Surfactants Offer Benefits to Adhesive Formulations

Surfynol® surfactants are non-foaming wetting agents based on acetylenic glycol chemistry. An example of this chemistry is Surfynol 104, a nonionic molecule with a hydrophilic section in the middle of two symmetric hydrophobic groups. This chemistry imparts very unique characteristics compared to other traditional wetting agents based on sulfosuccinate and alkylphenol ethoxylate chemistries, which in turn result in significant synergies when using Surfynol surfactants combined with Airflex® emulsion products.

Surfynol surfactants at 1% use level

* Surface tension measured at 1:1 dilution with water for all blends

**bps = bubbles per second

Surface Tension and Foam Control

Surfynol surfactants are very effective in reducing both the equilibrium and dynamic (nonequilibrium) surface tension of Airflex emulsions. This allows for exceptional wetting performance under dynamic conditions such as spray application, high speed roll coating and defect-free wetting on low-energy substrates such as plasticized PVC and treated polyolefin films. Figure 1 demonstrates the surface tension reduction capabilities of Surfynol 504 in Airflex 400 and 7200 emulsions. Similar results have been obtained with Surfynol surfactants and Airflex 410 and 426 emulsions. In addition, unlike conventional wetting agents, surfactants have very low foaming characteristics and, in some cases, act as defoamers. Therefore, adhesives based on these emulsions and surfactants will provide excellent dynamic wetting without coating defects such as fish eyes, craters and dewetting in high-speed laminating equipment, while keeping foam under control.

1% use level based on weight of emulsion.

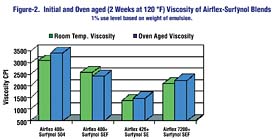

Viscosity Stability

Surfynol surfactants were added at 1% (based on weight of emulsion) in each of three Airflex emulsions. After an initial viscosity measurement on blends of the emulsions and surfactants, they were placed in an oven at 120°F for two weeks. These blends were tested for viscosity after oven age exposure. The results from Figure 2 show that the emulsions with Surfynol surfactants have excellent oven-aged viscosity stability. The viscosity change is within the standard deviation of test measurement. The adhesive formulations based on Airflex emulsions and Surfynol surfactants will provide consistent performance for various end-use applications.

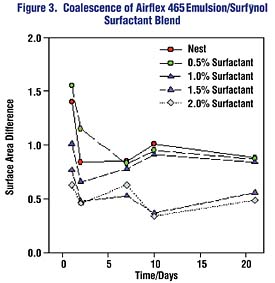

Film Coalescence and Water Resistance

In addition to their very low dynamic surface tension characteristics, Surfynol surfactants also act as coalescing agents or promoters in Airflex emulsions.Atomic force microscopy (AFM) data of blends of a Surfynol surfactant and Airflex 465 emulsion show that, above a critical surfactant concentration, the surfactant promotes coalescence as the film ages. This results in a more coherent film that is more water resistant. Figure 3 shows the film coalescence characteristics of blends of 465 and a Surfynol surfactant expressed in terms of % film area difference, which is a measure of film roughness. Lower values represent a higher degree of film coalescence. The surfactant was added in the amounts of 0, 0.5, 1, 1.5, 2 wt%. Over short periods of time, coalescence is directly related to surfactant content. At longer times, there is a critical surfactant content, which promotes coalescence.

A further advantage of the surfactants is their water resistance characteristics. After an Airflex Surfynol formulated adhesive film is dry, the Surfynol surfactant molecules adsorbed at the film/air interface exhibit a horizontal orientation, which results in a repelling effect to water droplets. Typical surfactants orient vertically at the interface and allow water droplets to reach the film and cause water sensitivity. The orientation of the Surfynol molecule results in reduced water sensitivity of the Airflex emulsion adhesive films.

Surfynol Surfactants

The Surfynol 400 series surfactants offer a unique combination of formulating benefits including wetting, defoaming and dispersion. These nonionic surfactants are produced by reacting various amounts of ethylene oxide with acetylenic diol. Adding ethylene oxide increases the hydrophilic nature of the product, modifying its water solubility, wetting and defoaming characteristics. Surfynol 420 and 440 surfactants have greater water resistance and low foaming characteristics. Surfynol 465 and 485 have higher solubility in water. Surfynol SE and SE-F are proprietary blends designed to emulsify and disperse better in water, and Surfynol 504 has the lowest dynamic surface tension of the Surfynol product line. These products were developed to promote excellent coverage in the most difficult waterborne adhesive applications. Other surfactants are available for more specialized applications.For more information, contact Air Products and Chemicals Inc., Polymer Chemicals Division, 7201 Hamilton Blvd., Allentown, PA 18195-1501; phone 800-345-3148 or 610-481-6799; fax 610-481-4381; or visit http://www.airproducts.com/polymers

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!