Renewable Additives for Sustainable Adhesives

November 9, 2023

Renewable Additives for Sustainable Adhesives

November 9, 2023Those of you who have been involved with identifying or creating materials to meet sustainability criteria for your product line or your company already know there are many approaches possible.

This article will provide an overview of those approaches and then focus on the creation and use of renewable additives, including examples of rheology modifiers, waxes, and defoamers, as one strategy to achieve sustainable material goals.

Principles of Sustainability

Sustainability is a very broad umbrella. It entails assessing and modifying our processes so we can meet the needs of our present generation without compromising the ability of future generations to meet their own needs. Commitment to sustainable products and practices is a way to make a positive difference in our lives and our environment.

The general principles behind sustainable materials mostly concern materials to avoid, such as:

- Materials that have negative effects on human health and living organisms,

- Materials that produce greenhouse gases, and

- Materials that persist in the environment.

There are also preferential material categories, such as:

- Materials that are made from renewable carbon sources rather than fossil-derived ones.

There are many ways to achieve these sustainability principles.

- For minimizing negative health effects, you can seek so-called “clean label” materials with broad compliances.

- Greenhouse gas generation can be mitigated through sustainable sourcing, identifying the shortest possible supply chains, promotion of energy-efficient production, and creation of products with a long useful life, thereby creating less waste of energy and materials.

- Minimizing the use of persistent chemicals can include avoiding PTFE and other fluorochemicals, and opting for biodegradable materials when possible.

Not every product has all or even any of these sustainability-increasing options available to pursue, but many more products have multiple options. However, the road to maximizing sustainability may entail formulation changes and concomitant need for requalification, or costly process changes, adjustments to company culture, or all of the above. There are also concerns about whether sustainable products could be inferior in performance to the original petrochemical-based versions. Especially for those who are eager to get started but don’t have the benefit of clearly-defined targets from their market or their customers, it can be hard to know where to invest your time, money, and resources.

A Plethora of Sustainability Standards

So, which sustainability star should you hitch your wagon to? There are many standards out there.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

The obvious place to start is with whatever specifications your customers are requesting. However, if they don’t yet have a specification to meet and you are looking to improve your products now, a good place to start is the United States Environmental Protection Agency (EPA) website, at www.epa.gov. In particular, the “Greener Products” section features recommended lists of private-sector standards and ecolabels to consider. Adhesives ecolabels currently listed at www.epa.gov/greenerproducts/adhesives mostly focus on minimizing VOC emissions, and include five private-sector recommendations plus one federal ecolabel program.

That one federal program is the United States Department of Agriculture (USDA) BioPreferred® Program, which requires federal agencies and contractors to give purchasing preference to renewable, biobased products, made partly or wholly from renewable organic carbon. The BioPreferred catalog features a growing list of Federal Purchasing categories and the minimum biobased content required to source these materials for federal work. These categories include everything from office supplies to cleaning products to engine crankcase oil. Many types of coatings are also represented here. The Adhesives category specifies a minimum biobased content of 24%. There is also a general Intermediates – Chemicals category requiring a minimum of 22% biobased content.

Benefits of Sourcing Renewable Materials

Materials with renewable content can help address climate change by offering renewable alternatives to petroleum-based products. Renewable materials can be replenished fairly quickly on the order of years or decades, compared to the essentially finite resource of petroleum, which is formed over millions of years.

Renewable materials also sequester carbon, lowering the concentration of greenhouse gases in the atmosphere that contribute to climate change. Additionally, they are generally safer for people and the environment than their petroleum-based counterparts.1

And last but not least, if the biomass is sourced locally it can also support U.S. agriculture.

Renewable Definitions

Renewable, biobased materials are derived from biomass rather than fossil or petroleum sources. Biomass comes from plants and animals that were alive relatively recently, compared to millions of years ago for fossil fuel sources.

