Inline Quality Control and Position Detection in Dispensing Systems

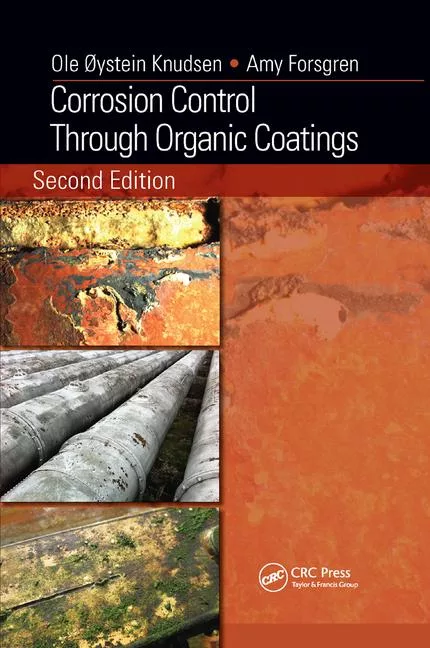

Precise position detection and correction has been placed upstream of integrated quality control, eliminating the need for complex and usually costly component fixing for the dispensing process.

Image courtesy of Scheugenpflug GmbH.

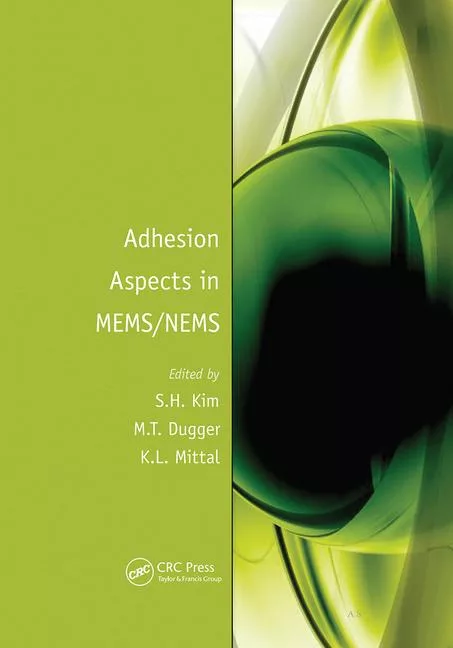

