How Formulation and Coating Method Impact UV HMPSAs

Understanding how tackification and coating method impact the effectiveness of UV curing helps to ensure that UV HMPSA properties are properly balanced for their intended end-use application.

Image courtesy of GEW (EC) limited.

Commonly used in label, non-PVC graphic and specialty tape applications, UV-curable acrylic, hot-melt pressure-sensitive adhesives (UV HMPSAs) are gaining popularity due to their quick curing properties, excellent adhesion, and versatility. In particular, many converters are switching from solvent-based rubber, solvent-based acrylic, and rubber-based HMPSAs to UV HMPSAs because they offer high durability on par with most solvent-based rubber, solvent-based acrylic adhesives and overcome limitations found in rubber-based hot-melt adhesives while also keeping environmental impact to a minimum. However, curing process challenges exist with UV HMPSAs, in particular with how the formulation and coating method (direct or transfer) can impact peel, loop tack, shear, and Williams Plasticity (WP). In this paper, we will explore how tackification and coating method impact the effectiveness of UV curing with H-Bulb. Understanding how these key variables influence performance helps to ensure that UV HMPSA properties are properly balanced for their intended end-use application.

(To note: In this article, “base” refers to an unformulated UV HMPSA, and “tackified” means base with the addition of tackifier.)

UV HMPSA Formulation

When considering how UV HMPSAs will perform, it’s important first to understand how adhesive formulation impacts cure via a UV light. For example, many HMPSA components either absorb, or block, some of the UV light. This includes pigments and photoinitiators as well as any additives that have C = C bond unsaturation or aromaticity, such as tackifiers, plasticizers, or pigments.

Because these materials compete for UV light, addition of additives that absorb UV light limits the effective penetration of the UV light through the sample. This lower effective UV light dosage, especially at increasing concentrations of these additives, will limit the cure-through for the depth of the adhesive. Careful formulation is required to balance properties and also ensure the efficacy of the ingredients.

UV HMPSA Coating Method

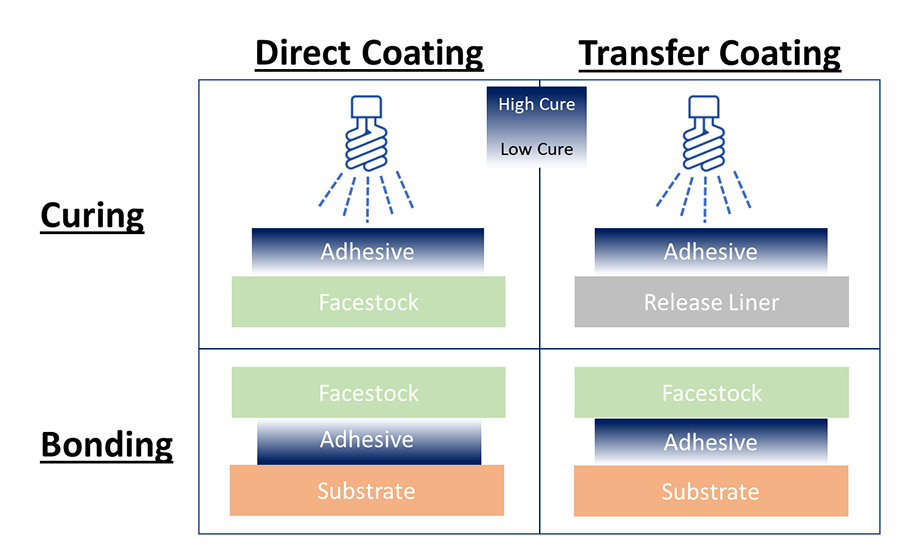

UV HMPSAs can be either direct or transfer coated during the manufacturing process. However, just like with the formulation, the coating method impacts end-use performance.

When UV HMPSAs are direct coated, the adhesive is applied directly onto the facestock. The final adhesive performance is primarily based on the directly-irradiated surface, which has a higher level of cure compared to the rest of the adhesive layer. However, when UV HMPSAs are transfer coated, the directly-irradiated adhesive surface (high cure) is then laminated to the facestock. Therefore, adhesive performance is mostly based on the low cure surface, which is the softest portion of the entire adhesive layer (see Figure 1). Since high cure adhesives favor the cohesive properties (shear), and low cure adhesives favor the adhesive properties (tack, peel), the structural differences resulting from direct- vs. transfer-coated adhesive films drive dramatic differences in all aspects of adhesive performance.

As coat weight thicknesses increase, the variation observed in peel, tack, and static shear across direct- and transfer-coated materials can be seen in the following section. This variation increases further as adhesives are tackified and there are additional materials vying for the UV light.

Further, viscoelastic properties for UV HMPSAs are substantially different when compared to traditional solvent rubber-based adhesives. Because traditional solvent rubber-based adhesive cure takes place via thermal activation or the removal of inhibiting solvent, they are much more uniformly cured across the adhesive depth. As a result, the adhesive properties between most direct-coated and transfer-coated constructions will be almost identical. Additionally, UV HMPSA cure is extremely sensitive to the dose of light at the molecular level. Higher amounts of UV light increase the level of cure, which has the effect of making the adhesive ”harder” and increasing shear.

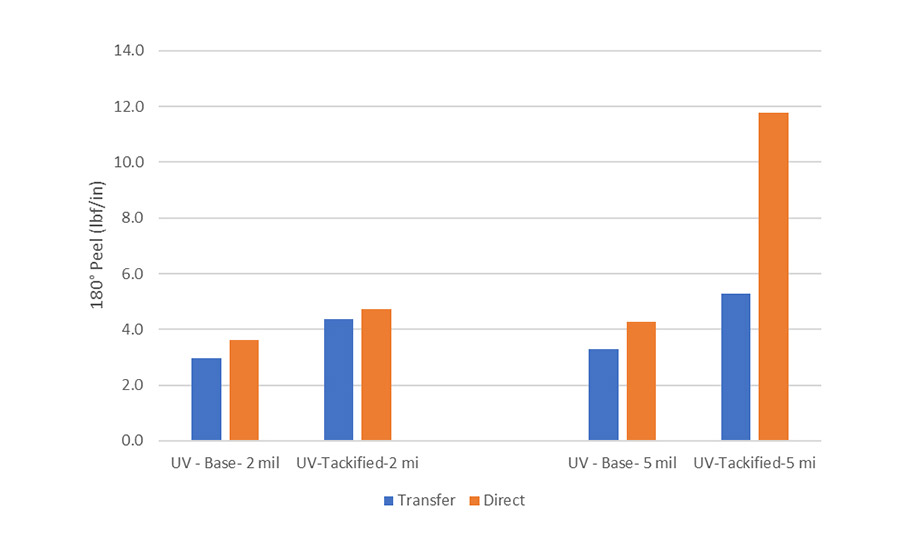

In the following sections, we will examine how peel, tack, and shear are impacted by the coating method and adhesive thickness and the addition of a tackifier. For all of the studies, the 2 mil adhesive was cured with 60 mJ/cm2 UVC light, and the 5 mil samples were cured with 100 mJ/cm2 UVC light with a H-bulb.

Peel Performance

For the 2 mil adhesive samples, the peel difference is 0.4 to 0.6 lbf/in between direct coated and transfer coated. For the 5 mil sample both direct coated and transfer coated, the peel difference is a significantly greater 1.0 to 6.5 lbf/in. The direct-coated adhesives have a lower peel value, which was attributed to the higher degree of cure at the adhesive surface. This indicates that the direct-coated material test surface (directly irradiated) may have a higher cure/modulus than the transfer-coated material test surface (indirectly irradiated). Addition of tackifier increases the UV absorption of the adhesive. Increased UV light absorption may have an impact on the penetration of light and the wavelength of light that can penetrate through the bulk of the adhesive. Peel values between direct-coated adhesives and transfer-coated adhesives that have been tackified at 5 mil have the largest differential of all the samples at 6.5 lbf/in. In both direct and transfer-coated UV HMPSAs, the addition of tackifiers causes peel strength variation between coating processes to increase when the coat weight is 5 mil or greater. The reason for this increase has to do with the variation in light exposure and the resulting crosslink density through the depth of the adhesive.

The thicker the adhesive, the bigger differential will result in comparing peel strength between direct- and transfer-coated surfaces. This is only exasperated by the addition of light-absorbing materials such as tackifiers.

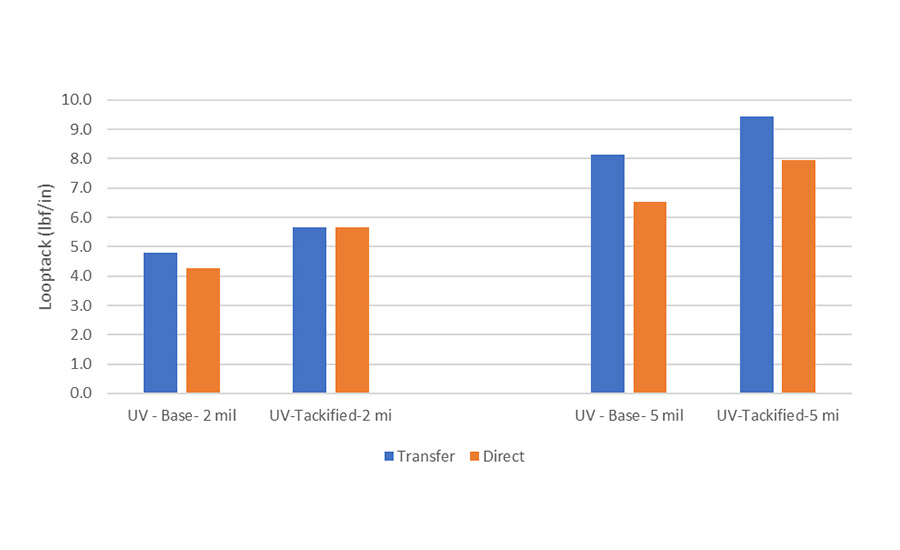

Loop Tack Performance

Like with peel, UV HMPSA loop tack performance is similarly impacted by direct or transfer coat at 5 mil coat weight, especially when UV absorbing tackifiers are present. Results for loop tack tests are shown in Figure 3 for base and tackified adhesives coated at 2 and 5 mil coat weights. The loop tack differential between direct- and transfer-coated samples increases when comparing the 5 mil to the 2 mil coat weight samples. The loop tack difference between the 2 mil sample both direct and transfer coated is 0.1 to 0.5 lbf/in. For the 5 mil sample both direct and transfer coated, the loop tack difference is significantly greater at 1.5 lbf/in. The direct-coated surface has a higher crosslink density. The high amount of UVC light that irradiates the surface efficiently crosslinks the surface of the direct-coated adhesive. As the light penetrates the adhesive, UV light is absorbed by the photoinitiator and tackifier. Therefore, lower UV doses penetrate across the adhesive. The absorption of UV light leads to less crosslinking across the adhesive from top (irradiated directly) to bottom (not irradiated).

The thicker the adhesive, the bigger differential you will see in loop tack between direct- and transfer-coated surfaces because of less crosslinking across the entire adhesive.

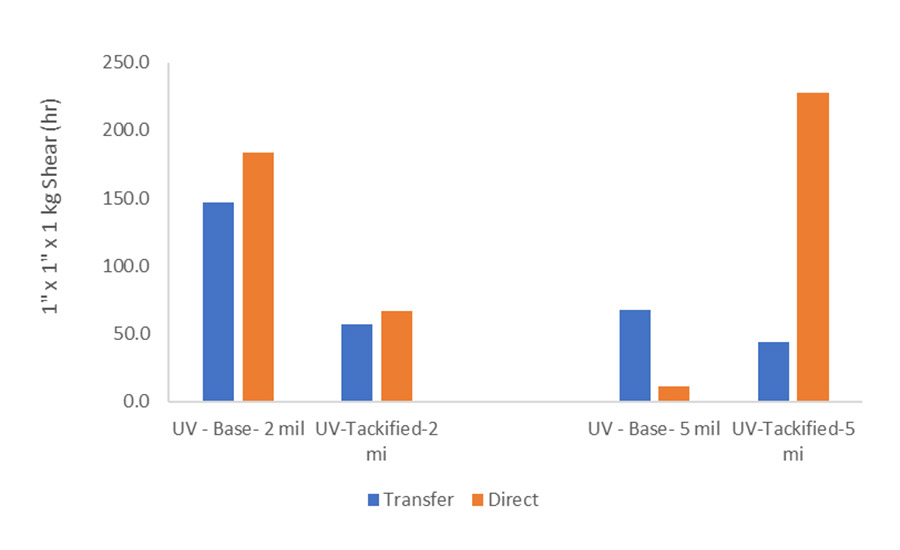

Static Shear Performance

Results for static shear tests are shown in Figure 4 for base and tackified adhesives at 2 and 5 mil coat weights. For the base adhesive, increasing the coat weight leads to a dramatic shift in shear values when comparing direct- and transfer-coated adhesives. The dramatic difference for direct-coated adhesives is attributed to the high UVC dose at the surface. The high UVC dose at the surface leads to a high modulus at the surface and poor wet out of the stainless-steel surface. Therefore, the mixed failure-mode of static shear test can be misleading when relying on shear only as a measure of the cohesive strength of the adhesive.

Tackifier added to the base adhesive impacts the surface cure and cure through the bulk of the adhesive. The direct-coated material shear outlasts the transfer-coated adhesives. Failure mode is cohesive for all samples.

If the static shear results of the 5 mil tackified are compared to the 5 mil base results, there are some noticeable differences. First, the direct-coated shears for the tackified samples are failing cohesively, versus a mix of cohesive and adhesive failure for base at 5 mil coat weights. The mixed failure mechanisms of the base indicate poor wet-out of the stainless-steel plates by the base and lower shear values result. A longer dwell time before hanging shear weights on the samples may make the data more reproducible and provide more accurate shear value for the base. Tackified samples generally show higher shear values when direct coated than the base.

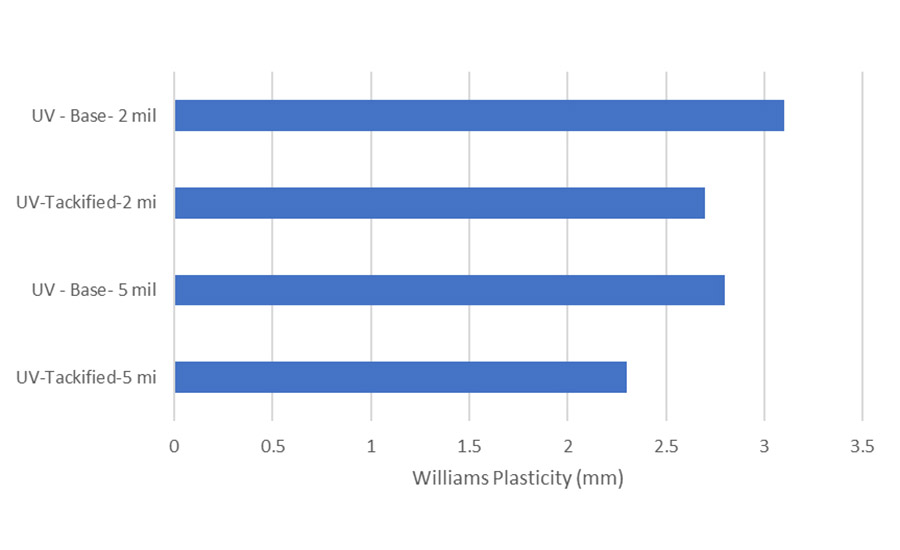

Williams Plasticity

Williams Plasticity (WP) is an indirect measure of the storage modulus of an adhesive and is not impacted by surface effects (i.e., wet-out/flow). The results of all UV HMPSAs are shown in Figure 5.

The difference in these performance characteristics while having similar WP values indicates that the samples cured with light likely have a differential modulus across the thickness of the sample. The samples have a high differential in peel, loop tack, and shear for the base samples. A differential modulus across the adhesive is highlighted by the sensitivity of shear tests of UV-cured samples to fail with mixed cohesive/adhesive failure and the large differential in loop tack. The mixed mode failure of UV-cured samples demonstrates a higher modulus at the surface that was direct coated compared to the surface that was transfer coated. For the tackified adhesive, samples coated at 2 mil coat weight demonstrate the highest WP. Increasing the coat weight leads to a lower WP result. Because 2 mil samples have a higher WP than the 5 mil thick samples, the cure across the samples is not homogenous at the dose ranges chosen for this study. The absorbance of UV light across the thickness of the adhesive makes this condition difficult to overcome with the types of UV lights chosen for this study without over-curing the surface.

Conclusion

During this work, it was shown that the adhesive formulation, adhesive thickness, and coating method all impact the adhesive properties of UV HMPSAs. In general, UV HMPSAs cured with the H-Bulb demonstrate a different adhesive performance for peel, loop tack, and shear when comparing the directly irradiated (direct-coated) and indirectly irradiated (transfer-coated) surfaces. An increase in thickness and addition of additives that absorb UV light increased the variance in performance for each coating method. A difference in crosslink density at each surface due to varied light exposure leads to different viscoelastic response during testing. Cohesive strength was increased with higher UVC dose, but shear failure mode transitioned to mixed adhesive/cohesive failure, resulting in less consistent results. The results of this study highlight the considerations for coating and formulating UV HMPSAs. An understanding of the UV HMPSA formulation and interaction with light will allow for a thoughtful process to be designed for curing the adhesive to obtain the desired performance. Additionally, UV HMPSAs performance can be adjusted to manipulate the UV HMPSAs crosslink density and therefore the viscoelastic performance.

This paper was written by the technical experts at Bostik, Inc. If you have any questions about UV HMPSAs and the information noted here, contact an expert today.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!