Polyurethane (PU)-based joint sealants have become widely used for both new build and refurbishment projects, but their importance should never be underestimated, as they play an important role in the performance of a building throughout its lifetime. It might be a small detail, yet understanding the chemical makeup of polyurethane-based sealants will result in one that will bond efficiently and seal for years.

While façade design has become increasingly sophisticated and complex, the performance, durability, and appearance remains dependent on the appropriate weather sealing. Without proper joint sealing, it would be impossible to insulate a building sufficiently or protect it from the forces of nature such as wind, rain, or snow. PU-based sealants provide a weathertight seal while minimizing air intrusion and allowing for expansion and contraction.

What are Some Advantages of Polyurethane Sealants?

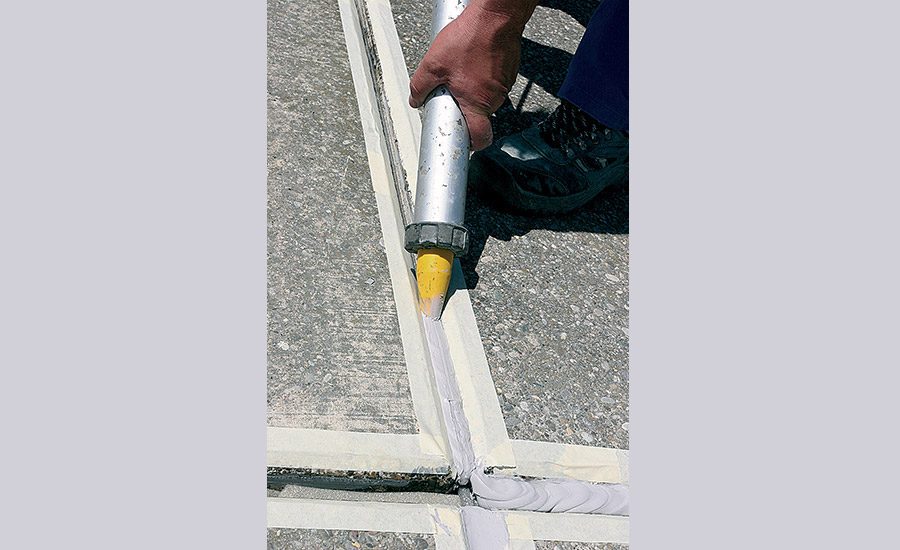

Polyurethane sealants offer many advantages, primarily versatility. PU sealants can be formulated into different kinds of products for a variety of applications, especially in large infrastructure construction projects. They can be used in various joints, such as expansion and deformation joints in the construction of buildings, tunnels, bridges, roads, and subways, as well as building projects for airports, railway stations, and power station projects.

PU sealants can also be designed for smaller application projects such as basement waterproofing, window and door installations, and swimming pool sealing. Sealants of different kinds have separate application areas and can be specified correctly based on project requirements and demands.

PU sealants offer strong bonding to wood, metal, and plastic, along with great flexibility (particularly at low temperature), recovery properties, and tear resistance. They rapidly develop strength before complete cure, helping to reduce downtime during application. PU sealants are also resistant in tough environments, both in terms of exposure to temperature extremes and in their resistance to chemicals. They are easily formulated into a variety of colors and can be overpainted after application.

The challenge of conventional moisture-cured PU products is that the reaction of the sealant with moisture can be slow and lead to the generation of carbon dioxide. These pinholes in the body of the thick section of cured sealant can make the performance of the product vulnerable to poor adhesion to the substrate, limited waterproofing, and unsuccessful sealing of joints, particularly at elevated temperature and humidity. However, this problem can be overcome.

Overcoming Challenges

In order for sealant formulators to make the most of properties for PU products, a latent hardener has been designed to be used in the formulation of one-component polyurethane sealants.* The new hardener eliminates the reaction that causes the carbon dioxide evolution by reacting preferentially with water. This activates and enhances the curing of the PU polymer in the sealant, enabling formulators to produce bubble-free cured PU sealant with maximum barrier properties.

The latent hardener is also designed to support the challenge of developing products with excellent flexibility in a variety of application environments, which is critical to maintaining a good seal in all-weather settings. The new hardener helps formulators maintain an excellent seal by ensuring that a low-to-medium modulus sealant will be able to withstand significant movement without applying stress on the sealant or the substrate.

This solution also helps formulators achieve products with high tear resistance, strong permanent adhesion, and excellent tack and non-sag properties. In addition, it helps formulators ensure that their products have improved storage and low crystalline stability.

*Incozol BH, developed by Incorez.

Custom Chemistry

The search for products that help improve the performance of formulated systems is constantly evolving. By working with adhesive and sealant formulators, it is possible to continually innovate and break new ground. When it comes to improving the bottom line for operations both large and small, custom chemicals are an important component in the creation of a better-performing product.

For more information, visit https://incorez.com.