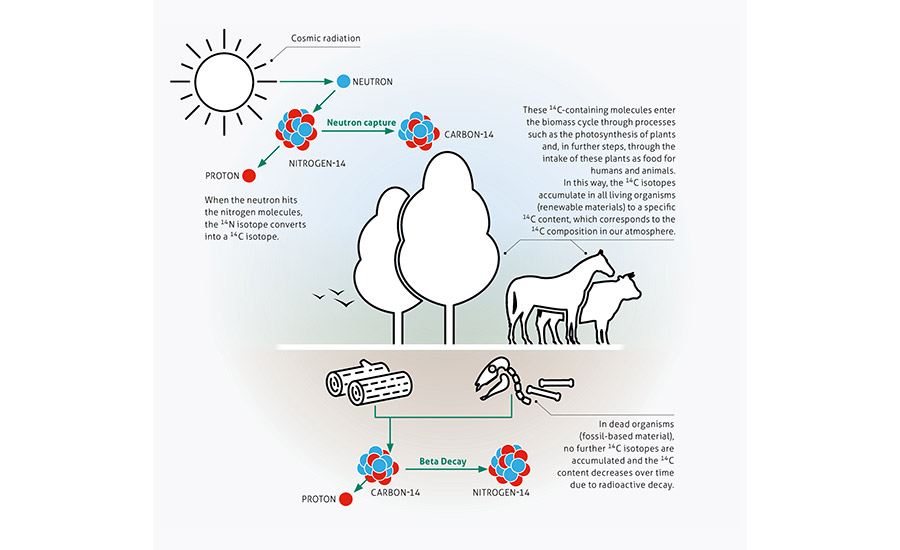

To meet USDA BioPreferred specifications, products must be certified for biobased carbon content using test method ASTM D6866. This method measures the ratio of Carbon-14 isotope to Carbon-12 in a material and compares it to a known 100% biogenic reference material.

Carbon-14 is present in our environment because of constant generation from cosmic radiation and also an additional amount from nuclear testing that started in the mid-1940s. There is some level of Carbon-14 in all living things because we take it in through breathing and eating. When a living thing dies, however, there is no more intake of new carbon, and the Carbon-14 already present in its body starts to decay to stable Nitrogen-14.

Carbon-14 has a half life of almost 6000 years, and it takes about 50,000 years for all of the measurable Carbon-14 to decay away. Fossil and petrochemical materials have been dead for millions of years, so they have no Carbon-14 remaining in them, and any carbon present is 100% Carbon-12.

It should be noted that the ASTM D6866 method reports the amount of biobased carbon as a percentage of total organic carbon in the material. So-called “neutral” components of the material such as water or inorganic carbon are excluded from the calculation. This is how it is possible to have a material with 20% active content in water that is reported as containing 100% biobased content.

Strategies for Increasing Renewable Content

There are a few ways to include or increase renewable content in additives for adhesives. One is to select materials that are already inherently renewable, such as vegetable oils and fatty acids for defoamers, or natural waxes like carnauba, soy, or rice bran wax.

Another way to increase renewable content is to replace additive components that are not inherently renewable with the same components made from a biomass feedstock, rather than from the original fossil-based or petrochemical feedstock. By taking this approach, it is possible to increase the renewable content of some additives, sometimes dramatically so.