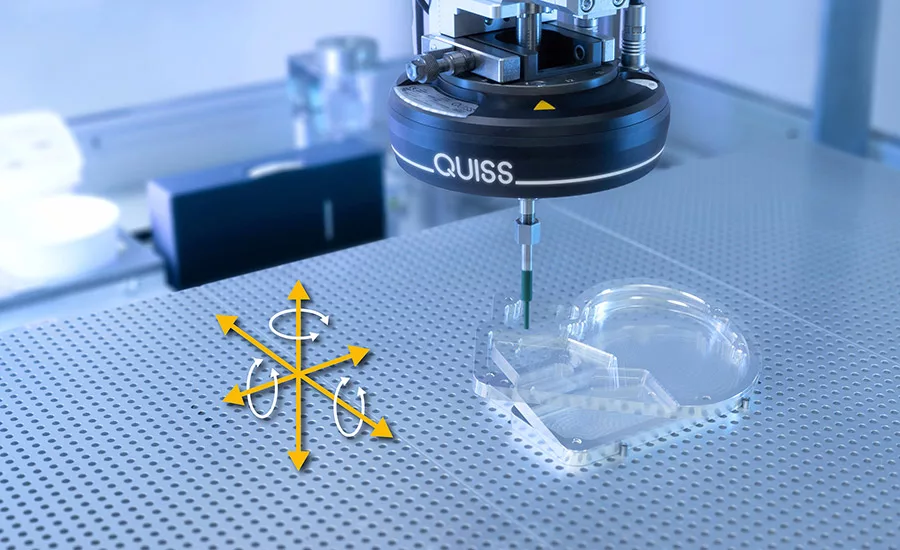

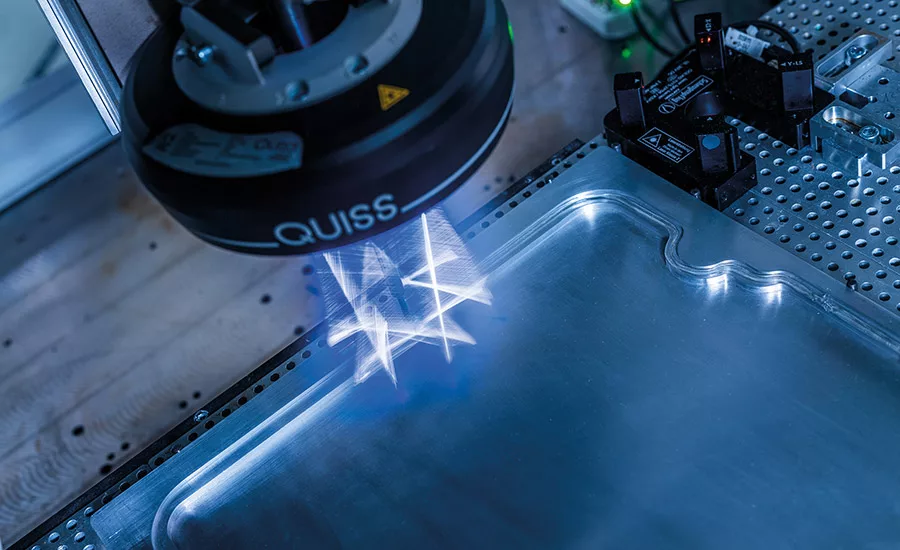

Upstream situation detection is provided in three dimensions.

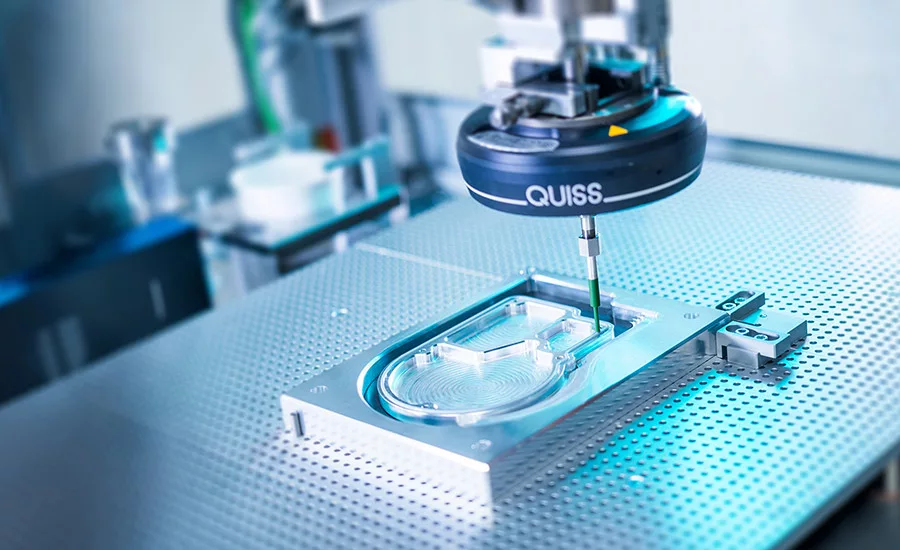

The inspection system uses six lasers as the light source to evaluate the width, continuity, and height of the bead.

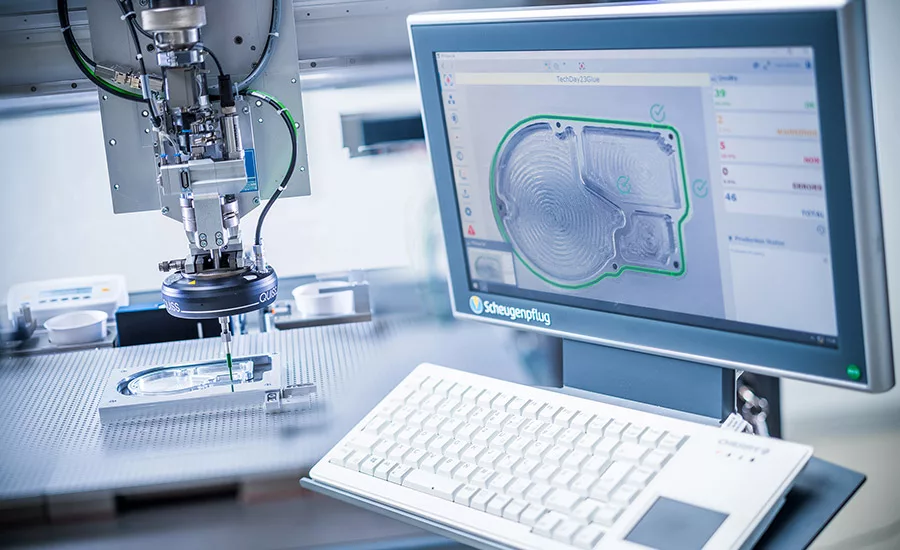

Software makes using the inspection system simple.

