Spreadsheets Help Plant Managers Calculate Adhesives Savings

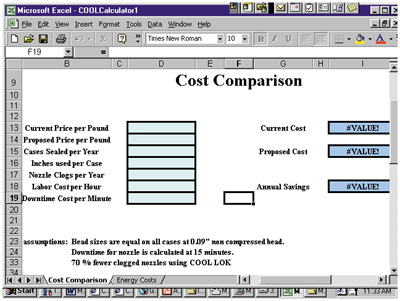

The spreadsheets help plant managers estimate savings achieved through minimizing clogged nozzles and reduced energy consumption. Clogged nozzles lead to costs for downtime and labor.

The information needed to use the spreadsheet to estimate savings by reducing clogged-nozzle problems includes the:

- current price per pound of 350degF hot melt adhesive,

- proposed price per pound of 250degF adhesive,

- number of cases or cartons sealed per year,

- inches of adhesives used per case or carton,

- nozzle-clogs experience per year (COOL-LOK adhesive has reduced tip clogging by 70%),

- labor cost per hour, and

- downtime cost per minute.

For calculating the energy savings, plant personnel only need to enter the:

- ambient temperature in the plant in degrees Fahrenheit,

- set-back temperature,

- pounds of adhesive that need to be reheated,

- number of times per year that reheating is needed and

- energy cost per kilowatt hour (an attached list includes values by state).

For a free disk containing both spreadsheets, contact National Starch and Chemical Information Center, One Matrix Drive, Monroe, NJ 08831; fax 609-409-4992; e-mail nscinquiry@salessupport.com. Or Circle No. 66.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!