond a multi-material liftgate that includes lightweight plastics, metals and glass. The adhesive joining needs included tunable open times, rapid cure capability, higher elastic properties and optimized modulus, and durable adhesion to substrates.

Often, elastic adhesives are part of a system that includes cleaners or primers for glass bonding. In these cases, a complete system from a single manufacturer should be used, rather than trying to mix and match products.

Aftermarket and Repair

Elastic adhesives continue to be an effective technology for windshield repair and replacement, and a variety of these adhesives are customized for aftermarket use. The products are available in single- and two-component systems and come in multiple package types, including kits that provide enough material to complete a day’s work. For installers, these solutions provide consistent quality, simplified application and ease of use.

Replacement bonding systems should match those that were originally specified so the vehicle can be restored to the manufacturer standards for meeting durability specifications and Federal Motor Vehicle Safety Standards for barrier, rollover, and roof-crush regulations. For aftermarket glass replacement, corrosion (e.g., rust, oxidation or other metal decay) under windshields is a safety hazard. Specialty formulated primers can provide superior flash-off times for bonding and metal corrosion protection. Corrosion undermines a vehicle’s safety functions when it develops under the windshield. A wide range of complementary bonding products with tailored mechanical properties are available to meet unique industry needs, including high-modulus/nonconductive and primerless-to-glass technologies. These help error-proof the application and eliminate the handling and use of primers on the glass side of the bond.

Auxiliary safety systems soon will play an important part in keeping drivers and passengers safe. For example, advanced driver assistance systems (ADAS), a collection of safety systems designed to work together to automate and enhance vehicle safety, add complexity to the installation and replacement of automotive windshields. Polyurethane adhesives offer proven attachment solutions for the incorporation of the cameras and sensors that are required for ADAS. These adhesives help expand the design alternatives for manufacturers and suppliers as they decide how and when to integrate the newest safety options. ASI

* BETASEAL™ 16709 glass bonding adhesive.

For more information, visit www.dowautomotive.com.