Precise Dispensing for Medical Wearables

Compact diagnostic devices require high-precision dispensing systems to apply small amounts of UV adhesives to medical printed circuit boards.

image courtesy of Scheugenpflug

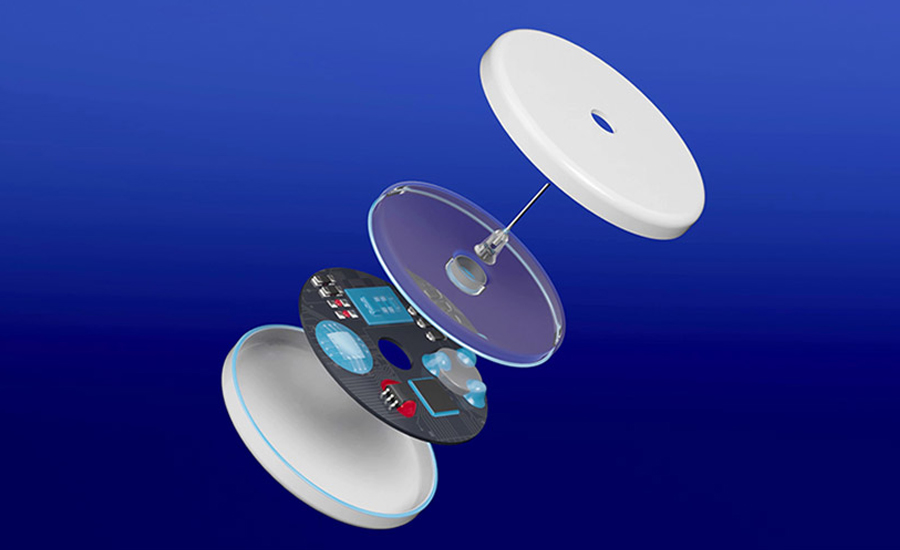

High-performance adhesion technology is a significant factor in ensuring that medical health parameters can be easily monitored in real time without any location restraints. In combination with modern sensors, it provides the basis for developing intelligent, portable, and increasingly compact diagnostic devices. Production of such wearables requires high-precision dispensing systems for applying small volumes of UV adhesives to the medical printed circuit boards as well as system concepts with integrated LED UV curing equipment.

Diabetes is now a widespread disease with several million registered sufferers throughout the world. Most diabetics still have to prick their finger whenever they need to measure their blood glucose level. With real-time continuous glucose measurement (rtCGM), however, glucose levels are measured by a sensor located in the subcutaneous tissue of the diabetes patient and transmitted to a receiving device, eliminating the unpleasant task of pricking fingers.

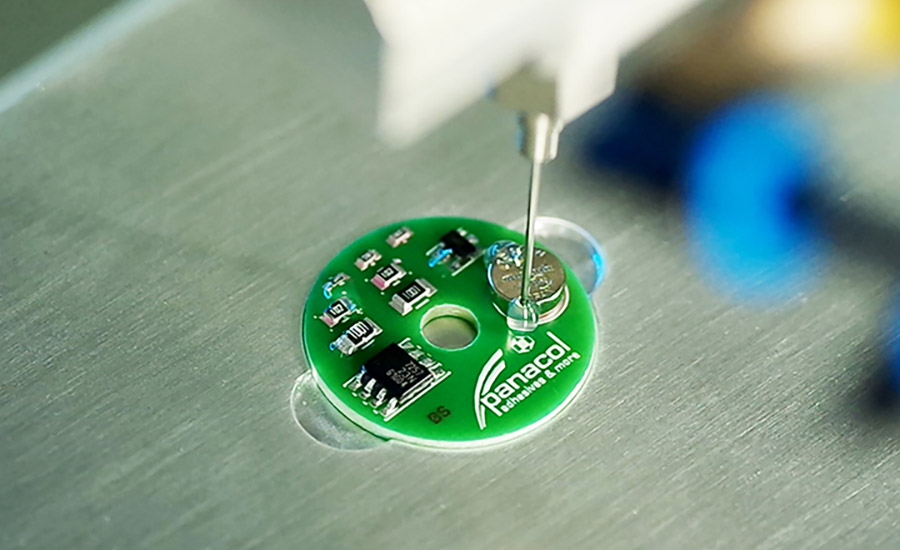

The reliability of such devices is vital. The small, printed circuit boards (PCBs), which are tightly packed with smart sensors, have to be properly protected. Dispensing system manufacturer Scheugenpflug, together with Panacol, a manufacturer of UV-curing medical adhesives, and Dr. Hönle AG, a provider of high-intensity UV LED systems, have devised a way to give glucose sensors the necessary long-term protection.

