Stereolithography parts can be bonded with UV-curable adhesive.

Figure 1.

Acrylate adhesives are limited by the ability to cure through opaque substrates, but most fiber-optic and stereolithographic applications do not pose this limitation. The basic mechanism forming an adhesive bond includes the cleanliness and wetting of the substrate surface, solidification of the adhesive, formation of interphase regions, design of the joint, and the control of materials and manufacturing process. Within the mechanism, the adhesive’s solidification involves the development of the polymer network that generates the cohesive forces between the two substrates. Adhesion-promoting functionalities interact with the surface of the substrate, and the polymer network binds them together, completing the bond. The adhesion-promoting components become part of the network through direct covalent bonding with the network or by polar association. The polymer network also regulates the flexibility and chemical resistance of an adhesive based on the structure.1UV-curing acrylates typically use ultraviolet radiation to adhere the parts together. Typical UV radiation sources include pressurized mercury lamps or xenon bulbs. For high-power light sources, bonding will usually occur in a fraction of a second; lower power exposures may require a longer duration. Several methods are available to quantify the degree of acrylate adhesive curing, and are used as a reference to determine recommended exposure times for various light sources. The degree of curing is useful to determine the best apparatus to properly adhere the desired parts or, if a specific apparatus is used, the length of exposure that would be required. Examples of curing units range from sophisticated tunable devices using light guides to low-power, hand-held devices with intensity of less than 10 mW/cm2. Larger curing devices supply greater than 1W/cm2intensity, curing the adhesive instantaneously. Smaller hand-held units may require up to 30 seconds of exposure.2

UV-curable epoxy adhesives will react similarly to the acrylates. The epoxies do not react as quickly as acrylates, and may require an additional thermal post treatment to complete the polymer reaction. However, the differences may be minimal with high-power exposures.

A common method of cure quantification involves the measure of functionality change during the reaction. In the case of acrylate adhesives, the acrylate double bond is converted to an aliphatic chain. Functionality change can then be measured by FTIR analysis. The acrylate’s double bonds have distinctive peaks within the IR spectrum. A liquid adhesive would contain the highest level of acrylate double bonds, and the peak would start to disappear as the polymer chain forms the structure leading to the adhesive bond. The area of the peak as a percentage to the initial area before exposure would yield the percent of cure or conversion. After a certain exposure length, the percent of conversion would plateau, indicating that the reaction has completed and the bond has formed. During the induction time, light is absorbed by the photoinitiator, causing a homocleavage of the bond, which yields two radicals. At the reaction’s onset, the radicals interact with the acrylate groups, starting a chain and propagating the radical. Those chains continue to grow. Some of the adhesive’s monomer content creates crosslinks within the system, providing the network that holds the adhesive together. As this crosslinked network starts to form, the reaction rate slows, entering a plateau region. The slowing of reaction rate is a product of available acrylate functionality being tied up within the network and not having the mobility to react with radicals at the ends of other growing chains. Higher-Tgadhesives have a much higher degree of crosslinking and will, therefore, have plateau regions leveling off around 70% acrylate conversion. In those cases, the network prevents further reaction of pendant acrylate groups. Softer or lower-Tgmaterials have a much greater mobility within the network, having an almost complete reaction of all the acrylate functionality (see Figure 1).

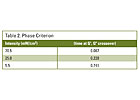

Figure 2.

The process begins with a specifically timed short interval of data collection to determine the average non-exposed acrylate content. After the specific time interval, the shutter is opened to begin the exposure. What follows is the induction time, or the time between the opening of the shutter and the first observance of a decrease in peak area. This is where the acrylate has started to react.

To demonstrate the method, a low-Tgadhesive was prepared and subjected to three different exposures with a medium-pressure mercury bulb. The area of the acrylate peak at 1407cm-1was monitored throughout the duration of exposure. The initial second of pre-exposure data was averaged to use as the initial peak area. The following data was evaluated as the percent difference from the initial value. This value is defined as the “percent acrylate conversion,” or sometimes “percent reactive acrylate unsaturation” (%RAU). The plot of acrylate conversion vs. time under three different light intensities is shown in Figure 2. The induction times and rates of conversions were different for each exposure, and are summarized in Table 1.

Table 1.

Figure 3.

Similar to the FTIR data, there is an induction time, rapid reaction and plateau. Similar times are observed between the FTIR and DMA data, indicating that the buildup of properties is occurring at the same time as the reaction of the acrylate functional groups. The induction time decreases and the rate of polymerization increases as the intensity is elevated from 5.5mW/cm2to 70.5mW/cm2. The majority of the reaction has occurred within one second of exposure.

Table 2.

Conclusion

UV-curable acrylate adhesives cure very rapidly with exposure to UV radiation. Adhesive bond formation may be monitored by tracking polymer functionality by real-time FTIR. The data shows that most exposures greater than 25mW/cm2will create an adhesive bond in less than 0.5 seconds. With a lower exposure, an induction time before the polymerization will be observed and the rate of polymerization will be slower. DMA data provides a comparison of property buildup. Comparative data indicates that the bond formation is occurring simultaneously with reaction of acrylate functional groups.For more information on UV curing, visit DSM Desotech Inc. at www.dsmdesotech.com.