Low-Pressure Injection Molding With Polyamide Hot Melts Offers Key Advantages in Electrical- and Electronic-Component Manufacturing

Low-pressure molding is bringing injection-molding capability to applications previously unserved due to either cost or processing challenges. The low-pressure injection-molding process utilizes polyamide resins to allow low-pressure filling of molds. The combination of the process and material offers many benefits to manufacturing costs and finished product performance. Injection molding is no longer cost prohibitive or inflexible to product changeovers. And, sensitive electronic components can now experience the protection and security offered by over-molding.

"Mold Where No Man Has Molded Before"

Due to the low injection pressure of the molding material, over-molding can be performed on components that could not withstand the high injection pressures of traditional injection molding. Examples include circuit boards, "floating" wires or components, nylon-covered wires, and delicate sensors.

Startup/Retooling Efficiencies

Any production process today must be efficient while allowing for flexibility to meet changing customer needs. Particularly in processes involving fiber optics, electronic or electrical components, there are delicate parts to be protected, both during manufacturing and while in use. Injection molding offers manufacturers the opportunity to seal and protect components from the dangers of ingress and movement.However, starting or retooling an injection-molding process is typically an expensive endeavor. In addition to the expense of the actual injection-molding equipment, including heavy presses, there is the cost of extensive water-cooling systems and fabrication of costly steel molds.

The low-pressure molding process utilizes inexpensive mold designs and simple dispensing equipment. Low-pressure injection molding uses aluminum molds, which are quick to produce, relatively inexpensive to manufacture and easy to integrate into the production process. Due to the low injection pressures, large X-ton presses are not required for mold closure. The reduced production time and cost allow lead times to be shortened and give the manufacturer the flexibility to meet specialized customer needs. The aluminum molds' low costs and reduced set-up times make them ideal for injection molding of short-run, low-volume specialty parts.

Production Advantages

The use of a low-pressure injection-molding process leads to great production efficiencies. There is less likelihood of damage to or shifting of components when using low-viscosity polyamides. As compared to two-component potting, the molding process shortens cure time to seconds and can eliminate both potting material and the plastic enclosure that is potted. The low injection pressure increases the number of cycles per mold.

Material Provides Benefits

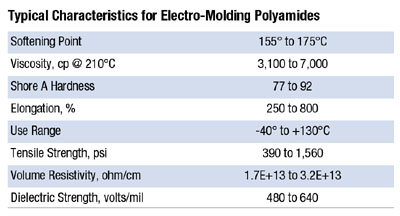

Low-pressure injection molding utilizes high-performance, low-viscosity polyamide resins. This material is able to reach small areas without high pressure, making it ideal for sensitive components. The polyamide's adhesive properties provide optimal adhesion and create an effective seal against moisture and other environmental contaminants. Polyamide's high chemical resistance to oil, diesel, grease and weak acids also enhances finished-part performance.Temperature is another favorable aspect of polyamide materials, which possess a positive balance of low- and high-temperature performance, ranging from -40 deg C to 130 deg C (see table).

Low-pressure injection molding helps protect the environment and save time. The thermoplastic polyamide material is nearly 100-percent reusable, reducing scrap. Polyamide is a non-toxic, one-part material, eliminating the mixing and metering associated with two-component epoxies. Also, low-pressure material cures instantly, whereas two-component materials can take up to 24 hours to cure.

Finished Products

Low-pressure injection molding with polyamide materials offers many benefits to the end product. Electrical and electronic components are protected from extreme elements such as heat, humidity and dust. Insulation of transformers improves performance and function. Motors and gearboxes are watertight and temperature-resistant. Applications include:- Automotive

Electronics

Appliance

Fiber Optic Components.

Weighing Your Options

The use of low-pressure injection molding for switches, sensors, circuit boards, relays, fiber optic components, electronics and electrical components provides an economical means of insulating and protecting the end product. High-performance polyamide materials protect parts from moisture and dust, increase part strength and reduce scrap. Aluminum molds decrease tooling costs and set-up time, allowing for short runs and more flexibility in mold design. Ancillary equipment, such as high-tonnage presses and chilled water-cooling systems, is no longer necessary.

Low-pressure injection molding is a proven process offering an excellent solution to the high requirements of electronic-, electrical- and fiber optic-component production in a range of applications including automotive, appliance, medical and two-component potting. This process has been successful in Europe for many years. Now we in the United States are catching on.

Low-pressure injection-molding benefits:

Additional information on low-pressure injection molding is available from Nordson Corp., Product Assembly Group, 11475 Lakefield Dr., Duluth, GA 30097; phone 800-683-2314; fax 866-667-3329; e-mail sstone@nordson.com; or visit the Web site www.nordson.com/productassembly. Or Circle No. 75.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!