Dispensing systems are in continuous use and have to work with 100% accuracy. And this level of accuracy must be verifiable. Demands on electronic components continue to escalate as these components also need to operate continuously and flawlessly, especially in the automotive and medical sectors. At the same time, there is increasing pressure to automate as companies are looking to achieve the shortest possible cycle times and maximum output.

Taking Automation to a New Level

Beads must therefore be applied to each individual component or assembly with absolute precision and efficiency. Optical control options have been available for some time to avoid problems that could lead to delays or increased costs. But sometimes such systems are either incompatible or involve the additional time and effort of an extra process step at a separate location.

Precision in Any Position

Scheugenpflug offers quality control as an integral part of the dispensing cell. It has now gone one better: precise position detection and correction has been placed upstream of integrated quality control, eliminating the need for complex and usually costly component fixing for the dispensing process. With upstream position detection, RTVision.3D ensures that beads of adhesives or sealants can be accurately dispensed even if the components are not accurately positioned. To do this, the inspection system locates the component in 3D and automatically corrects the path of the axis system. With this extra automation step, 100% reliability and significant time and space savings are achieved.

Next-Level Verifiable Quality

Reliable inspection systems guarantee the quality with which adhesive and sealant beads are applied. A system that monitors the position of the component, the continuity and width of the bead and, in conjunction with RTVision.3D, the height and volume of the bead represents an important milestone in automation. The image processing systems, which are integrated as inline inspection systems, check and monitor bead application at the same time as adhesive and sealant are being applied. The sensors are mounted directly on the application head above the nozzle. Inspection takes place in real time during the dispensing process as the vision systems provide a 360-degree view of the bead all around the nozzle. RTVision.3D uses six lasers as the light source so it can evaluate not only the width and continuity of the bead but also the height as the third dimension. This 3D inline solution guarantees the quality of safety-critical, structural adhesive joints in particular.

Practical Considerations

For industrial image processing to be successful, it is important to check in advance that there is adequate contrast. All image processing applications stand or fall by the contrast between the features being checked and the background. If there is little or no contrast even the best algorithm will not help. You therefore need to agree in advance precisely what is to be used, why and how — preferably with trials directly on the system with sample components and the original application material.

User-Friendly Software

User-friendly software makes commissioning and using the inspection system very simple. Teach-in functionalities support and shorten the commissioning process as parameters can be easily set, with the OK/NOK display clearly indicating the status. Detailed result visualization ensures that any deviations can be assigned immediately and easily. Industry-proven algorithms provide smooth 24/7 operation.

Higher Production Standard

The image processing technology integrated in the dispensing system increases product quality as faulty parts never reach the customer and are not further processed. At the same time, it increases the productivity and competitiveness of production because even with higher throughput, 100% control is ensured without additional personnel costs for control. That means increased efficiency while maintaining cost effectiveness.

This solution makes production highly reliable and supports sustainable production processes. Only products that are proven to be correctly dispensed will pass to the next production step. Waste is kept to a minimum, which means reduced material consumption, reduced waste disposal costs, and less impact on the environment. With image processing integrated in the dispensing system, there is no need for a separate cell and therefore no need for extra surface area. Rapid identification and elimination of flaws leads to processes that are optimized and stabilized. This enables production processes to run more smoothly, which in turn allows for higher throughput. In addition, a wide range of different products can be manufactured on the same line. Test programs can be easily and flexibly adapted.

The systems can be seamlessly integrated in existing work processes. Ergonomic workplaces relieve employees of monotonous testing and create a positive and productive working environment.

All-in-One Solution

The all-in-one solution, which fully integrates inspection and position detection in the dispensing station, is based on in-depth process know-how and comprehensive automation expertise. With RTVision.t and RTVision.3D, plant operators benefit from a higher, fully documented level of quality. What’s more, the rapid reaction times in process monitoring increase the productivity of the plant.

Learn more about Scheugenpflug GmbH at www.scheugenpflug-dispensing.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!