METER MIX: Modular Gear Pump System

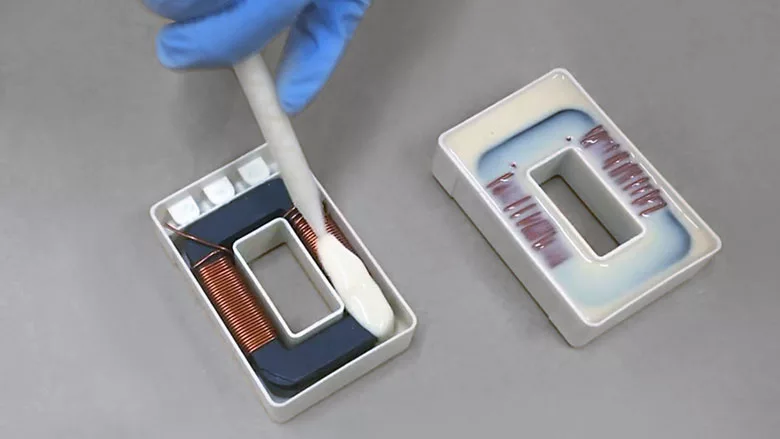

Image of METER MIX Potting. Courtesy of METER MIX.

In today's production environment, high flexibility is important. In metering and mixing processes, there is a wide variety of components requiring different flow rates, dosing quantities, and mixing ratios. Operators need a system that meets these requirements and metering and mixing systems utilizing gear pump technology provide a solution. Compared to conventional piston pumps, they are more flexible and offer more benefits for all production processes, e.g., in potting electronic components or injecting into molds for RIM applications.

The main advantages of gear pumps over piston pumps include:

• Continuous flow — dispensing larger volumes and not limited to the volume of the piston;

• Pulsation-free dispensing — lower stress on the material and the machine, which reduces errors; normally associated with pump reload and are therefore more reliable in the dispensing process.

• Easy adjustment of the mixing ratio — electronically variable and controlled via a PLC with touchscreen input;

• Accurate flow rate control — gear pumps enable consistent control at both ends of the flow rate spectrum from very small volumes up to larger flow rates; and

• Easy maintenance — gear pumps utilize rotary shaft seals and are easier and more cost effective to maintain.

The LiquidFlow 30M is a metering and mixing system from METER MIX that uses modular gear pump technology. The machine is primarily used for potting two-component resins, and it provides several benefits to customers compared to conventional piston pump systems.

Compared to piston systems, The LiquidFlow 30M is more versatile for low-mid flow applications. It can dispense continuously, as larger volumes are not limited to the size of the pistons. It consistently processes low- to medium-viscosity materials with strong process stability, meaning less stress on the machine and a more reliable dispensing process.

Customers further benefit from a high degree of flexibility, easy handling, quiet operation, and quick delivery times (typically within five weeks). With the gear pump system, customers have quick access to multiples recipes and programs. The built-in recipe function provides up to 50 pre-set shot sizes, flow rates, and ratios that can be easily stored on the control panel under the customer reference name or number.

To learn more, visit www.meter-mix.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!