Home » Keywords: » automation

Items Tagged with 'automation'

ARTICLES

AI and Machine Vision Are Changing Automated Dispensing

AI and machine vision are emerging as the latest technological evolution to help address inherent flaws in traditional automated dispensing.

January 16, 2026

Dynamic UV Monitoring Enhances Performance of Hot-Melt Adhesives

Collaborative development with ICAD Technology is helping to develop more robust, sustainable, and high-performing UV adhesive solutions.

January 16, 2026

Three Key Trends Shaping Adhesives and Sealants Advances

The importance of adhesives and sealants may be sometimes overlooked, but trends within these product classes matter.

December 17, 2025

AI-Driven 3D Vision Revolutionizes Adhesive Dispensing Quality Control

As electronics get smaller, manufacturers are turning to AI-powered vision systems to apply adhesives with pinpoint precision.

October 17, 2025

Automated Dispensing Improves Processing Stability in Solenoid Valve Production

Solenoid valve production has improved processing stability when automated dispensing of two-component media replaces manual mixing and dosing.

June 25, 2024

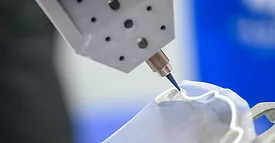

Precise Dispensing for Medical Wearables

Compact diagnostic devices require high-precision dispensing systems to apply small amounts of UV adhesives to medical printed circuit boards.

June 18, 2024

Robotic Dispenser Helps Expand Use of Pressure-Sensitive Adhesives

Each dispenser can be programmed with multiple recipes, for single- or double-sided flat, foam, or felt adhesives.

April 15, 2024

Digitalization Is Revolutionizing Chemical Industry Maintenance

The integration of digitalization into chemical industry maintenance marks a paradigm shift, offering unprecedented opportunities for efficiency, cost reduction, and sustainability.

March 11, 2024

Keep the info flowing with our newsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing