A Unique Solution for Faster Development of Health Patches

Offering customers an opportunity to order a demo package of medical patches with a dry electrode adhesive is giving medical engineers data they need to test their initial concepts.

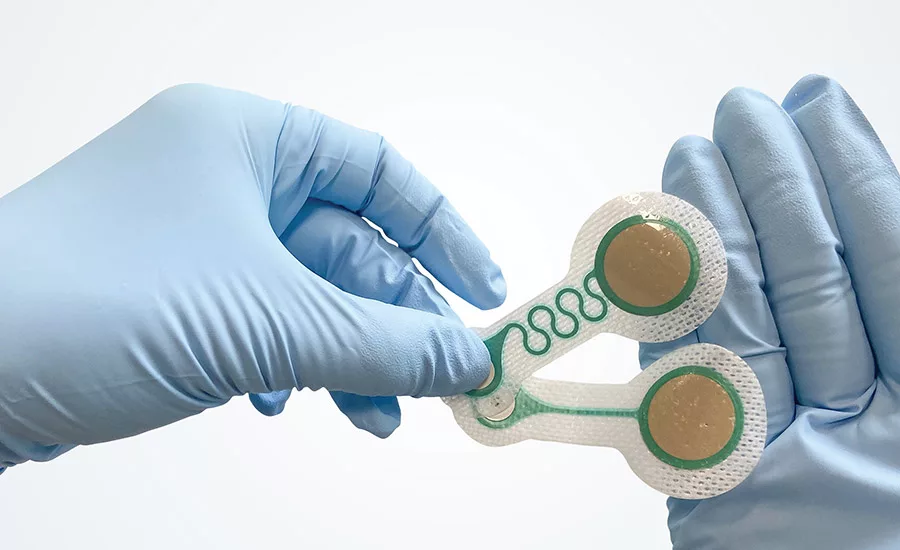

Image courtesy of Henkel.

Image courtesy of Henkel.

As the demand for digital health solutions increases, Henkel and Belgian scale-up Quad Industries, a specialist in printed electronics, have developed a new concept to enable innovations for smart health patches with accelerated speed to market at lower cost. The partners are offering a demo package designed to allow engineers to quickly test the functionalities of their concepts, significantly reducing the development time by up to three months and lowering the overall design costs.

One-Stop Shop for Innovation

In the medical industry, the demand for digital health solutions and remote patient monitoring is constantly increasing. Because of this, the market for smart health patches is on a steep growth trajectory showcasing a high innovation level. To facilitate and further speed up the innovation process for smart patches, Henkel and Quad Industries are now offering a unique demo package of 12 electrodes that can simply be ordered online. With these patches, medical engineers have all they need to test their initial concepts, allowing them to move into the phase of custom design much sooner, in a more targeted way. This approach enables a more efficient design, saving at least one prototyping cycle and the respective time and cost investment. In addition, customers can find all relevant information and materials in a few clicks, where previously, they needed to coordinate with various suppliers, from design to production.

The new approach shifts the relationship of the adhesives supplier to being a dedicated partner for the entire prototyping process, from design to proof of concept for production.

Advanced Materials

The initial focus of the demo electrode package is Electrocardiographic (ECG) monitoring, as this is often linked to different disease profiles. ECG is not only used to check the rhythm of heartbeats, but also various other values like damage of heart muscle cells, the heart’s size or the function of implanted pacemakers. It is the ambition to further expand the functionalities in the near future with different metrics and to evolve towards a multifunctional design.

The electrodes contain five different Henkel materials, including a number of new products. The demo patches contain a dry electrode adhesive that ensures the crucial electrical contact with the skin. The adhesive provides a significant added value because the health patch can be worn for multiple days, which is often a challenge in traditional patches using hydrogels. In addition, the demo electrodes will also contain a novel conductive silver ink that facilitates the stretchability of the electrode. This is particularly important to make sure the electrical signal remains consistent at high quality while at the same time providing a high comfort level for the patient. The mix of materials is based on the latest innovations to enable the design and development of thin, flexible and light-weight solutions for new smart patches or to provide an upgrade to existing technologies.

The Partnership

The demo patches are a joint design by Henkel and Quad Industries and will be produced by the latter. Both companies have started partnering in 2019, and since then have collaborated on different projects especially in the area of digital health solutions such as the development of a smart sports tracking system. In 2020, Henkel and Quad Industries were also part of the consortium behind the development of the smart health patch that allowed the remote monitoring of the vital signs of COVID-19 patients. Based on these successful projects and the strong complementarity, Quad Industries became a strategic partner in Henkel´s ecosystem in 2021 for design creation, prototyping and manufacturing of printed electronics via flatbed screen printing. Since then, the partners have tackled various projects together.

Additional information is available at www.henkel.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!