The semiconductor chips on the glucose sensor’s PCB are protected against environmental influences and mechanical stresses by what are known as glob tops. A thin protective layer of a UV or dual-curing adhesive is dispensed, which encapsulates the sensitive electronics but does not reduce the signal rate. The battery requires rtCGM systems for real-time measurement of glucose levels consist of a sensor lateral stabilization and is fixed to the PCB using the medium. Precise application is required to prevent contamination of surrounding components. The adhesive produced by Panacol meets this requirement and the bio-compatibility test requirements according to ISO 10993 and/or USP Class VI. For needle bonding, an adhesive is required that produces a strong bond with stainless steel and plastic and has high needle-withdrawal strength and good sealing properties. The material offers several viscosity options to enable custom designs.

Bonding of the plastic housing calls for precise and repeatable application of the material along the intended sealing contour (Figure 2). A sealant with high mechanical and dielectric strength is the material of choice here.

Precise Application

A low-volume dispenser head can apply minute quantities in a precise contour. Glob tops can be reliably set to 0.003 ml, dispensing accuracy of less than 0.5 % can be achieved, and extremely thin lines can be produced on the plastic housing with precise start and stop points.

The dispensing head operates on the principle of volumetric dispensing. The amount of material dispensed is determined by the geometry and stroke of the cylinders. When 2K media are used, the mixing ratio is kept constant by simultaneously discharging both cylinders into the shared mixing tube. Since the valve system allows zero-displacement dispensing, the precision of the contour remains at the same high level from start to finish. In combination with a very stable design, this enables a wide range of materials to be dispensed. Media sensitive to pressure, moisture, or shear forces can be dispensed gently without any risk of altering the material.

The entire dispensing process is monitored for test purposes by a control system consisting of new sensors and control software. For example, by comparing the target and actual dispensing pressures, fluctuations in viscosity due to a different material batch or increases in the size of the mixing tube and dispensing needle, can be reliably detected. A change in the viscosity of a component results in a pressure deviation that is detected, leading to a fault message if outside the defined tolerance range. The specific pressure level can be set for each contour so that the medium can be applied precisely and with individual presets for optimized start and stop behavior.

Integrated System

Process control is integrated in the dispensing process of the dispensing cell (Figure 3). A scale periodically checks the dispensing shot weight and needle measurement. Calibration using laser light barriers is used to monitor the position of the dosing needle. To ensure precise application on the glucose sensor, it is important that there is no material buildup on the dispensing needle. The needle is therefore cyclically positioned in the needle cleaning station.

Curing of the applied material initiates the final step of the adhesive bond. UV epoxy and acrylate curing technology ensures that curing can be achieved in seconds. The necessary UV LED systems are available in different geometries. Spot, flood, or bar devices deliver the required light intensity to ensure the shortest cycle times with productive stacks – an efficient process with low energy consumption. Different wavelengths are available so the radiation sources can be adapted to the individual processes.

The system concept makes use of an LED Spot in the 405 nm version. The arrangement of the LEDs and an electronic power controller in the LED Spot ensure high-intensity, homogeneous light distribution. The light is emitted through a square aperture of approximately 40 mm × 40 mm and is therefore aligned with the PCB of the glucose sensor with its diameter of 30 mm. Because of its compact design with a housing footprint of 55 mm × 50 mm, this high-intensity small-area spotlight can be integrated in confined spaces. The LED UV curing unit together with the dispensing head can therefore be integrated in the portal system of the dispensing cell. This allows the component to remain in one position for both dispensing and UV curing. There are no transport paths or transport delays, and therefore no risk of vibration, contamination, or adhesive spillage.

Dispensing Contours Made Easy

The software of the dispensing cell offers a user interface tailored to the application. The universal programming interface enables efficient contour creation through simple matrix and/or CNC programming with automatic code completion. The contour can be quickly duplicated using a raster function. Errors during code generation are detected, and a warning is issued if thresholds, such as the maximum dispensing speed, are exceeded.

Conclusions

In the compact layout of the dispensing cell, the low-volume dispensing head by Scheugenpflug and the Hönle LED Spot work together to precisely apply Panacol’s medical adhesives and cure them in seconds. Taking a glucose sensor as an example, this combination of products by the three companies shows what an efficient industrialized solution for medical disposables and wearables can look like.

Learn more about Scheugenpflug at www.scheugenpflug-dispensing.com.

Article images courtesy of Scheugenpflug.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1672772974&width=200)