Safety's In The Bag

Explosion Risks

For all its advantages, the FIBC has brought with it safety issues of vital importance to processing-plant managers. Some of the products handled in FIBCs are inherently volatile, and even the most innocuous products, such as flour, are liable to explode if exposed to a sufficiently high ignition source. This problem is compounded by the fact that FIBCs are capable of attracting and holding static electricity from the bulked product. For processing plants with atmospheres containing flammable gases, solvent vapors or high dust-in-air mixtures, the need for safe FIBC discharge becomes crucial.When an FIBC is filled or discharged, there is a steady accumulation of charge within the product that is transferred to the walls of the bag. If left unchecked, this static buildup may result in low-energy discharges, known as "corona" discharges, from the surface of the FIBC. It can also lead to the charging by induction of adjacent isolated conductors, such as people or ungrounded metal.

Add to this the risk of powder being thrown into the atmosphere during the emptying process and a brush discharge could cause the product or atmosphere to ignite, resulting in a fire or an explosion. Obviously, such an occurrence would most likely lead to injury and major damage to the plant and environment. Also, any such damage would create business-interruption costs resulting from lost production, the possibility of legal action and bad publicity for the organization. The speed and scale of modern manufacturing processes, coupled with changes to raw materials, has increased the range of applications where electrostatic charge can accumulate. Any organization that stores, handles or processes flammable liquids, powders, gases, or solvents is exposed to the risk of static-related ignitions.

A number of products handled in FIBCs are extremely fine and highly invasive. This makes it necessary to ensure as close to total containment as possible of the product during discharge to prevent contamination of the local atmosphere and to maintain health and safety standards. This problem is exacerbated when the product is volatile, toxic or presents an explosion risk.

FIBC manufacturers have long been aware of these risks. Of the four basic types of bulk bag produced-Types A, B, C and D- two are specifically designed to dissipate static. The following classification seems to have been generally adopted by industry.

- Type A - These are the standard FIBCs used by companies filling and discharging products with no static problems.

- Type B - These FIBCs are manufactured from a two-ply, woven polypropylene ‘sandwich' with interwoven conductive PP monofilaments able to withstand a breakdown voltage of up to 4kV. These are the least effective bags when it comes to dealing with static.

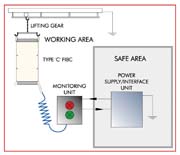

- Type C - FIBCs woven with conductive yarns that interconnect to provide a network covering the entire structure of the bag; this network is known as a Faraday cage. Grounding tabs are then attached to facilitate grounding before filling and discharge. Provided they are adequately grounded before use and the FIBC discharge is fully ground bonded, such FIBCs prevent the occurrence and propagation of brush discharges, and will also stop any spark discharges.

- Type D - This type of FIBC is made from material such as Chromiq Blue fabric that has been designed to dissipate surface charge by a combination of conductive and corona discharge, thus eliminating the need to ground the bag. It uses hundreds of small patches, each with minute spikes that are not connected. The low capacitance of the individual spikes ensures constant corona discharge, but at such a low energy as to prevent ignition of combustible atmospheres.

Current controversy surrounds the effectiveness of the Type D bag compared to the Type C. At this stage, there is no method of monitoring the operating effectiveness of the Type D FIBC, though there is such a system for the Type C.

One thing is certain, however: static-protective FIBCs are only one element of an electrostatically safe materials-handling system. There are other equally important precautions that can be taken when discharging potentially hazardous materials. For example, has the operator correctly fitted the necessary grounding clamp for the Type C FIBC? Or has the bag lost some of its static conductive properties through previous use?

It is necessary to ensure that the FIBC to be discharged is grounded, either through the FIBC support cruciform or by connecting one of the grounding lugs to a clamp, which is ground bonded to the support of the discharge unit. After a specially insulated monitoring clamp is attached to the FIBC, the system initiates the product discharging process when the resistance through the FIBC is within the range of 500V to 100V. Customers using specific FIBCs, or those who have different safety standards, may use alternative resistance ranges available through special order.

Once the parameters have been selected, the system will not operate until these conditions are met. Also, the system will immediately shut down should the parameters be exceeded at any time. This will prevent the operator from being able to fool the device by clamping the monitoring lead directly to ground. Visual indicators showing the FIBC status and its ground connection are used for ease of operation. This Static Grounding System is certified intrinsically safe, which makes it suitable for use in hazardous atmospheres, such as those containing toluene vapors and methane gas.

To eliminate the risk of dust emission during operation, specially designed and patented features are required to ensure safe discharge of the FIBC. The outlet spout of the FIBC should be connected to an inflatable seal, which will prevent dust escape during discharge. A tensioning device should be used to pneumatically stretch the outlet spout, which promotes a smooth and cylindrical path for the material to flow directly into the client's downstream process. Material could still escape when the empty bag is removed, so total discharge of product from the bag is crucial.

FIBC massagers are positioned at every corner, with an additional pair at the base of the bag. The FIBC also requires attachment to a pneumatic FIBC/liner tensioning and an inner liner clamp. The device serves to stretch the bag during discharge to eliminate the possibility of creases forming and holding residual material. The discharge unit also includes a pneumatically operated pinch bar system, designed primarily to close the outlet spout of the FIBC, thus enabling a partly discharged FIBC to be re-tied and removed from the machine.

Special Containment

Special tying of FIBC spouts and liners is required when removing empty FIBCs to ensure that minute amounts of dust are not released into the working environment. These procedures must be carried out before removal of the FIBC from the discharging unit.A height adjustment facility can also be incorporated to accommodate FIBCs of different sizes, as well as an FIBC lifting frame locator to facilitate easy and correct alignment of the FIBC into the discharge unit.

To ensure correct grounding of the FIBC cruciform, copper wires were wound around the FIBC loop-retaining sections, which were grounded through the FIBC hoist and runway beam.

The same containment and static-monitoring precautions that are required during the filling of FIBCs are also required when discharging. Correct connection of the FIBC filling spout and, where fitted, liner is vital to ensure no product emissions. In addition, liner inflation should be considered to insure satisfactory inflation of loose internal liners together with satisfactory displaced air venting during the process. As with discharging, the filling head may be secured in a containment enclosure with venting to a centralized dust extraction system or an integral HEPA filter. The same static-monitoring system may be used again, provided the FIBC is also grounded correctly.

For more information, contact Spiroflow Systems Inc., 2806 Gray Fox Road, Monroe, NC 28110; phone (704) 291-9595; or fax (704) 291-9594.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!