Creating Renewable Additives

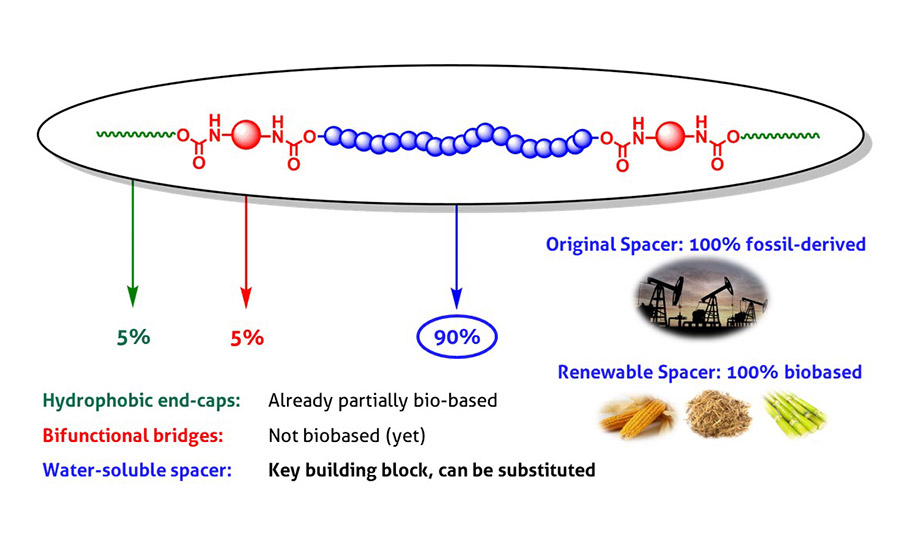

Taking the example of a HEUR-type rheology modifier as shown in Figure 3, these molecules consist of hydrophobic end caps, bifunctional bridges, and a water-soluble spacer at its heart. This hydrophilic spacer comprises a majority of the carbon in the molecule and is also a good candidate for renewable replacement. It is typically made from petrochemical sources, but by replacing it with a chemically-identical one made from biogenic feedstock such as corn, or bagasse or other agricultural by-products, the renewable content in this case is increased from less than 5% to over 90%.

One major advantage of increasing renewable organic carbon content in this way is that the new versions of the additives are chemically identical to the originals. This means they are drop-ins for performance, and they also meet the same regulatory compliances as the originals. This lowers the barriers for introduction into existing formulations and is an easy way to enhance renewable content of the final product.

Münzing has developed three new rheology modifiers with renewable content augmented from essentially zero in the originals to over 50%, 80%, and 90% that cover the gamut of performance for this type of additive, with strong pseudoplasticity, moderate pseudoplasticity, and more Newtonian thickening.2

The same approaches can be taken to maximize renewable content of wax additives. In some cases waxes can be preferentially synthesized from a renewable feedstock, such as with ethylene bis-stearamide (EBS).

The examples up to this point have shown how renewable chemical components can be used to create chemically-identical duplicates of existing additives with enhanced biobased content. However, it should be noted that unique additives can also be created from these same renewable components or moieties.

Inherently renewable plant- or animal-based waxes are also available, including polysaccharide-based biopolymers and novel vegetable waxes. Some of these renewable waxes not only meet but also surpass the performance of the petroleum-based products they are designed to replace. For instance, a new paraffin dispersion alternative with 85-95% renewable content exhibits similar hydrophobicity to paraffin when tested in a wood varnish, but the paraffin dispersion separates in storage while the renewable dispersion has the additional benefit of remaining stable.3

Defoamers are typically made up of multiple components – a carrier, actives, and emulsifiers – some of which have potential for biobased substitution. The ones with the most potential are glycols, oils, ethoxylate surfactants, and waxes. As noted with our other additives, defoamers with renewable content also span a wide range of performance attributes. There are examples suitable for use in the grind phase, in the letdown, and for post-addition, with short- or long-term persistency, high compatibility, and high efficiency. Many of these renewable defoamers are among the top-recommended additives for their applications, performing as well as or even better than other defoamers with no renewable content.

Conclusion

Choosing additives and other materials with renewable content is one simple approach to enhancing sustainability of your formulations. Existing additives can be replaced with chemically-identical versions with increased levels of renewable organic carbon, with no compromise in performance or composition and no labeling changes. Renewable materials are also already being used as a gateway for creation of novel products with superior performance.

Learn more about Münzing at www.munzing.com.

References:

- BioPreferred Program Fact Sheet [PDF], USDA BioPreferred Website https://www.biopreferred.gov/BioPreferred/faces/pages/AboutBioPreferred.xhtml#, PDF download.

- TAFIGEL® PUR 64 R, TAFIGEL® PUR 54 R, and TAFIGEL® PUR 82 R, respectively.

- WÜKONIL® NAT 1000; Bilger M, Leyh T, Schütz S. 07/08-2022. Wax Additives – True Multi-Talents. European Coatings Journal.