The new version of PPO resin developed by GE Plastics, called PPO SA120 resin, has a molecular weight of less than 2,500, which is nearly 90-percent lower than a typical PPO resin. Typical high-molecular-weight PPO resin, also known generically as polyphenylene ether (PPE), has been traditionally used in engineering thermoplastic blends from GE in products such as NORYL® resin and NORYL GTX® resin.

Excellent Processability and Compatibilty

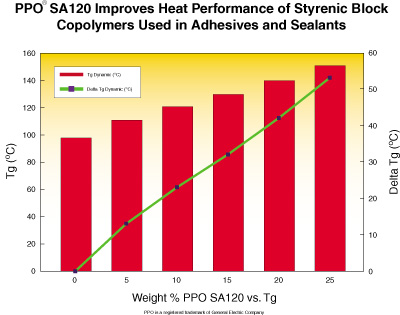

Until now, high-molecular-weight PPO resin and its high viscosity or high melt processing temperatures have limited use as an additive in some elastomeric and thermoset applications. PPO SA120 resin, on the other hand, provides excellent processability and compatibility with a host of materials outside of traditional thermoplastics markets. Physical handling is also simplified, as the material is supplied in pellet rather than powder form.Using new chemistry and processing techniques, GE Plastics has produced a material with more than a 70-percent reduction in intrinsic viscosity down to 0.12 dl/g, while maintaining its good thermal performance at a glass transition temperature (Tg) of approximately 165°C.

With the development of low-molecular-weight PPO resin, GE Plastics can now offer formulators an unprecedented ability to customize the heat performance, viscosity, fracture toughness and electrical properties of adhesives and sealants, composites, electronic components, and coatings, among others. Formulators are also expected to value PPO SA120 resin as it typically processes on conventional equipment and can simplify manufacturing of end products that offer higher performance.

Ups Service Life Above 100°C

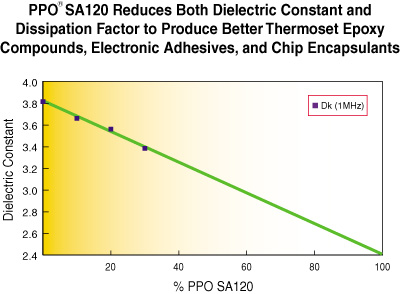

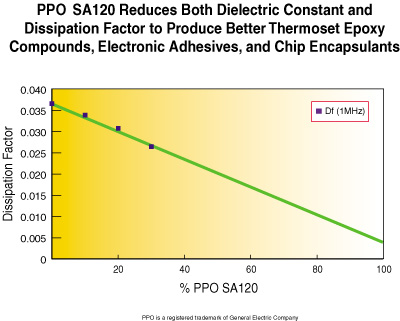

“PPO SA120 resin is a superb miscible additive for hot melt adhesive systems based on styrenic block copolymers and can boost heat performance and service temperatures well above 100°C, while maintaining good peel and tack properties,” said Benny David, Specialty PPO technical manager at GE Plastics. “For many years, the hot melt adhesives industry has been looking for a product that can give a boost in thermal performance, and now PPO SA120 resin can allow that industry to grow into high-temperature applications.“In another distinct area of epoxy-based applications, products that require enhanced toughness and electrical properties can also be improved by adding the capabilities inherent in lower-molecular-weight PPO resins. In fact, there are quite a few polymer groups that can benefit from the addition of lower-molecular-weight PPO, including thermoset cyanate esters and acrylic polymers, unsaturated polyester resins, styrene butadiene rubbers, thermoset polyurethanes, and phenolic resins as well as styrenic-based thermoplastics.

“Our capabilities to tailor viscosity and end-group functionality allow even more opportunities for companies to take advantage of the outstanding properties of PPO resin,” said David.

In addition to contributing exceptional heat resistance and electrical properties to various materials, PPO SA120 resin also lends dimensional and hydrolytic stability, chemical resistance against acids and bases, inherent flame retardancy, and low water absorption.

GE Plastics is a leading global manufacturer of high-performance engineering thermoplastics, with manufacturing facilities and technology and innovation centers around the world. GE Plastics supplies a spectrum of high-performance resins and application-development resources to help its customers achieve a competitive edge through performance and design differentiation.

For more information about PPO SA120 resins as well as other specialty PPO resins, call GE Plastics, General Electric Co., One Plastics Ave., Pittsfield, MA 01201; phone: 800-845-0600. Information can also be accessed through the GE Plastics Internet site at www.geplastics.com/ppo.