Choosing the Right Filling System

Adhesive and sealant manufacturers have a variety of options when selecting a filling system for their products.

iStock / Getty Images Plus

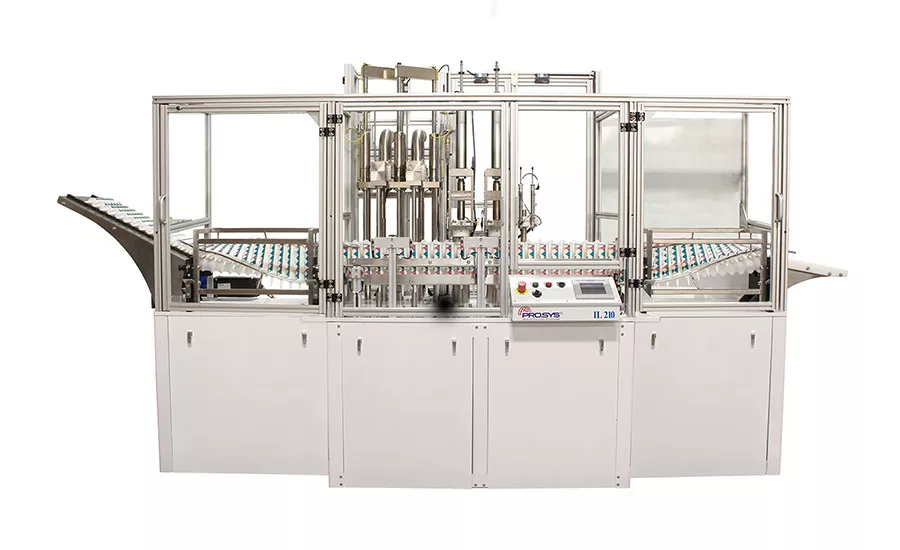

Photo of an in-line cartridge filler. Photo courtesy of ProSys Fill.

How do you select the best filling system for your adhesive or sealant? Jack Johnson, senior application engineer at ProSys Fill, recently recorded a podcast with ASI about the types of adhesive and sealant filling systems and how to choose the best system for your application. This article is a summary of some of the highlights of the podcast.

ProSys Fill LLC has designed and manufactured manual, semiautomatic and fully automated filling equipment since 1985. The company’s systems are designed for filling cartridges, squeeze tubes, syringes, rigid and custom containers. ProSys Fill serves several sectors, including the adhesives and sealants industries.

When asked what manufacturers of adhesives and sealants should consider when choosing a filling system, Johnson suggested that clients first evaluate what they want to get from their investment in a new system. Do they need to increase the speed of their operation due to growing demand? Do they want to transition from a manual to an automated system within their facilities to add more flexibility in allocating human labor resources? Or, is the company increasing its product offering and needs its filling system to accommodate additional products?

When manufacturers decide what their goal for a filling system is, the next step is to evaluate which of the types of available filling systems is right for their operation.

Manual Systems:

Options within this category include a manual system that can accommodate a single-barrel cartridge or a dual-barrel cartridge. ProSys Fill offers a manual filling system that can fill both styles. In a manual system, an operator places a cartridge into the machine and the machine automatically lifts it, fills it, and drops it down, and the operator takes it back out of the machine. Within this system, a manual plunger inserter or a manual capper can be added.

Manual systems are less expensive compared to fully automatic systems. Many startup companies will choose to go with a manual system because such a system allows them to get into filling for a smaller price point than they would see with a fully automatic machine.

Selecting the Best Filling System

For access to more podcast episodes, click here.

Semi-Automatic Systems:

A semi-automatic system can fill both styles of cartridges. According to Johnson, the semi-automatic system can be used for dual-barrel cartridges from 50 ml all the way up to 600 ml or 1500 ml. ProSys Fill’s semi-automatic system is designed as a rack system that can be built to accommodate either six or eight containers. A rack is pre-loaded with containers. Then, instead of single containers being loaded into the machine, the entire rack is loaded into the machine, which then fills and closes each container, all in a linear motion. When a cycle is complete, the rack is dispensed out, and the containers are manually unloaded from the rack. The system can accommodate other processes within the machine if required.

The manual filler and the semi-automatic filler can be pneumatic driven or servo-controlled electric driven. The choice between the two is very product dependent. The characteristics of some sealants and adhesives may require a semi-automatic system to have a servo drive system.

Fully Automatic Systems:

ProSys Fill’s fully automatic systems are on either an eight- or 12-station rotary dial or multi-head inline or liner platforms. Custom automatic systems can be used for filling both single- and dual-style cartridges. They can be automatically loaded with sorting systems, or they can be manually loaded with a manual chute. Pistons are automatically fed; plunger handles are automatically sorted and fed to the system; and cartridges are automatically unloaded. Additionally, they can load the cartridge all the way to the palletizing phase. The rotary machines have servo drive systems, and volume adjustments can be done on the fly.

Each of the three types of filling systems offers very accurate filling. This contributes to the return on investment, as significant savings can be achieved when companies are able to fill within a half of a percent accuracy and usually better.

Challenges

When asked to describe some of the common problems companies encounter when choosing a filling system, Johnson explained that some products are very hard to push. They can be very viscous or very stringy. He explained that the company offers different styles of valves that will handle very heavy product. For abrasive product, systems are made with hardened stainless steel. With very stringy product, cut-off can be a problem. Solutions for this include a solvent blast, which takes a material that customers would use to cut or clean their product and blows it through the cut-off point, allowing the product to break off. Additionally, nitrogen can used for a sealant or adhesive that is flammable.

In the podcast, Johnson describes a case study in which a customer wanted to fill three different size cartridges with three different products on the same filler. Learn how the company was able to accomplish this with minimal changeover while maintaining accurate filling by listening to the podcast.

Learn more about ProSys Fill at https://prosysfill.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!