Plasma Treatment Increases Adhesion Reliability of Foam Sealing

Plasma treatment can reduce the curing time of a foam seal, which increased the productivity and efficiency of the sealing process.

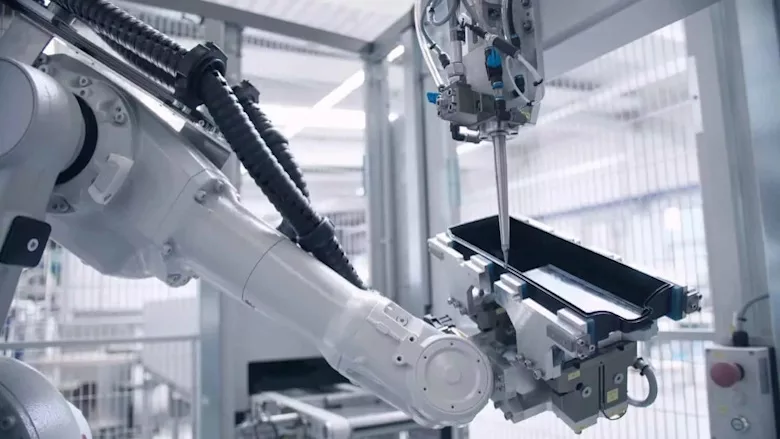

Robot dispensing sealant. Image courtesy of Robafoam Ltd.

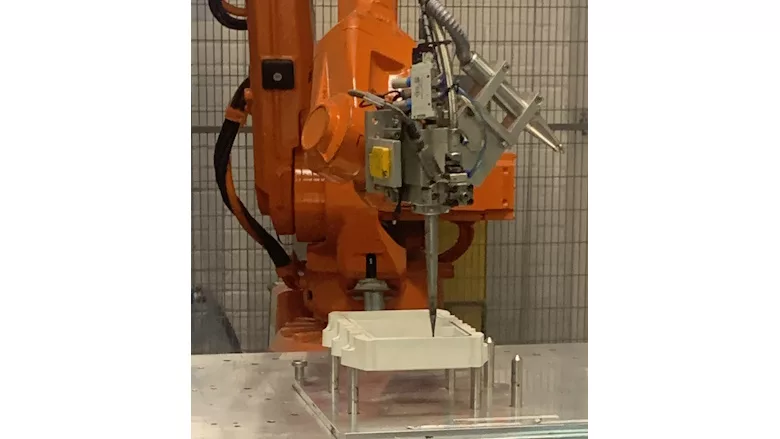

Atmospheric in-line plasma system installation at Robafoam. Image courtesy of Henniker Plasma.

Foam sealing is a process that involves applying a foam seal to a surface to prevent leakage, noise, vibration, or dust. Foam sealing is widely used in various industries, such as automotive, aerospace, and construction, to improve the quality and safety of products and components.

However, foam sealing can be challenging due to the low surface energy and contamination of some materials, which can reduce the adhesion strength and reliability of the foam seal. To overcome this challenge, Robafoam, a UK based foam sealing specialist, partnered with Henniker, a leading manufacturer of plasma treatment systems, to use its atmospheric plasma system for surface preparation before foam bonding.

A leader in foam sealing, Robafoam provides high-quality and reliable solutions for various industries. Its CeraPUR foam seal is applied by robots to create watertight, noise-reducing, and protective joints on any substrate. However, to ensure optimal adhesion of the foam seal to the component surface, the company needed a way to increase the surface energy and remove any contaminants.

Henniker is a UK-based company that specializes in plasma treatment systems and services. Plasma treatment is a fast and effective way to modify the surface properties of materials, enhancing their wettability, adhesion, and bonding performance. Plasma treatment can also clean and activate surfaces, removing any organic or inorganic contaminants that may interfere with the adhesion process.

Henniker offered Robafoam a free trial of its Cirrus Atmospheric System, a versatile plasma treatment device that can be easily integrated into existing production lines. The system uses a low-temperature plasma jet that can treat various shapes and sizes of components, without damaging or altering their bulk properties. The plasma jet delivers a stream of reactive gas species that interact with the surface molecules, creating new functional groups that increase the surface energy and polarity. The plasma jet also removes any dust, grease or oils that may be present on the surface, leaving it clean and ready for the foam seal application.

Robafoam installed the system at its site and tested it on different substrates and foam seal formulations. The company found that the plasma treatment significantly improved the adhesion strength and durability of the foam seal, as well as its resistance to environmental factors such as humidity and temperature. The plasma treatment also reduced the curing time of the foam seal, which increased the productivity and efficiency of their process.

Commenting on the partnership, a representative from Robafoam said, “We are very pleased with the assistance we got from Henniker since the beginning of our collaboration. They had the solution we were looking for and they were very helpful and friendly. We have built a strong partnership that we hope will last for a long time. Our main goal is to provide the best service to our customers, and we believe Henniker will be able to fully support us in achieving that.”

Learn more about Henniker Plasma at www.plasmatreatment.co.uk.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!