UV-Curable Acrylic Hot Melts for PSAs

Today, three types of adhesive raw materials are used for pressure sensitive adhesives (PSAs): solventborne acrylics and rubbers, aqueous dispersions, and SIS/SBS block-copolymer hot melts. Among these, the SIS/SBS hot melts show the strongest growth rates. There are two basic factors for the market success of the SIS/SBS hot melts:

- Aggressive tack and tailor-made peel adhesion by modifying with a large variety of tackifier resins and plasticizing agents;

- Economic attractiveness due to low costs of the raw materials and the coating technology, and high production speed even at high coating weights.

Although the introduction of SIS/SBS hot melts is a real success story, there are some basic disadvantages to this type of raw material that prevent them from being used for a still greater number of applications:

- Poor aging behavior (yellowing and embrittlement) caused by oxidation of residual double bonds in the polymer;

- Low film transparency that does not allow production of crystal-clear self-adhesive labels and tapes;

- Moderate heat resistance.

The established alternatives for applications where use of SIS/SBS hot melts is not possible are solventborne or waterborne adhesives. The preferred type of polymer raw material for these adhesive systems is the acrylics because they guarantee an excellent aging behavior and an optimum visual appearance.

However, these acrylic systems have specific disadvantages that limit their attractiveness, e.g., the ecological and toxicological risks of solventborne adhesives and the moderate water resistance of waterborne adhesives. Also, only slow production speeds are possible for both of the alternatives, especially at high coating weights, due to the necessary evaporation of organic solvent or water.

Considering the disadvantages of the established systems, our goal was to develop a new class of adhesive raw material for self-adhesive products that combines the attractive coating technology of the SIS/SBS hot melts with the excellent visual appearance and heat resistance of the solventborne or waterborne acrylics.

Combining Coating Technology With Acrylic Chemistry

The acResin® UV products consist of acrylic copolymers that include copolymerized photo-reactive groups. To make acResin UV coatable on carriers like paper or foil at reasonable temperatures, the molecular weight of the polymer is limited to about 200,000 g/mol. To produce an adhesive with substantial cohesion, the coated acResin raw material has to obtain a much higher molecular weight. This is achieved by UV irradiation. Under the action of UV light, the photo-reactive groups in acResin UV crosslink the acrylic polymer backbone molecules by a chemical-grafting reaction (Fig. 1). The chemical principle of acResin UV is basically different from other types of UV acrylics. acResin UV is already a polymeric raw material that achieves additional crosslinking by UV light, whereas other UV acrylics used as adhesive raw materials consist of mixtures of oligomers with monomers and photoinitiators. Such mixtures react after being coated onto the carrier in a radical polymerization of double bonds. However, disadvantages such as unpleasant odor and toxicity risks arising from residues of monomers and the photoinitiator, low coating speed, and the fact that nitrogen gas is necessary to inert the system have restricted the market success of this type of system so far.

Processing the UV Acrylic Hot Melt Resin

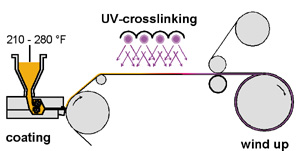

acResin UV can be processed with standard equipment for SIS/SBS hot melts that may already be available at a production site for self-adhesive articles. The remaining required investment is the modification of the machine with UV lamps. To coat acResin on the carrier, the adhesive has to be heated to 210°F – 280°F. In this temperature range, acResin UV becomes liquid enough to be coatable with common slot-die or roll systems (Fig. 2). Standard mercury, medium-pressure bulbs commonly used in other applications are typically used as the light source.

The Crosslinking Mechanism

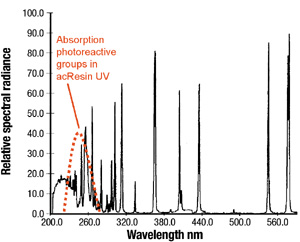

To achieve an efficient crosslinking of the acResin UV molecules, UV light with a special wavelength band is needed since the UV light has to match the UV absorption of the photo-reactive groups in acResin UV. A closer look at the crosslinking mechanism of acResin UV reveals that the concentration of the triplet radical T1 in the carbonylic function of the benzophenone group is responsible for the resulting crosslinking efficiency. Hence, the higher the T1 radical concentration, the more the photo-reactive groups will react and the higher the resulting crosslinking density will be (Fig. 3).

Tailoring the Adhesion Properties

A special feature of acResin UV is that the adhesive properties can be tailored by adjusting the UV C-dose to which the coated adhesive is exposed. The higher the UV-C dose, the higher the cohesion and the lower the adhesion. This is a consequence of the crosslinking density and makes it possible to produce a whole range of different products from one raw material just by modifying the UV C-dose. For example, acResin DS 3532 is an adhesive raw material that is well suited for two completely different applications. When crosslinked with a low UV dose, acResin DS 3532 is a good adhesive for deep-freeze labels, whereas when it is crosslinked with high UV doses, it produces an excellent adhesive for removable labels.

Deep-Freeze Labels

A UV C-dose of 3 mJ/cm2 to 5 mJ/cm2, measured with the UV Power Puck®, produces an only slightly crosslinked adhesive with an attractive tack, even at very low temperatures. Although the glass transition temperature of the polymer is very low (-75°F), the crosslinking level is already high enough to produce cohesion of the adhesive sufficient enough to cut and stamp laminate rolls without any edge-bleeding problems (Fig. 5). To obtain significantly higher quick-stick and peel values in the temperature range of 20°F to 100°F, acResin DS 3532 can be mixed with hydrocarbon tackifier resins, which do not absorb in the UV-C wavelength band, e.g., with Regalite® R-9100.

Removable Labels

Crosslinking acResin DS 3532 with a UV C-dose of 20 mJ/cm2 to 25 mJ/cm2 produces a much more cohesive, less tacky adhesive. Labels coated with such a product show excellent peel values and can be removed after use from a wide variety of different surfaces without leaving any visible residues.

Other Benefits

Besides the fact that a whole range of different products can be produced from one raw material by adjusting the UV dose, acResin UV offers many other advantages. These benefits predestine acResin UV for a large number of very interesting applications. The benefits and recommended applications for the three products in the commercially available product range are summarized as follows:- acResin DS 3532 for deep-freeze and removable labels as discussed above.

- acResin A 203 UV for applications where formulation with tackifier resins is necessary. This is true for most of the label applications.

- acResin A 258 UV for non-formulated applications. Here the focus is self-adhesive tapes. Both A 258 and A 203 acResin products can be used for coating weights up to 100 g/m2.

This article is based on a presentation made at the 24th Annual Meeting of the Adhesion Society in Williamsburg, Va., Feb. 25-28, 2001, and is published with the copyright permission of the society. Further information on the acResin UV family of resins is available from BASF Corp., 11501 Steele Creek Road, Charlotte, NC 28273; phone 704-588-5280; or visit the Web site at www.basf.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!